Virmer offers universal CNC laser machines for cutting and engraving suitable to address any challenge. We sell CNC laser machines created on the basis of components of world brands throughout Europe.

To learn more about CO2 laser machines please refer to the catalog or consult with Virmer managers +31208082045, info@virmer.com..

Operation principle of the cnc laser machine

A special flask (laser tube) filled with a mixture of gases, the main of which is CO2, generates the laser radiation The laser radiation is generated inside the energised laser tube.

A system of movable mirrors reflects and sends a laser beam to the working head with a focusing lens. The focused laser beam has a high power density, therefore, due to thermal influence, the beam is able to effectively cut through or engrave various materials.

A special program supplied with a CO2 laser machine controls the degree and method of exposure.

Please note that CO2 laser machines do not work with metals. For metal cutting please refer to the section with CNC metal cutting laser machines and for metal engraving equipment - to the section with laser marking machines.

What can you produce with a cnc laser machine

CO2 laser machines are used in the woodworking industry, design and advertising, in the souvenir industry, as well as the textile industry and other application fields. Such CNC laser machines allow you to produce:

- Souvenirs: jewelry boxes, magnets, award products, greeting cards, personalized products;

- Children products: toys, twisters, puzzles, constructors, busy boards;

- Advertising and POS products: badges, numbers, pointers, signs, three-dimensional letters, boxes, elements of showcases;

- Elements of interior and exterior design;

- Test patterns for the textile industry, as well as engraving on jeans and leather;

- Shoes: Cutting and perforating leather with a CO2 laser machine;

- Furniture: cutting plywood, veneer and upholstery materials;

- Matting and engraving of glass, stone and ceramics.

The application field of CO2 laser machines is limited only by your imagination and initiative.

Products created on CNC laser machines can be found everywhere. And that's why laser cutting and engraving has become so popular.

Advantages of CO2 laser machines.

CO2 laser machines have three main advantages:

- Multipurposeness CO2 laser machines work with a wide range of materials: wood, plywood, MDF, chipboard, acrylic, PET, foam rubber and other plastics and polymers, rubber, paronite, stone and ceramics, mirror and glass, cardboard, paper and various fabrics, fur and leather.

- Working speed depends on the density, type and thickness of the material. Very thin and light materials, such as fabrics, the CO2 laser machine will cut at a speed of up to 150 mm/s. The engraving speed of the CNC laser machine reaches 500 mm/s.

- Performance quality A special program which controls the main process reduces the risk of reject. At the same time, the positioning accuracy of the CNC laser machine reaches 0.03 mm, and the laser beam diameter is so small that it allows you to cut patterns of any complexity. The edge after cutting with CO2 laser machine is always smooth, and in respect to engraving process you can choose the exposure rate to adjust the contrast of the image.

The operating skills of a CO2 laser machine are quite easy to master, it does not require complex maintenance, additional consumables or replaceable tools.

Another advantage is that the CO2 laser machine is quite silent and dust-free — this makes working with it more pleasant compared to other types of material cutting equipment.

Criteria for choosing a CO2 laser machine

For a competent choice of a CO2 laser machine, it is advisable to decide what exactly you want to produce. This will allow you to figure out a required working field size and laser tube power of a CNC laser machine.

Working field size of the CO2 laser machine

This criterion determines the maximum size of the product, as well as frequency of material change on the working field.

CO2 laser machines types:

- Desktop machines (200x300 mm, 500x300 mm, 600x400 mm),

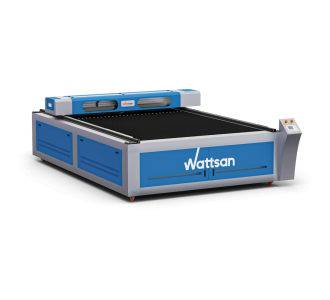

- Medium format machines (600x900 mm, 1200x900 mm),

- Large format machines (1600x1000mm, 2000x3000 mm).

Laser tube power of the CO2 laser machine

The laser tube power determines the maximum thickness of the material to be cut and the working speed of CO2 laser machine. For example, the following universal formula is suitable for cutting plywood on a CNC laser machine: 10W of power are sufficient to cut through about 1 mm of plywood. For other materials, the calculations will be slightly different.

It is logical that the more powerful the emitter of the CO2 laser machine, the faster it will cut through the material.

In addition to the above mentioned main characteristics, the CNC laser machine has many other features, for example:

- Working table. The working table of a CO2 laser machine can consist of lamellae or represent a honeycomb table. Lamellas are a universal type of working table, but they must be anodized in order to avoid shooting a laser beam on the material. A honeycomb table is used for cutting fabrics or products with many small details.

- Motors. The best solution for a CO2 laser machine is three-phase motors, as they have increased accuracy. Motor drivers also play an important role.

- The frame and body of the machine. The heavier the frame and body of the CO2 laser machine, the less it is subject to vibrations.

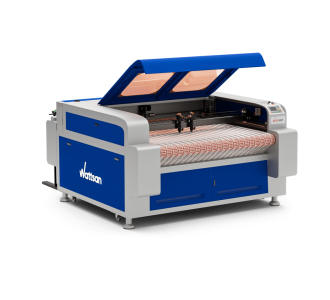

- Number of working heads. Some models of CO2 laser machines are equipped with two working heads, which speeds up the performance twice.

- Portal. It is one of the main elements of movement, and the laser head also moves along it. The portal should be designed for expected loads.

- Optical system. Includes reflective mirrors and a focusing lens. The optical system of the CO2 laser machine must be both reliable and convenient for regular adjustment, i.e. adjustment of the the machine optical path.

- Height-adjustable table. Some models of CO2 laser machines are equipped with a table lifting and lowering mechanism. This function may be necessary to work with thick materials or to install a rotating device.

- Rotating device. Allows you to engrave cylindrical products on a CNC laser machine, e.g. glasses.

- Waste collection chamber. It is necessary for operational comfort, in addition to its main function, this chamber additionally enhances the exhaustion rate of the CNC laser machine.

- Cooling system. The laser tube of the CNC laser machine requires cooling for protection against overheating and failure. By default, CO2 laser machines are equipped with a water pump, but Virmer engineers always recommend our customers to use a more reliable cooling system for CNC laser machine emitters — a chiller.

Conclusion

A CO2 laser machine is a complex system where all the elements are interconnected with each other and it can be difficult to understand all the nuances without experience.

For example, availability of gearboxes, the quality of belts and even the location of the motors can affect quality of the CNC laser machine. The result of cutting and engraving is influenced by both the lens and the laser head nozzle diameter as well as blowing force. And the safety of the entire system depends on the correct location of electrical components in the machine body — the wiring must be isolated from the water distribution system and located in different parts of the machine body.

To get a detailed consultation or to sign up for an online demonstration, please contact the managers of Virmer: +31208082045, info@virmer.com.