- Main

- Equipment catalog

- CNC Router

- WATTSAN A1 1616

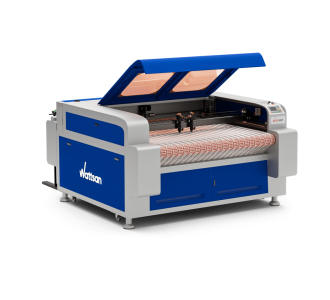

CNC router machine WATTSAN A1 1616

- Working area:

- 1600x1600 mm

- Spindle:

- 3 kW

- Machine size:

- 2260 x 2200 x 1662 mm

- Weight:

- 590 kg

Get the machine ON ORDER and SAVE UP TO 2000 €

Receive:

- 7% discount;

- DSP RichAuto A11 TeYu S&A 3000 chiller (for models 6090, 1313, 1325, or 1616)*

- Upgrade for the stepper motors—a feedback system! (for models 2030, 2040, or 2060)*

*Fully paid

Unique selling proposition

-

Extensive upgrade options

-

Showroom and Demo

-

T-slot rack coating

-

Belt gear

-

Framed structure

Brief of CNC Router Machine WATTSAN A1 1616

Milling machine Wattsan A1 1616 — medium-format CNC router machine

The CNC router machine WATTSAN A1 1616 performs cutting and engraving as well as 3D milling.

The machine is an excellent choice for: the production of parts in light industry; the woodworking industry and the production of furniture, outdoor advertising, the manufacture of souvenirs and decorative items. This machine can produce doors, furniture, equipment parts and gaskets made of paronite, the bases of exhibition stands, LED signs and light boxes, souvenirs, etc.

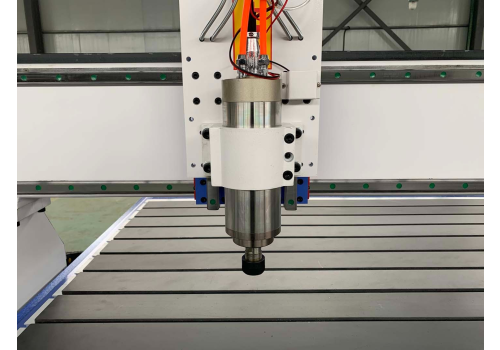

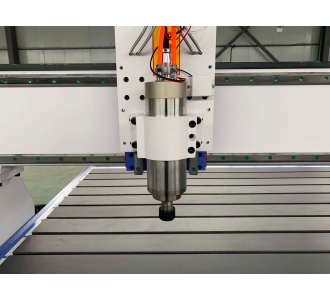

The WATTSAN A1 1616 machine has a working field of 1600×1600x200 mm with a lattice table. But if you want to process deeper products, we advise you to consider the WATTSAN M1 1616 model. The standard equipment of the Wattsan A1 1616 machine includes a spindle with an ER-20 collet chuck and a power of 3 kW. And two-phase stepper motors are responsible for precise movements.

Multi-stage heat treatment and annealing of the bed in the furnace make it possible to equip Wattsan machines with a 4.5 kW spindle and thus speed up production.

Materials

-

– milling

-

Brass

-

Paronite

-

Copper

-

Aluminium

-

MDF

-

Plexiglass (Acrylic)

-

Foam rubber

-

Plastic

-

Chipboard

-

Plywood

-

Wood

Wattsan machine beds will provide for 7 years of machine continuous operation

-

Annealing of the bed

The solid-cast machine bed provides the required level of rigidity and vibration resistance. For the durability of the machine frame structure we anneal it in a special furnace for stress relief. Furnace tempering guarantees the service life of the frame for more than 10 years.

-

HIWIN guides

Wattsan machines are equipped with HIWIN guides. They are distinguished by their quality and reliability, unlike analogues. Four closed rows of bearings are 30% superior to similar designs in terms of load capacity and rigidity.

-

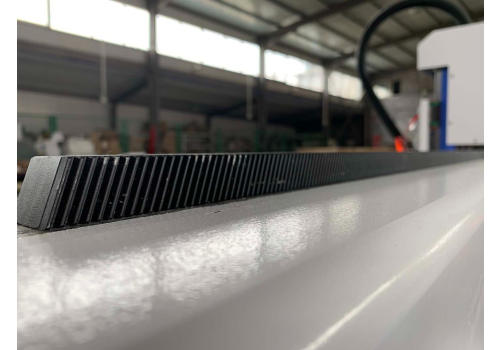

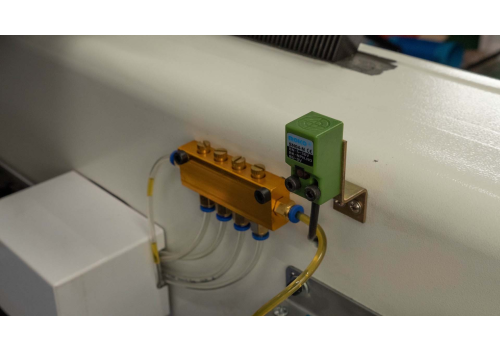

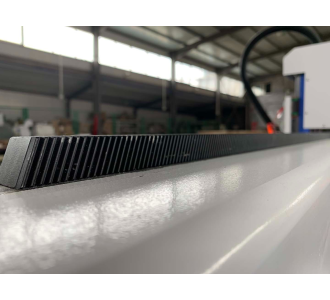

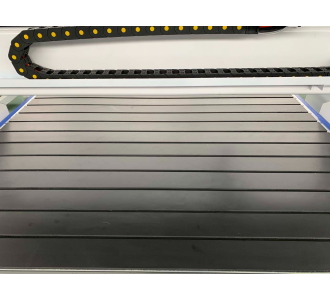

Rack table

The working field of the machine has a special T-slot rack coating. The standard shaped longitudinal grooves of this coating make it possible to fix the material with a mechanical holdback, bolts or clamps.

-

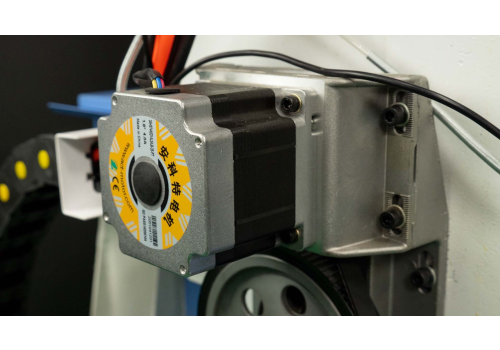

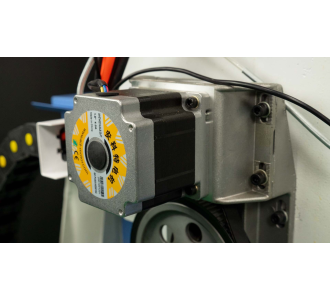

Two-phase stepper motor

These motors are responsible for the machine movement along the Y, X and Z axes. Such motors usually do not break down and are easily replaced. At the request of the customer, the machine is equipped with a stepper motor, a hybrid stepper motor or a servo motor.

-

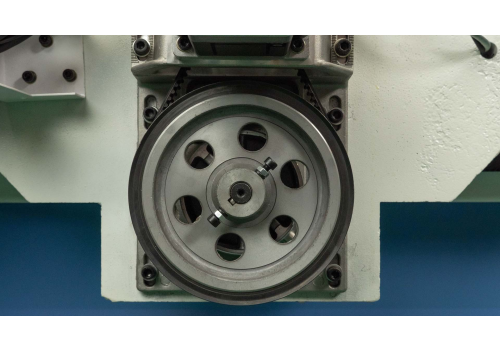

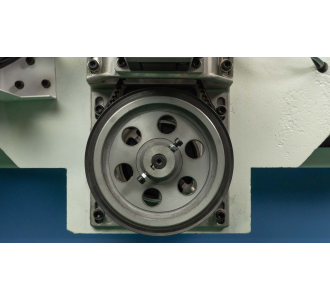

Belt gear

The A-series models are equipped with belt gears, which increases the service life of the engine and compensates for inaccuracies. These gears are very easy to replace and maintain and work silently. The optimal solution for processing soft wood and plastic.

Firm frame structure of Wattsan machines

During the machine operation inertia of gentry motion is transferred to the frame which is subjected to significant loads. Therefore material and structure of the machine play a significant role in securing the machine against deformation and breakage.

-

All frames undergo multi-stage heat treatment within a day followed by milling. Furnace annealing guarantees a frame service life of more than 7 years.

-

All-welded frame of steel profile provides the right level of rigidity and vibration resistance. High strength and resistance of the frame ensure 10 years of operation without distortion and deformation.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

-

This laser engraver can engrave without any problem. How fast and easy it is able to customize products!

Riccardo Muscarella

Riccardo Muscarella

-

Machine has a perfectly flat surface. It makes repetitive work easier for me!

Matteo Moras

Matteo Moras

-

Great job done within an hour. Thanks to the speed of the laser CO2 machine.

Roberto D'Adago

Roberto D'Adago

-

This model is great, and laser precision is crazy, it’s sharp as a razor!

Roger Jungo

Roger Jungo

Technical characteristics

Dimensions

- Working area:

- 1600x1600 mm

- Installation type:

- Floor-standing

- Weight:

- 590 kg

- Machine size:

- 2260 x 2200 x 1662 mm

- Frame:

- Welded steel

Materials Table

- Materials:

- Wood, Soft Metal, Composite, Aluminium, Plexiglass, Plastic, Plywood, Paronite, Chipboard, MDF

Mechanics

- Dimension of the guides:

- 20 mm

- Idle speed:

- 15 000 mm/min

- Tool lifting height (Z-axis travel):

- 200 mm

- Positional accuracy:

- 0,05 mm

- Positional resolution:

- 0,00625 mm

- Engine power:

- 4A 5N.m

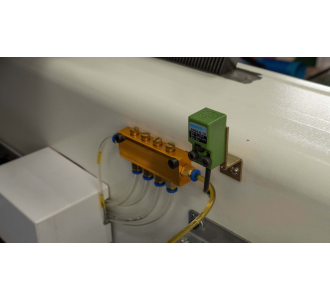

Hardware

- Power electrics:

- Siemens, Chint

- Motor drivers:

- Leadshine dma860H

- End sensors:

- Capacitive

- Electric power supply:

- 220/380 V

- Software:

- NcStudio

- File transfer:

- USB, DSUB

- Power consumption:

- 3900 W

Spindle

- Spindle:

- 3 kW

- Spindle RPM:

- 24 000 rpm

- Collet chuck:

- ER-20

General

- Rotary device (optional):

- Yes

- Lubrication system:

- Manual

- Number of axis movements:

- 3

- Bed type:

- Welded steel

Included kit

-

Wrench set

-

Clamp set

-

Milling bits set

-

Collet set

-

NC studio PCI-card

-

NC studio connection cable

-

Aspiration system adapter

-

Fuse kit

-

USB cable

-

Power cable

Not sure where to start?

Our managers are here to advise you