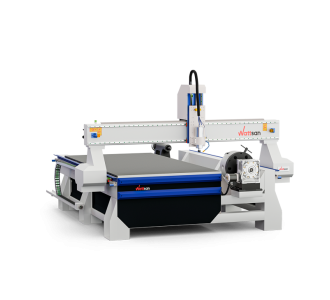

Laser machine WATTSAN NC-1612

Unique selling proposition

-

2 years warranty

-

Extensive upgrade options

-

High precision and speed

-

Framed structure

-

Lifelong support

Brief of Laser Cutting Machine for Metal 160W co2 WATTSAN NC-1612

Universal co2 laser cutting machine for metal WATTSAN NC-1612. At the beginning of the laser cutting process, a tube of gases creates a ray of light and directs it to the exit through the mirrors.

Usually CO2 machines do not cut metals. But WATTSAN NC-1612 works with all types of materials, including metals.

Materials for cutting and engraving on WATTSAN NC-1612:

fur, leather, fabrics; nonwoven materials; paper, cardboard; wood and materials based on it; plastics; rubber; Styrofoam; stone (engraving);

carbon steel.

The unique capabilities of the machine in terms of processed materials, combined with high-speed cutting and ideal beam positioning accuracy, allow it to be used in any production area.

For example: woodworking; metalworking; light and footwear industry; polygraphy; production of advertising structures; interior decor; production of packaging, rubber and paronite seals, insulation and much more.

Wattsan laser machines are thoughtfully designed

-

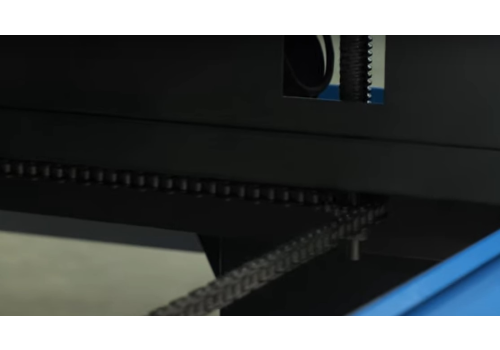

Increased thickness of housing

The stiffness of the machine is ensured not only by the frame but also by the thickness of the housing, which is especially important for large models. The long service life of the machines is also due to the thickness of the machine body.

-

Frame structure

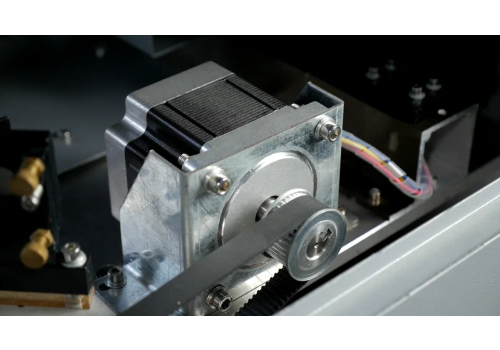

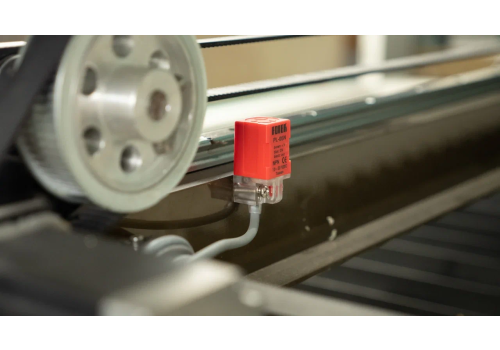

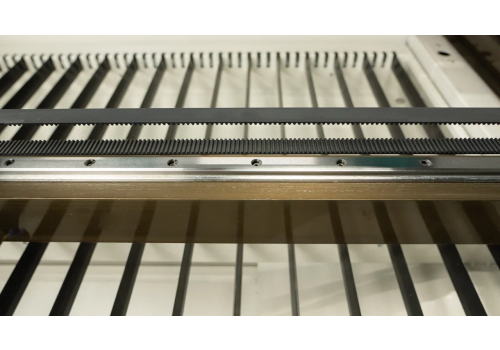

The main feature and base of Wattsan machines is a frame structure. The frame design ensures vibration-free operation at high speeds during engraving. This makes the machines less likely to require maintenance. Machine frames are continually being improved to increase the rigidity of Wattsan machines.

-

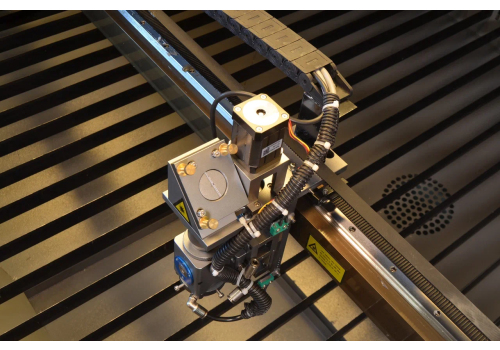

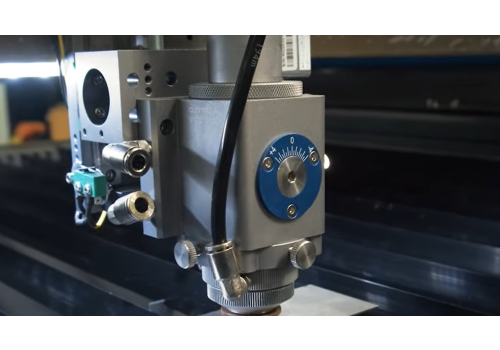

Reinforced gantry

The gantry wall thickness is 5 to 7 mm (in the corners). The gantry has a large safety margin for additional equipment with camera, autofocus or 4 laser heads. Thus, a machine with one cutting head has 4 times the safety margin.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

Technical characteristics

Ask questions

-

First of all you should decide what are you going to use the machine for, what kind of material would it be and it's size (length and thickness). This will help determine the required power of the laser tube as well as the size of the working area. You can also write or call us, we will be happy to help you choose the right machine for your tasks and budget

-

Laser engraving machine is a piece of computer numerical control (CNC) equipment that uses a laser beam to engrave necessary graphic information (image or inscriptions) on various surfaces.

-

Engraving is the effect on the material in depth. Marking on the other hand only changes the color of the material.

-

Using CO2 laser machine you can engrave any type of wood materials: solid wood, plywood, MDF and others.