Unique selling proposition

-

Pneumatic auto changing system

-

Bed with pre-annealing

-

Increased thickness of housing

-

Reinforced portal

-

Framed structure

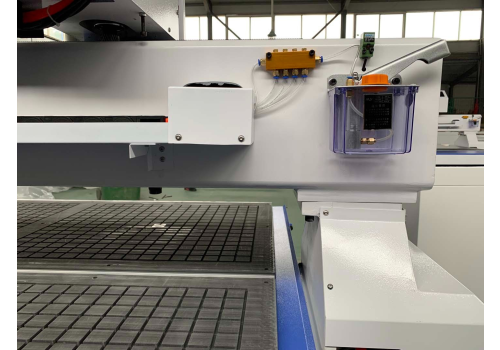

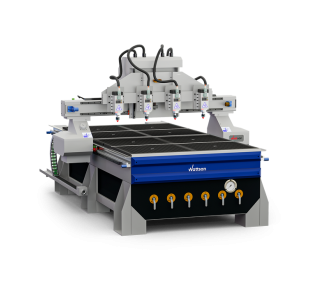

Brief of CNC Router Machine WATTSAN M3 1325

Wattsan M3 1325 CNC router machine - will reduce retooling time by 4-5 times

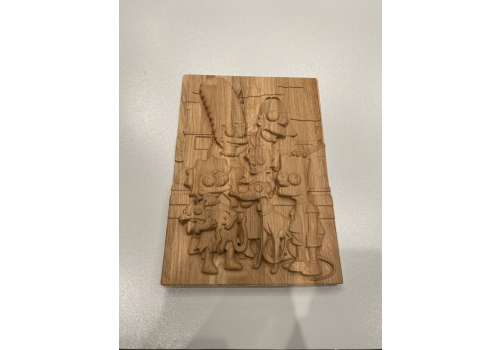

The CNC router machine WATTSAN M3 1325 cuts and engraves wood, MDF, chipboard, acrylic, plexiglass, PVC, composite, aluminum. Also, with the help of WATTSAN M3 1325, it is possible to manufacture parts for light industry, for interior and exterior decoration, souvenirs, outdoor advertising, to work with soft metals, stone, to perform woodworking and produce furniture.

The WATTSAN M3 1325 machine has a working field of 1300×2500x300 mm with a lattice table. The portal height of 300 mm makes it possible to increase the processing depth in one pass by 20%. The machine is equipped with a 7.5 kW spindle with an ER-32 collet chuck.

The increased rigidity of the portal allows the use of from one to 12 spindles, depending on the design. Significantly accelerates the material processing by reducing the retooling time by 4-5 times. The portal side pillars of the M3 series machines have increased rigidity to allow working with heavy loads, and also ensure the absence of vibrations when working at high speeds.

Wattsan machine beds will provide for 7 years of machine continuous operation

-

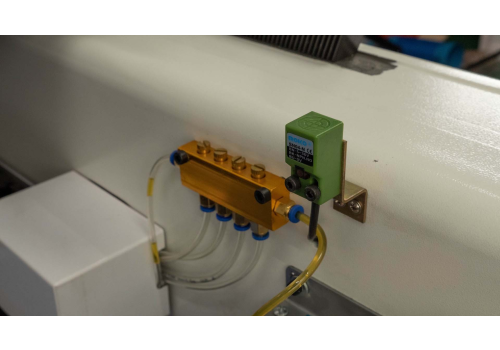

Pneumatic auto changing system

Autochange significantly speeds up the processing of the material without loss of quality and without operator intervention in the operation of the machine. Significantly speeds up the material processing process by reducing the tool change time by 4-5 times.

-

Massive machine bed

On the M1 series machine, unlike A1, the bed is reinforced and has a thickness of 10 mm, which gives high strength and stability of the frame structure and provides 10 years of work without distortion and deformation. And the stiffeners increase the stability of the frame and its tensile strength.

-

Reinforced portal

The portal side pillars have increased rigidity to allow working with heavy loads, and also ensure the absence of vibrations when working at high speeds. It allows you to use from 1 to 12 spindles, depending on the machine design.

-

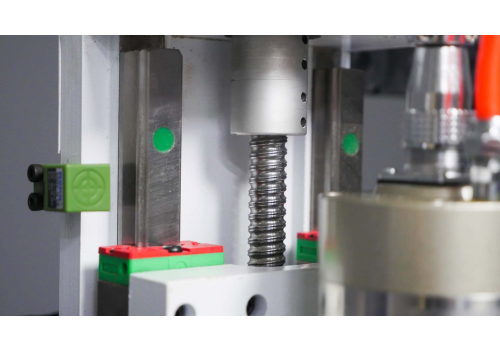

Planetary gear

Milling machines of the M series are equipped with Shimpo planetary gearboxes. They are designed to work with high loads, converting the torque from the servo motor and transferring it to the skew gear, which drives the portal movement. It is used in machines for cutting hard wood and soft metals.

-

Vacuum table

The M-series machines are equipped with a vacuum table, which allows you to quickly fix the sheet material on the table surface. Due to the hard pull, the vacuum table not only fixes, but also aligns thin-sheet materials. For a high-quality result of work, it is very important that the surface of the processed material is smooth.

-

HIWIN guides

Wattsan machines are equipped with HIWIN guides. They are distinguished by their quality and reliability, unlike analogues. Four closed rows of bearings are 30% superior to similar designs in terms of load capacity and rigidity.

-

Two-phase stepper motor

These motors are responsible for the machine movement along the Y, X and Z axes. Such motors usually do not break down and are easily replaced. At the request of the customer, the machine is equipped with a stepper motor, a hybrid stepper motor or a servo motor.

Firm frame structure of Wattsan machines

During the machine operation inertia of gentry motion is transferred to the frame which is subjected to significant loads. Therefore material and structure of the machine play a significant role in securing the machine against deformation and breakage.

-

All frames undergo multi-stage heat treatment within a day followed by milling. Furnace annealing guarantees a frame service life of more than 7 years.

-

All-welded frame of steel profile provides the right level of rigidity and vibration resistance. High strength and resistance of the frame ensure 10 years of operation without distortion and deformation.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.