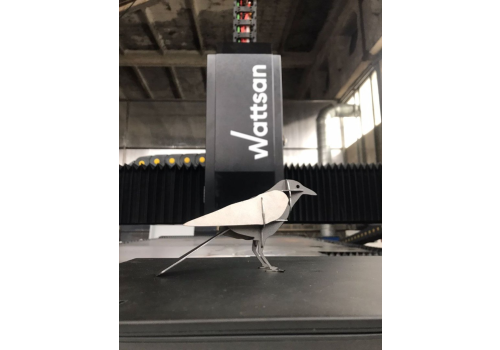

Fiber metal cutting machine WATTSAN 1325 E

Unique selling proposition

-

Extensive upgrade options

-

Guide rail protection

-

Eficient smoke extraction

-

Framed structure

-

3 years warranty on the emitter

Brief of Fiber metal cutting machine WATTSAN 1325 E

Laser machine Wattsan 1325 E — guaranteed precise accuracy

The WATTSAN 1325 E laser machine is a functional machine for cutting metal up to 3-4 mm thick. The machine works with stainless and carbon steel, copper, aluminum, titanium and other materials.

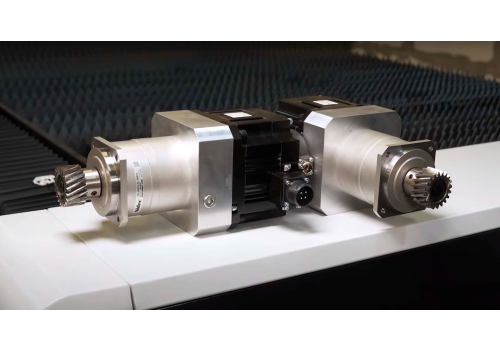

The working field of the machine is 1300x2500 mm. The machine is controlled by the Cypcut control system, which allows you to determine the positioning point with an accuracy of ± 0.02 mm. Precise and reliable Mitsubishi servomotors are responsible for the movement along the X, Y and Z axes, providing acceleration up to 1.5 G, which gives high material processing speed. An industrial cooler for timely cooling is included in delivery kit and protects the mechanism from failure.

Equipped with a high-quality fiber-optic emitter with a guaranteed long service life.

The WATTSAN 1325 E laser metal cutting machine is used in aircraft and mechanical engineering, in the production of electrical equipment, auto parts, advertising products, etc.

Adjust the cutting process for your production

CYPCUT software has simple user-oriented controls. The implemented functions greatly simplify and optimize the cutting process.

Metal cutters from Wattsan — forget about repairs and downtime

-

Precise design

In the process of designing the machine, various tests of static and dynamic loads were carried out to identify the maximum permissible deformations of the table and the bed in order to preserve the correct geometry of the structure. Due to the selected configuration, the maximum load on the table is increased by 800 kg of distributed weight. This allows processing materials up to 15 mm thick, with a 24/7 cutting accuracy of +-0.01 mm ,and ensures the durability of the bed up to 10 years.

-

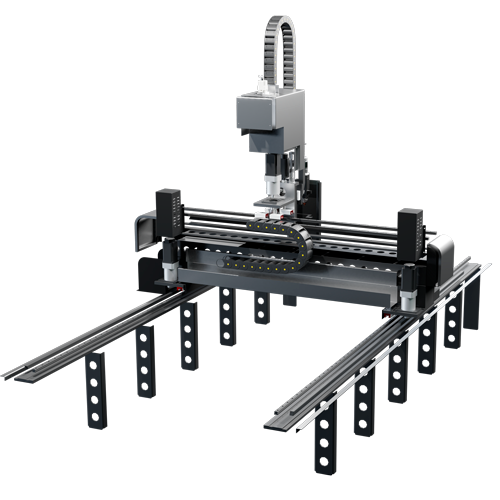

Frame type for your tasks

Thanks to the aluminum portal and the design precisely calculated by our engineers, the machine is completely insured against deformations and breakdowns. Depending on your tasks, Wattsan machines use portals of three types: 3rd generation aluminum portal, lightweight aluminum portal of ZL101A and GB/T17 standard, and aluminum portal with titanium for operation at speeds over 120 m/min.

-

Rigidity and stability

The E series machines have a frame with a cross-section of 6-8 mm, which allows cutting metal up to 8 mm thick. Wattsan frames have state-of-the-art design with the main task to avoid vibration when working at design speeds and accelerations. The frame can be installed on vibration mounts or anchored to a 50 cm thick concrete cushion.

-

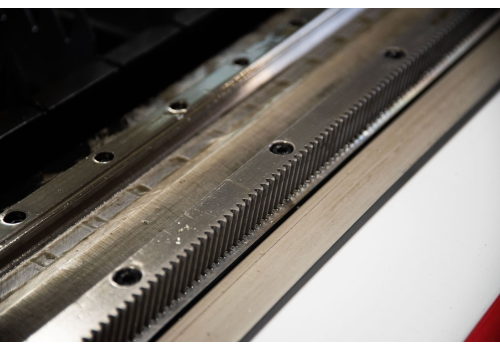

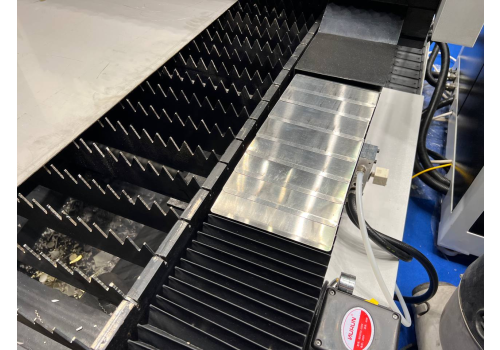

Double protection of the guides

Wattsan machines are equipped with a special metal protection of the machine corrugated surface to further maintain the cleanliness of the sliding guides, saving time and money for replacing the dust cover.

-

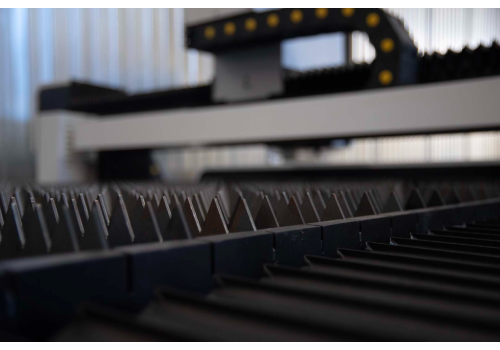

Loading rollers

Several ball bearings on the working table make it easier the sheet loading onto the table. The rollers can be mounted on the front, back or side of the machine as desired. The roller is lifted above the cutting table in such a way as to ensure optimal feeding. One of the most important advantages of this feeding system is the prevention of scratches on the material.

Firm frame structure of Wattsan machines

During the machine operation inertia of gentry motion is transferred to the frame which is subjected to significant loads. Therefore material and structure of the machine play a significant role in securing the machine against deformation and breakage.

-

In the process of designing the machine, all kinds of tests of static and dynamic loads were carried out to identify the maximum allowable deformations of the table and machine bed in order to maintain the correct geometry of the structure. Due to the selected design configuration, the maximum load on the table is increased by 800 kg of distributed weight. This allows you to process materials up to 15 mm thick, with a cut quality of +-0.01 mm and 24/7 and ensures the durability of the bed up to 10 years.

-

Wattsan frames are designed according to the latest technology, their primary objective is to avoid vibration when operating at design speeds and accelerations. The frame is installed on vibration mounts or is anchored to a 50 cm thick concrete pad.

-

All frames undergo multi-stage heat treatment within a day which results in less vibration during machine operation. This technology allows to release tension from metal and increase the machine’s service life from 10 years and more.

The machine frame is the base

Comparison table

|

||||

| Source power | 1000 W | 1500 W | 3000 W | 6000 W |

|---|---|---|---|---|

| Thickness, mm | Speed (m/min) | |||

| 1 | 10 | 22 | 34 | 42 |

| 2 | 6,2 | 6,8 | 7,5 | 8,2 |

| 3 | 3 | 3,6 | 4,4 | 5,5 |

| 4 | 2,2 | 2,8 | 3,8 | 5 |

| 5 | 1,8 | 2,4 | 3,2 | 3,6 |

| 6 | 1,6 | 2 | 2,6 | 3,4 |

| 8 | 1,2 | 1,4 | 2,2 | 3 |

| 10 | 0,8 | 1 | 1,6 | 2,4 |

| 12 | 0,8 | 1,4 | 2 | |

| 14 | 0,6 | 1 | 1,3 | |

| 16 | 0,8 | 1,1 | ||

| 18 | 0,7 | 1 | ||

| 20 | 0,6 | 0,9 | ||

| 22 | 0,5 | 0,8 | ||

| 24 | 0,6 | |||

| 24 | 0,4 | |||

|

||||

| Source power | 1000 W | 1500 W | 3000 W | 6000 W |

| Thickness, mm | Speed (m/min) | |||

| 1 | 23,8 | 26,4 | 34 | 41,4 |

| 2 | 10,8 | 11,9 | 15,4 | 28,6 |

| 3 | 2,3 | 4,1 | 8,6 | 15,8 |

| 4 | 1,3 | 2,2 | 5,5 | 9,4 |

| 5 | 0,7 | 1,2 | 4,3 | 6 |

| 6 | 1 | 3,1 | 4,7 | |

| 8 | 2 | 3,3 | ||

| 10 | 0,8 | 1,3 | ||

| 12 | 0,5 | 1,3 | ||

| 14 | 0,8 | |||

| 16 | 0,6 | |||

|

||||

| Source power | 1000 W | 1500 W | 3000 W | 6000 W |

| Thickness, mm | Speed (m/min) | |||

| 1 | 8,4 | 16 | 34 | 42 |

| 2 | 3,4 | 6,6 | 15 | 25,5 |

| 3 | 1,4 | 3,8 | 7,6 | 14,6 |

| 4 | 1,4 | 4 | 5,8 | |

| 5 | 3,3 | 4,9 | ||

| 6 | 2,1 | 4,1 | ||

| 8 | 0,9 | 2 | ||

| 10 | 0,6 | 1,7 | ||

| 12 | 0,8 | |||

| 14 | 0,6 | |||

| 16 | 0,5 | |||

|

||||

| Source power | 1000 W | 1500 W | 3000 W | 6000 W |

| Thickness, mm | Speed (m/min) | |||

| 1 | 8 | 12 | 22 | 32 |

| 2 | 3,2 | 4 | 8 | 12 |

| 3 | 1 | 2,2 | 5,2 | 6,4 |

| 4 | 1,4 | 4 | 5,4 | |

| 5 | 1,8 | 3,2 | ||

| 6 | 1,4 | 2,2 | ||

| 8 | 0,6 | 1,2 | ||

| 10 | 0,6 | |||

| 12 | 0,4 | |||

|

||||

| Source power | 1000 W | 1500 W | 3000 W | 6000 W |

| Thickness, mm | Speed (m/min) | |||

| 1 | 7 | 10 | 22 | 35 |

| 2 | 2 | 4 | 12 | 20 |

| 3 | 0,5 | 1,8 | 5 | 12 |

| 4 | 1 | 3 | 9 | |

| 5 | 2 | 6,5 | ||

| 6 | 1,3 | 3,8 | ||

| 8 | 0,6 | 1,8 | ||

| 10 | 1 | |||

| 12 | 0,7 | |||

High-tech equipment and verified accuracy are guaranteed

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

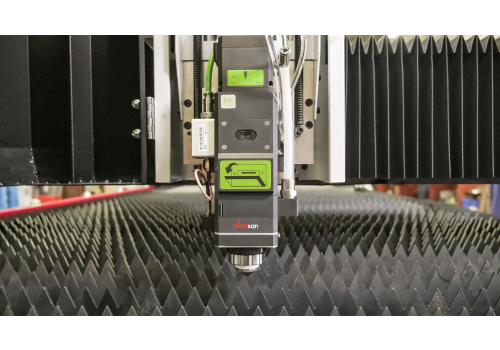

Laser head for your tasks

Wattsan metal cutters are equipped with laser heads from popular manufacturers such as Raytools, BOCI and Precitec.

Experiences from enthusiastic bloggers

Technical characteristics

Ask questions

-

A fiber-optic laser is best suited for cutting metal, but a specially equipped CO2 laser with a high-power laser tube may also be suitable for this purpose. However, it should be borne in mind that the thickness of the metal for cutting with a CO2 laser is limited to 1.5 mm, while a fiber-optic laser is capable of cutting up to 25 mm.

-

The cost of an hour of laser cutting depends not only on the power of the laser machine and the speed of its operation, but also on a number of other factors, such as: the professional skills of the machine operator, the cost of renting a production room, the cost and consumption of electricity, the cost of the material itself, the amount of scrap and downtime of the machine, and much more. In order to unambiguously answer the question about the cost of an hour of laser cutting, it is necessary to take into account all these parameters.

-

A focused laser beam is applied to the metal surface, as a result of which it melts, the molten material is blown out of the cutting zone with the help of an auxiliary gas.

-

The power of the laser emitter depends on the thickness of the material being processed and the desired processing speed. For example, a 1 kW emitter will cut 1 mm thick stainless steel at a speed of 13 m/min, and a 3 kW emitter will cut the same material at a speed of about 35 m/min. Here everything depends on the budget and the expediency of using the maximum possible capacity. Although it can be said that in today's competitive realities it does not make sense to buy a laser machine with a power of less than 1 kW.