- Main

- Equipment catalog

- Laser CO2

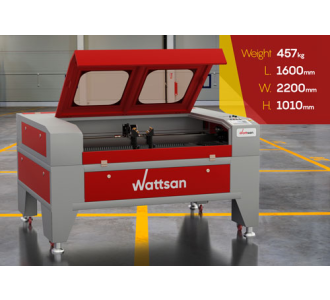

- WATTSAN 1610 DUOS LT

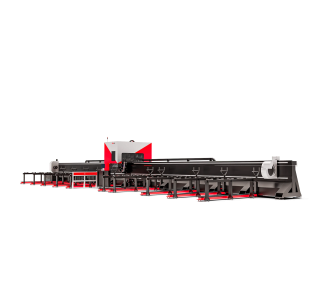

Laser machine WATTSAN 1610 DUOS LT In stock

- Working area:

- 1600x1000 mm

- Laser power:

- 100-130 W

- Working table lowering depth:

- 160 mm

- Positioning precision:

- 0,03 mm

- Machine size:

- 1600 x 2200 x 670 mm + if it is on wheels 315 mm

- Packing size:

- 2300 x 1750 x 810 mm

- Weight:

- 457 kg

Unique selling proposition

-

Ruida 6445G control system

-

2 laser heads

-

No vibrations

-

Framed structure

-

Lifelong support

Brief of Laser Cutting Engraving Machine 130W co2 WATTSAN 1610 DUOS LT

Wattsan 1610 Duos LT laser cutting machine — double your production!

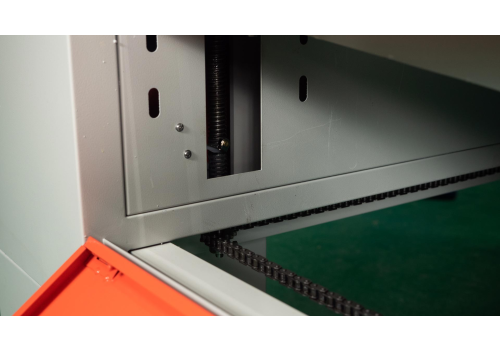

Co2 Laser Cutting Engraving Machine Wattsan 1610 Duos LT speeds up the mass production process by 2 times. Two laser heads work synchronously with a minimum distance of 130 mm from each other. Each head has a separate laser tube with 100-120 W, which makes it easy to work at the highest speeds. The working table is equipped with a chain that allows you to lower and raise the table when engraving on super-heavy items up to 80 kg such as stone. The laser machine can easily handle wood, plywood, cardboard, paper, plexiglass, acrylic, plastic, rubber, leather, fabrics and fur.

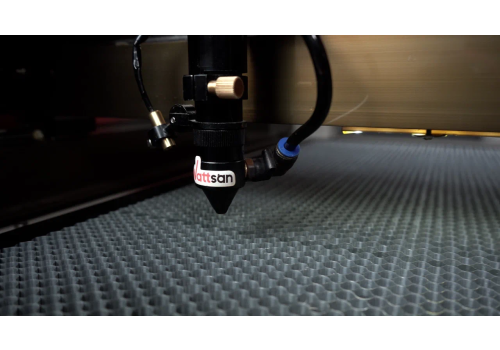

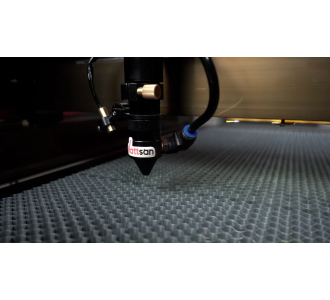

The reduced area nozzle guarantees the cleanest cut on all types of materials, especially plywood and leather, avoiding secondary processing of the material.

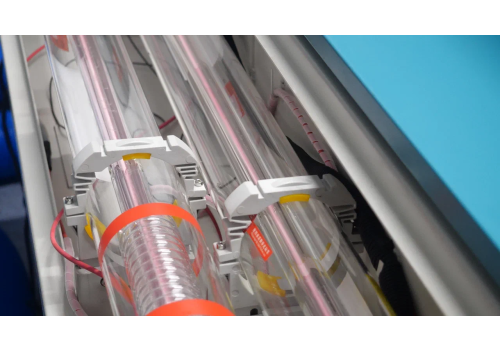

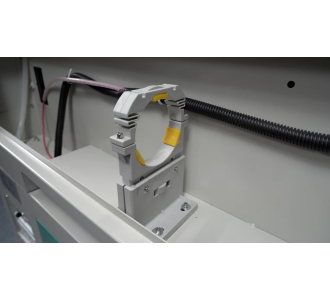

Universal mounts for the laser tube allow for the quick replacement, regardless of the diameter or power of the tube.

Materials

-

– cutting

-

– engraving

-

Wool

-

Resin

-

Marble

-

Granite

-

Bamboo products

-

Crystale jade

-

Ceramic tile

-

Paronite

-

Stone

-

Glass

-

MDF

-

Foam rubber

-

Polyethylene foam

-

Plexiglass (Acrylic)

-

Fabric

-

Leather

-

Rubber

-

Plastic

-

Cardboard

-

Plywood

-

Wood

Wattsan laser machines are thoughtfully designed

-

Increased thickness of housing

The stiffness of the machine is ensured not only by the frame but also by the thickness of the housing, which is especially important for large models. The long service life of the machines is also due to the thickness of the machine body.

-

Frame structure

The main feature and base of Wattsan machines is a frame structure. The frame design ensures vibration-free operation at high speeds during engraving. This makes the machines less likely to require maintenance. Machine frames are continually being improved to increase the rigidity of Wattsan machines.

-

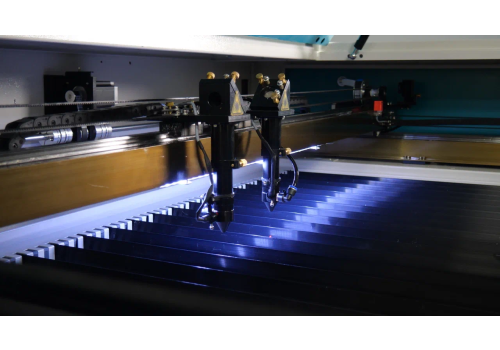

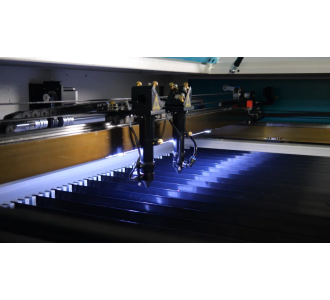

2 laser heads

The parallel operation of two laser heads allows you to double the productivity of the machine, which is quite useful for processing fabrics and producing souvenirs, puzzles, etc. The laser heads can divide the working field in half (for cutting or engraving large items) or work in close proximity to each other. A single laser head can also be used for the production of particularly large items.

ST & LT: what's the difference?

-

ST model

Equipped with a static table, suitable for processing flat materials of consistent thickness. This setup is ideal for standard cutting and engraving tasks where material height remains uniform.

- Fixed

- Height Adjustability

- No

- Supports Rotary Device

- Limited

- Versatility

- Flat sheets and repetitive work

- Application

-

LT model

Features a lift table that can be adjusted vertically, accommodating materials of varying thicknesses and enabling rotary device usage for cylindrical objects. This design offers greater versatility for diverse applications.

- Adjustable

- Height Adjustability

- Yes

- Supports Rotary Device

- High

- Versatility

- Varied work, 3D objects, custom jobs

- Application

Wattsan - designed and engineered for business owners

-

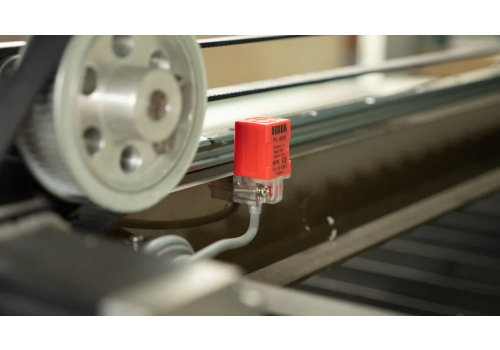

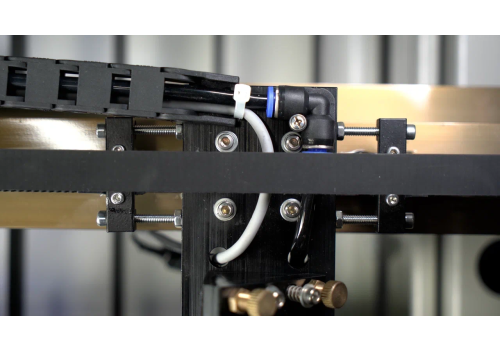

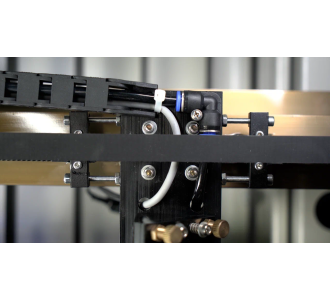

Upgraded blowing system up to 8 atm

The maximum working air pressure for blowing is 6 atmospheres and up to 8 atmospheres for bursting. This is possible due to the well-arranged connectors and polyurethane pipes. High pressure is required when cutting thick materials or a clean cut edge is required.

-

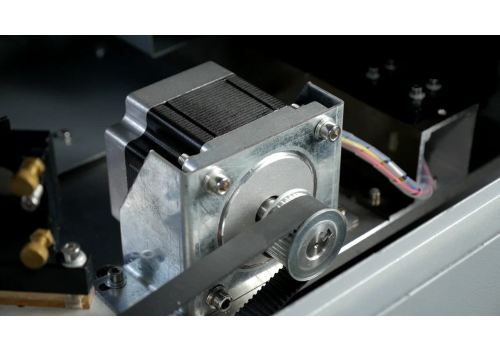

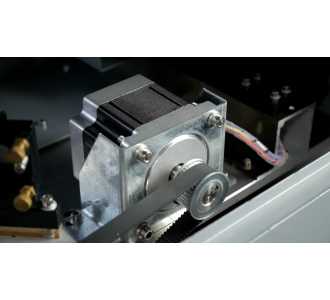

3-phase stepper motor

A 3-phase stepper motor is more accurate than a 2-phase stepper motor and has increased reliability and longer service life.

-

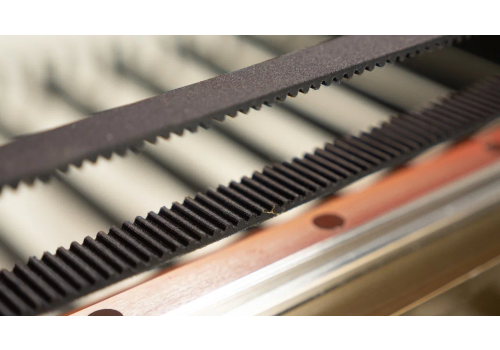

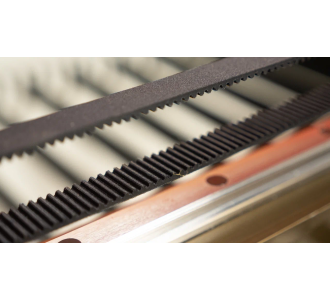

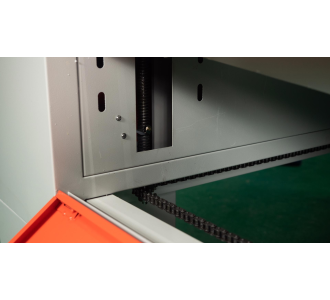

3M belt

Even under high tension, 3M belts do not flap and prevent uneven cutting, and the enlarged tooth is free from wearing-off and lasts several times longer than conventional belts.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

-

This laser engraver can engrave without any problem. How fast and easy it is able to customize products!

Riccardo Muscarella

Riccardo Muscarella

-

Machine has a perfectly flat surface. It makes repetitive work easier for me!

Matteo Moras

Matteo Moras

-

Great job done within an hour. Thanks to the speed of the laser CO2 machine.

Roberto D'Adago

Roberto D'Adago

-

This model is great, and laser precision is crazy, it’s sharp as a razor!

Roger Jungo

Roger Jungo

Technical characteristics

Dimensions

- Working area:

- 1600x1000 mm

- Packing size:

- 2300 x 1750 x 810 mm

- Through table:

- Yes

- Working table lowering depth:

- 160 mm

- Weight:

- 457 kg

- Machine size:

- 1600 x 2200 x 670 mm + if it is on wheels 315 mm

Materials Table

- Materials:

- Leather and leatherette, Rubber, Wood, Plexiglas, Plastic, Paper, Fabric, Paronite, Stone, Plywood, Acrylic, Cardboard, Denim, MDF and chipboard

Optics

- ZnSe lens:

- D20 F50.8

- Diameter of mirrors:

- 25 mm

- Laser tube:

- Reci W4

- Focal length:

- 50 mm

- Laser type:

- Sealed CO2 laser tube

- Positioning precision:

- 0,03 mm

- Min. letter size for engraving:

- 1,5x1,5 mm

- Laser power:

- 100-130 W

- Laser tube lifetime:

- 10000 h

- Max. cutting thickness (wood):

- 10-13 mm

Mechanics

- Cooling:

- Water

- Automatic working table lift:

- Yes

- Second laser head:

- Yes

- Engraving speed:

- 0-600 mm/s

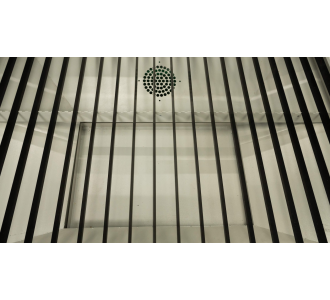

- Table model:

- Lamels

- Cutting speed:

- 0-400 mm/s

- X-Y axis structure:

- Linear guide AMT PMI MSB 15S

- Engine on X and Y:

- Stepper motors (three-phase)

Hardware

- Software:

- RD Works

- Control system:

- Ruida RDC 6445G

- File transfer:

- USB, LAN

- Supported format:

- WMF, SKA, WBMP, TIFF, TGA, ICO, JBG, CUR, PGX, PNT, AI, MNG, DXF, PLT, JPC, PNG, BMP, DWG, GIF, RAS, EMF, JPEG, JPG, PNM, PCX, PDF, DST, RAW, TIF, DSB

- Power consumption:

- 3400 W

- Electric power supply:

- 220 V

Included kit

-

USB flash drive

-

Hex wrench set

-

Manual

-

Air compressor

-

Water pump

-

Ethernet cable

-

Power cable

-

USB cable

-

Silicone sealent

-

Masking tape

-

Hose barb

-

Silicon tube set

Not sure where to start?

Our managers are here to advise you

Frequently Asked Questions

-

First of all you should decide what are you going to use the machine for, what kind of material would it be and it's size (length and thickness). This will help determine the required power of the laser tube as well as the size of the working area. You can also write or call us, we will be happy to help you choose the right machine for your tasks and budget

-

Laser engraving machine is a piece of computer numerical control (CNC) equipment that uses a laser beam to engrave necessary graphic information (image or inscriptions) on various surfaces.

-

Engraving is the effect on the material in depth. Marking on the other hand only changes the color of the material.

-

Using CO2 laser machine you can engrave any type of wood materials: solid wood, plywood, MDF and others.