Laser marker WATTSAN 1530 CABINE

-(1).png)

Brief of Fiber metal cutting machine WATTSAN 1530 CABINE

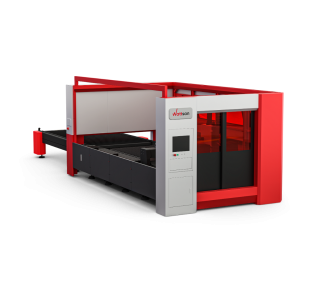

WATTSAN 1530 CABINE is a powerful professional metal cutting machine. The machine uses in the processing of stainless and carbon steel, copper, aluminum, galvanized plates and other metals. This machine is equipped with a special cabin that creates the safe conditions necessary for working with high power. The machine is used in mechanical engineering, aerospace, advertising industry, in the production of elevators and locomotives, for the manufacture of electrical equipment and spare parts.

WATTSAN 1530 CABINE machine is equipped with a choice of one of the high-power, precise and high-speed emitters: MAX / Raycus / IPG. One of the main advantages of this laser is the long service life of the ignition unit, which is 100,000 hours. It is possible to install lasers of various power on this machine: 1500/2000/3000/4000/5000 Watts.

Cypcut control system is responsible for the operation of the machine. Servo motors move the portal along the X, Y, Z axes. The machine is equipped with wear-resistant Hiwin guides. The industrial chiller provides timely cooling of the mechanism and will not allow annoying breakage or combustion. It comes with the machine.

WATTSAN 1530 CABINE is an advanced high power machine with many features that provide high precision and cutting speed. It is durable: the service life of the bed reaches 20 years, and the service life of the ignition unit is 10 years of intensive work. And the protective cabin makes the operator's work comfortable and absolutely safe.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

Technical characteristics

Ask questions

-

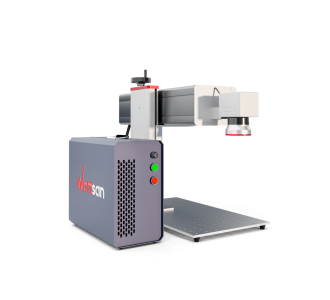

Laser markers usually have small working area: from 100*100 to 300*300. You should keep it in mind while choosing the machine.Then you should decide what type of material are you going to work with. For exaple Co2 marker is good for wood, plastic and plexiglass. If you want to mark metal then you should pick fiber laser marker. The choice of emitter depends on the desired result. For example, if you want to do color marking on metal, then IPG or JPT are an excellent choice.

-

It is a permanent image resistant to mechanical damage, acidic and alkaline media, high and low temperatures.

-

It depends on your application. The main selection criterion is the emitter power and the lens. For quick deep engraving or working on highly reflective metals, it is better to use emitters with a power of 50W and a lens with a working area of 110x100mm. For high quality marking a 20-30W emitter and a 200x200 or 300x300 mm lens will do the trick. For more details, please contact Virmer managers: +31208082045, е-mail: info@virmer.com

-

For the hobby, budget markers with MaxPhotonics or Raycus emitters are suitable. However, if your hobby is jewellery making, you should consider machines with IPG emitters from 50W. For more details, please contact Virmer managers: +31208082045,

е-mail: info@virmer.com -

CO2 laser sources mark and engrave organic materials: plywood and all types of wood-based materials, paper and cardboard, leather and faux leather, fabric, glass and mirror, plastics and rubber, stone and ceramics. Fiber emitters mark and engrave metals (ferrous metals, stainless steel, aluminium, titanium, etc), plastics and rubber, leather and faux leather.