Hydraulisk CNC-bukkepresse WATTSAN HB 6325

Brief of Hydralisk kantpresse HB 6325

WATTSAN H-buk

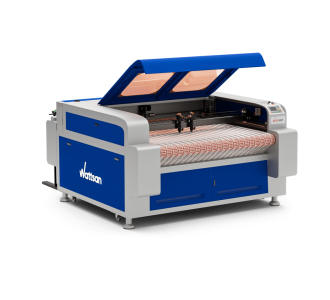

Den hydrauliske kantpresse Wattsan H-bend er designet til at udføre bukning af metalplader i forskellige størrelser og tykkelser uden forvarmning af metallet. Helsvejset konstruktion med øget sikkerhedsmargin, lineære føringer, smart hydraulik samt fire aktive uafhængige arbejdsakser i kombination med et motoriseret kompenseringssystem for stråleafbøjning garanterer perfekt repeterbarhed og høj kvalitet af de færdige produkter.

Brug af forskellige kombinationer af matricer og stempler gør det muligt at bøje i næsten enhver vinkel, hvilket udvider produktionsmulighederne. Denne klasse af metalbearbejdningsudstyr er ideel til virksomheder med et stort produktsortiment og -mængder.

Stabilitet i arkets position ved hvert bøjningstrin

Købsprocedure

-

Udvalg

Vi hjælper dig med at træffe dit valg af en maskine, der matcher dine behov

-

Sender faktura

Vi aftaler det komplette sæt af maskinen og afsendelse af fakturaen med de endelige omkostninger for udstyret.

-

Betaling

Fuldstændig hvis maskinen er på lager. 50% forud 50% ved leveringen hvis maskinen ikke er på lager.

-

Vi tjekker maskinen

3-trins kvalitetskontrol: på Wattsan-fabrikken, på vores lager i Holland, før levering.

-

Levering eller afhentning

Enten et transportfirma eller du henter maskinen fra vores lager.

-

Lydningsudstyr

Vi er her for at hjælpe dig, når du har brug for support.

Erfaringer fra entusiastiske bloggere

Tekniske egenskaber

OFTE STILLEDE SPØRGSMÅL

-

T-Bend-serien refererer til NC-torsionspresserne. De er mest afhængige af kraften fra håndtag og fjedre. Det gør dem ikke til den mest præcise type, men de er stærke og pålidelige nok til grundlæggende opgaver.

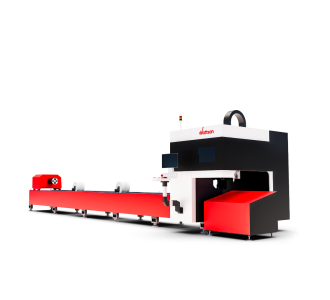

H-Bend-modellerne er hydrauliske banderoleringsmaskiner. De arbejder med olie og hydrauliske cylindre, og teknologien giver mulighed for præcis styring af den anvendte kraft. Desuden kan hydrauliske kantpressere håndtere sværere bøjninger.

S-Bend står for Servo-kantpresser. Blandt alle kantpresser er dette det mest præcise og støjsvage udstyr. Det er også det mest miljøvenlige: Det bruger elektricitet til bevægelse og bukning, mens det bruger mindre energi end en hydraulisk. Servomotorerne styrer stemplets bevægelse, hvilket giver den højeste grad af præcision.

-

Det er baseret på din produktion og opgavens kompleksitet.

Hvis du har et lille værksted eller en nyetableret virksomhed, skal du vælge T-Bend-serien. Og hvis du har brug for at udføre grundlæggende opgaver ved lavvolumenproduktion, som f.eks. at lave metalborde, grill og enkle dele, vil denne maskine fungere godt.

Hvis du leder efter en maskine, der kan arbejde med højvolumenproduktion af biler og rumfart med strenge krav til nøjagtighed, så har du brug for H-Bend-serien. Og S-Bend kan give dig endnu mere effektivitet, da den er hurtigere og kan skabe ideelle betingelser for serieproduktion.

-

Der findes værktøjer, kaldet punch og die, som skaber specifikke vinkler, når ark presses mellem dem. Mængden af disse værktøjer giver enten fleksibel produktion eller strengt ensrettede maskiner, hvilket kan være meget nyttigt.

-

Nogle af maskinerne kan være udstyret med ekstra værktøjer.

Først værktøjer til sikkerhed: laserbeskyttelsessystem og lysgardin. De eliminerer eller reducerer begge så meget som muligt enhver risiko for brugeren.

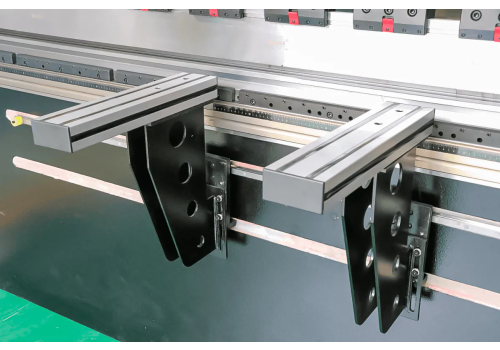

For det andet er der dobbeltsidet quick-release-spænding. Det gør det meget nemmere at montere de øverste værktøjer og at fjerne dem igen. Alt i alt reducerer det produktionstiden.

For det tredje et automatisk lasermålesystem til bukkevinkler. Det hjælper med at korrigere mulige fejl og gøre slutprodukterne præcise.

Der er et par stykker mere. Hvis du vil vide mere om dem og finde ud af, om du har brug for dem eller ej, så kontakt vores ledere!

-

Det er faktisk ret nemt at passe på dette udstyr. Der er et par enkle ting, der skal gøres:

— Rengør kantpressen med jævne mellemrum for at fjerne snavs, støv osv. så det ikke ophobes.

— Hold øje med komponenterne, og skift dem i tide;

— En gang om året eller endnu sjældnere kan en hydraulisk presse kræve olietjek og -skift;

— Servobremser skal smøres regelmæssigt. Bortset fra det—er der ikke meget at vedligeholde.