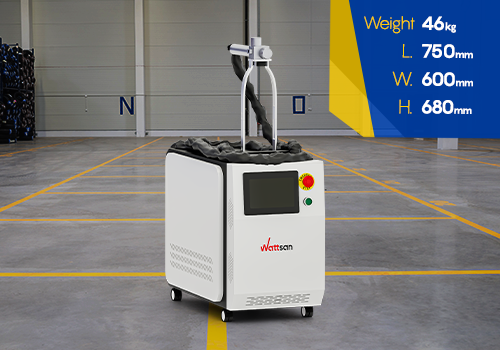

Laser surface cleaning machine Wattsan PA

Brief of Laser Cleaning Machine Wattsan PA

Handheld Laser Cleaning Machine Wattsan PA: Powerful Solution for Efficient Rust, Paint, and Coating Removal

The Wattsan handheld laser device is engineered for portable pulse cleaning, effectively removing both light and heavy contaminants from organic and inorganic surfaces without damaging the underlying material. It can clean not only metals but also items with adhesive and galvanized coatings, as well as materials like gypsum and stone. Its compact and lightweight design makes it easy to carry around, allowing you to move effortlessly throughout a facility or from one object to the next.

Cleaning patterns

Switch quickly between beam patterns for the desired result. Cover the required area without unneccesery overheating of the material:

Comparison table

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

|---|---|---|---|

| ≤25 | 25 | 140 | 12 |

| ≤50 | 25 | 70 | 6 |

| >50 | 20 | 60 | 4 |

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

| ≤50 | 20 | 100 | 8 |

| ≤100 | 20 | 50 | 4 |

| >100 | 10 | 50 | 2 |

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

| ≤50 | 15 | 50 | 2,5 |

| ≤100 | 8 | 40 | 1,2 |

| >100 | 5 | 35 | 0,6 |

|

|||

| Cleaning thickness (Nm) | Cleaning speed (mm/s) | Cleaning line width (mm) | Performance (m2/h) |

| ≤25 | 15 | 60 | 3 |

| ≤50 | 15 | 30 | 1,5 |

| >50 | 10 | 20 | 1 |

The scanner is easy to operate and requires little maintenance.

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

Technical characteristics

Included kit

Ask questions

-

Laser cleaning removes corrosion, rust, paint-and-lacquer coatings, scale, carbon deposits, electroplating coatings, adhesive coatings, and organic deposits.

-

Compared to mechanical and chemical methods, this method is not traumatic – it does not imply human contact with the treated surface, and is environmentally friendly – there are no toxic vapors. The risk of damaging the metal from which you remove rust or paint is also eliminated.

-

There are a few basic parameters that affect the choice when buying the laser cleaning machine, namely: pulsed or continuous mode of radiation, power of laser head, type of cooling, laser cleaning functionality, and requirements to the supplier. First of all, it is necessary to decide which tasks will prevail – delicate cleaning or handling with gross contaminations and deposits. This determines which type of radiation to choose – pulsed or continuous.

-

The service life of the laser emitter is up to 100 000 hours, which is 30 years of continuous operation 8 hours a day, 5 days a week.

-

Laser cleaning machine performs its main functions fast and allows you to save time on dismantling. Therefore, laser cleaning is 6-8 times faster than chemical cleaning methods.