Catalog Laser Cutting Engraving Machines

Laser machines for Fabric

Virmer offers its customers a wide range CO2 laser machines and engravers.

Catalog of CO2 laser machines for cutting and engraving materials such as: plywood, MDF, veneer, wood, acrylic, polystyrene, PET, plastics, paronite, rubber, cardboard, paper, fabrics, fur, leather and leatherette.

-

Laser Engraving Machine 100W co2 WATTSAN 6040 Wattsan 6040

View productFrom 4 319 € ex.VAT

-

Laser Cutting Engraving Machine 100W CO2 WATTSAN 6090 ST Wattsan 6090 ST

View productFrom 4 976 € ex.VAT

-

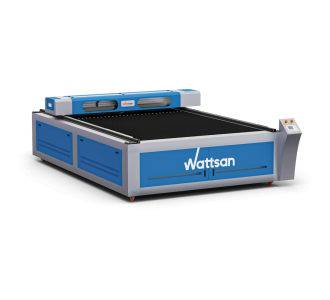

Laser Cutting Engraving Machine 100W co2 WATTSAN 1290 ST Wattsan 1290 ST

View productFrom 6 043 € ex.VAT

-

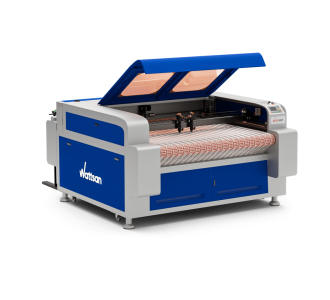

Laser Cutting Engraving Machine 130W co2 WATTSAN 1610 ST Wattsan 1610 ST

View productFrom 7 926 € ex.VAT

-

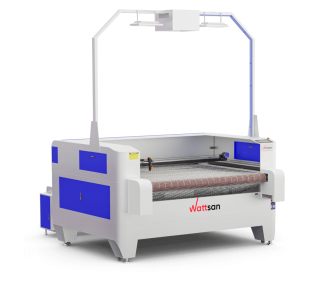

Laser Cutting Engraving Machine 130W co2 WATTSAN 1610 LT Wattsan 1610 LT

View productFrom 8 348 € ex.VAT