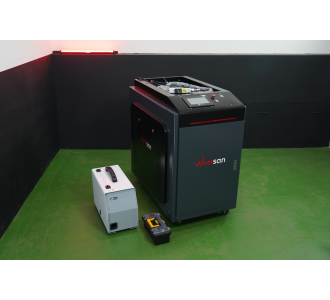

Handheld laser welding machine Wattsan Welding 3-in-1 Х2000 Raycus

Brief of Handheld laser welding machine Wattsan Welding 3-in-1 Х2000 Raycus

Multifunctional welding machine — 3 in 1: welding, cleaning, cutting and weld cleaning

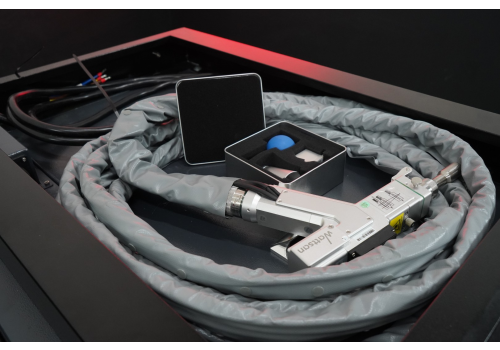

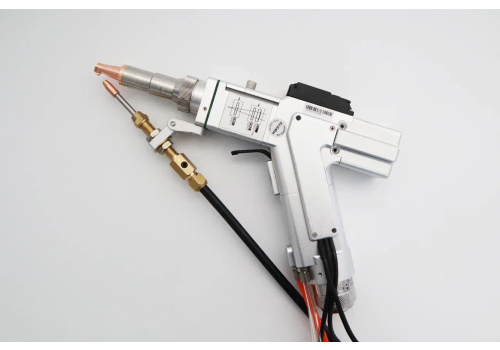

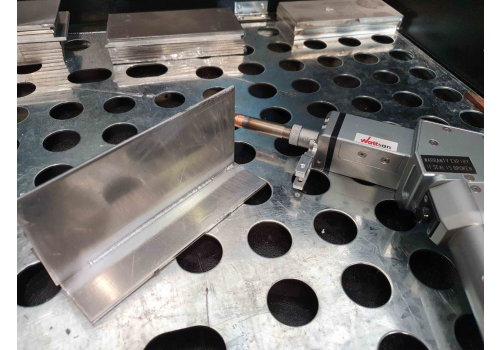

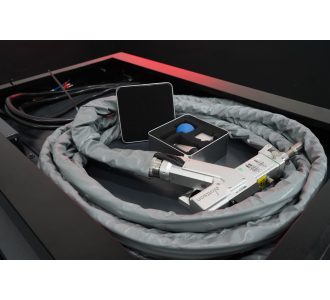

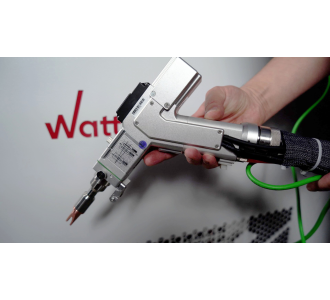

The Wattsan X 3 in 1 manual laser welding system is fitted with a universal laser head capable of cleaning, cutting and welding metal. This offers substantial saving by purchasing one machine instead of three. A library of loaded modes for joining various metals with a 0.3 to 7-mm thickness simplify the welding process. Laser welding technology allows welding metals such as carbon steel, galvanized stainless steel, as well as alloys of aluminum, brass and titanium, etc. The kit includes a specific nozzle for each type of task such as cleaning metals, butt welding, welding internal and external corners of welding with wire feed, cutting thin sheet metal, etc. The welding module can be easily replaced with a cleaning scanner, without reconnecting the welding gun and optical fiber. Easy to use, no specific skills required.

Mirror Technology: Customized for Your Project

Materials

|

||||

| Material | Set the power | Speed (mm/sec) | Frequency (kHz) | |

|---|---|---|---|---|

| 1 mm | 260 watts | 800 | 5 | |

| 1.5 mm | 340 watts | 750 | 5 | |

| 2 mm | 600 watts | 800 | 5 | |

| 2.5 mm | 730 watts | 700 | 5 | |

| 3 mm | 860 watts | 720 | 5 | |

|

||||

| Material | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 480 watts | 700 | 20 | |

| 1.5 mm | 560 watts | 800 | 20 | |

| 2 mm | 780 watts | 800 | 20 | |

| 2.5 mm | 920 watts | 800 | 20 | |

| 3 mm | 1150 watts | 800 | 20 | |

|

||||

| Material | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 900 watts | 600 | 30 | |

| 1.5 mm | 1100 watts | 600 | 30 | |

| 2 mm | 1350 watts | 500 | 30 | |

| 2.5 mm | 1600 watts | 500 | 30 | |

| 3 mm | 1850 watts | 500 | 30 | |

|

||||

| Material | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 650 watts | 600 | 30 | |

| 1.5 mm | 850 watts | 600 | 30 | |

| 2 mm | 1100 watts | 500 | 30 | |

| 2.5 mm | 1400 watts | 500 | 30 | |

|

||||

| Material | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 300 watts | 500 | 20 | |

| 1.5 mm | 370 watts | 500 | 20 | |

| 2 mm | 480 watts | 600 | 20 | |

| 2.5 mm | 600 watts | 600 | 20 | |

| 3 mm | 760 watts | 700 | 20 | |

|

||||

| Material | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 320 watts | 600 | 20 | |

| 1.5 mm | 460 watts | 600 | 20 | |

| 2 mm | 600 watts | 500 | 20 | |

| 2.5 mm | 800 watts | 700 | 20 | |

| 3 mm | 960 watts | 650 | 20 | |

Working in uncomfortable positions – gun weighing only 1 kg

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

Technical characteristics

Ask questions

-

The machines requires the minimum amount of consumables: nitrogen/argon and electricity, consumable electrodes are not required. Parts are welded without using a filler wire although it can be fed as an option.

-

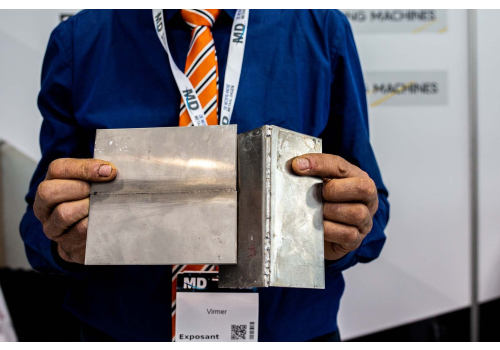

The working surface does not need cleaning or polishing before and after welding. The surface cleanness is not so essential for laser welding as for MIG welding.

-

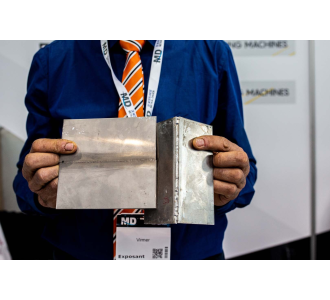

The laser welding machine suits for butt welds, fillet welds, T-welds, circumferential welds, ill-fitting items. The welding process results in a high-quality weld free from distortions and burn-through that does not require postweld treatment (due to a limited heat-affected zone).

-

The laser welding machine is able to weld: carbon steel, low-alloy steel, high-strength constructional alloys, stainless steels, aluminium, copper and brass alloys, titanium, plastics, dissimilar materials. Quick adjustment for a new material is available. Laser welding is easily integrated in a manufacturing process.

-

Laser welding is much more fire-safe as compared to traditional welding processes, no molten metal and hazardous sparks are ejected during welding. This makes labour conditions more comfortable.