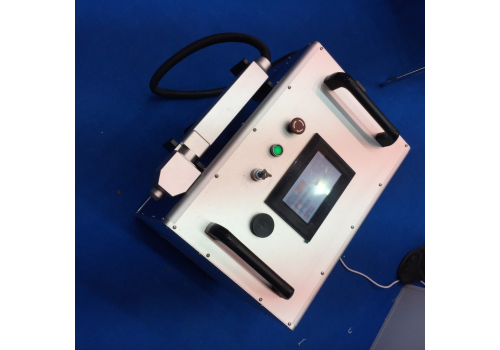

Laser surface cleaning machine Wattsan 100W

Brief of Laser Surface Cleaning Machine Wattsan 100W

Wattsan 100W hand-held laser cleaning machine allows for a mode to suit your application

The Wattsan 100W hand-held laser cleaning machine is a new generation of high-tech equipment for cleaning metal surfaces without damaging or thermally deforming the base material. Removes almost all types of contaminants on metal products: rust, paintwork, oil products, oxide films, scale after welding, and carbon deposits. Pulsed laser cleaning is designed for cleaning large areas. The main task is to remove the layer to be removed without damaging the base. This is especially true when cleaning thin metals, since the machine does not expose the base to heat and, as a result, deformation. A big plus is the speed at which the positive result is immediately visible. The equipment does not make noise during operation, and besides, everyone will cope with its use. In addition to metal surfaces, it cleans adhesive and galvanized materials, as well as products made of plaster and stone.

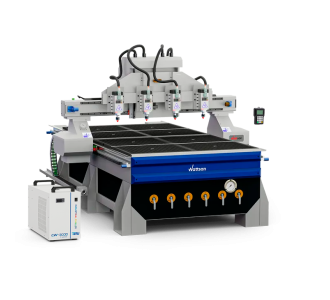

Perfect synergy: Relfar & RuiDa

Comparison table

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

|---|---|---|---|

| ≤25 | 15 | 100 | 5 |

| ≤50 | 7,5 | 100 | 2,5 |

| >50 | 7,5 | 60 | 1,5 |

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

| ≤50 | 15 | 60 | 3 |

| ≤100 | 10 | 60 | 2 |

| >100 | 5 | 60 | 1 |

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

| ≤50 | 10 | 30 | 1 |

| ≤100 | 5 | 30 | 0,5 |

| >100 | 2 | 30 | 0,2 |

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

| ≤25 | 10 | 60 | 2 |

| ≤50 | 10 | 30 | 1 |

| >50 | 8 | 20 | 0,6 |

The scanner is easy to operate and requires little maintenance.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

Technical characteristics

Included kit

Ask questions

-

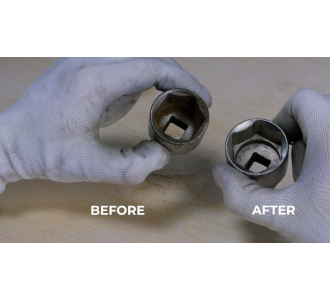

Laser cleaning removes corrosion, rust, paint-and-lacquer coatings, scale, carbon deposits, electroplating coatings, adhesive coatings, and organic deposits.

-

Compared to mechanical and chemical methods, this method is not traumatic – it does not imply human contact with the treated surface, and is environmentally friendly – there are no toxic vapors. The risk of damaging the metal from which you remove rust or paint is also eliminated.

-

There are a few basic parameters that affect the choice when buying the laser cleaning machine, namely: pulsed or continuous mode of radiation, power of laser head, type of cooling, laser cleaning functionality, and requirements to the supplier. First of all, it is necessary to decide which tasks will prevail – delicate cleaning or handling with gross contaminations and deposits. This determines which type of radiation to choose – pulsed or continuous.

-

The service life of the laser emitter is up to 100 000 hours, which is 30 years of continuous operation 8 hours a day, 5 days a week.

-

Laser cleaning machine performs its main functions fast and allows you to save time on dismantling. Therefore, laser cleaning is 6-8 times faster than chemical cleaning methods.