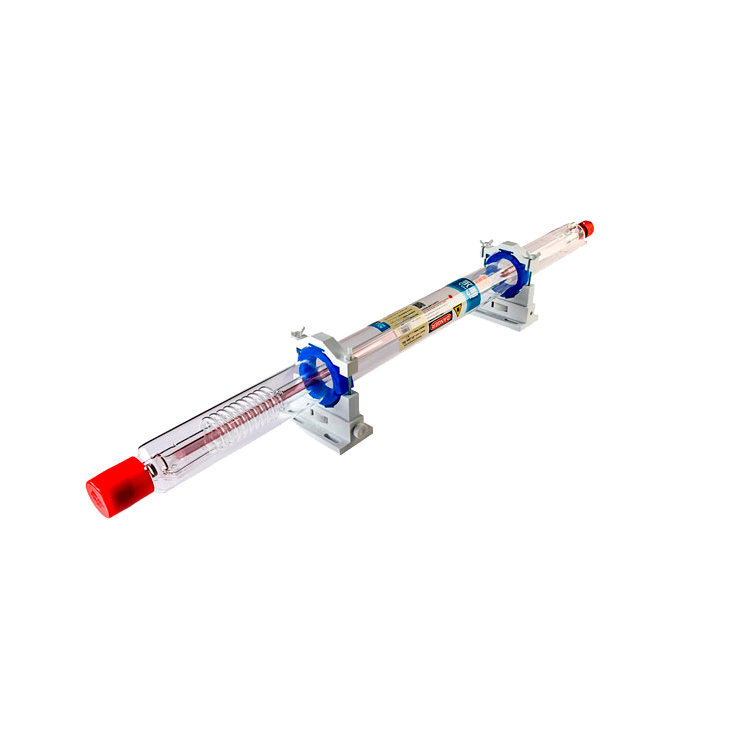

Laser tube Yongli R3 80-90W

Brief of Laser tube for CO2 Laser Machines Yongli R3 80-90W

Laser tube Yongli R3 is a reliable and durable device for high-precision processing of non-metallic raw materials. This model is installed in machines for precision cutting, engraving and marking of sheet materials. R3 tube provides stable and powerful laser flow (up to 90 Watts). Therefore, it is actively used in woodworking, light industry, advertising and many other areas where quality and intensive work process are important.

Materials for Yongli R3

Despite the fact that the R3 tube does not work on metal surfaces (it is required to use a special thermocouple, which significantly slows down the production cycle). The list of materials for Yongli R3:

- wood and materials based on it (plywood, MDF, CPD, veneer);

- plastic (plexiglass, PET, etc.);

- synthetic and natural fabrics;

- paper (any density and thickness);

- cardboard (simple, decorative, corrugated);

- leather, fur;

- marble, ceramics;

- ferronite, paronite, mica;

- polyfoam, foam rubber, rubber, etc.

Distinctive features of the Yongli R3 laser tube:

- gas discharge principle of laser flow formation. The working medium is a three-component gas mixture (CO2, N2, He). The high voltage ignition unit is a source of electric pulses;

- the body of the device is made of strong glass (the flask is imported from Germany);

- the tube is equipped with a built-in water cooling system with a liquid circulation rate of 2-5 l/s on average;

- there is an internal catalyzing sputtering of silver. This increases the life of the tube, accelerates the movement of laser particles, ensures the stability of emitting and enhances the flow power;

- the tube is universal and can be installed in any Chinese-made laser machine with suitable size of the tube bed;

- possibility of adjustment of internal optics power;

- competent and careful handling can extend the operational period to 7500 hours.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.