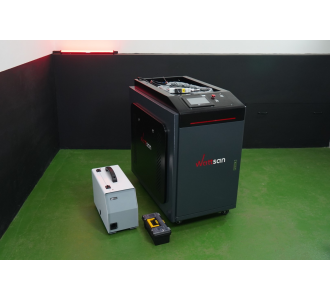

Brief of Handheld laser welding machine Wattsan 4in1 G2 JPT

Wattsan 4in1 G2 JPT laser welding welds product parts in any position

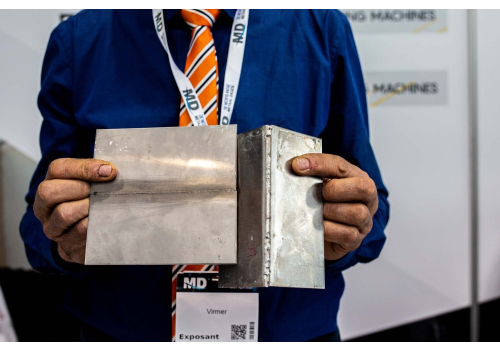

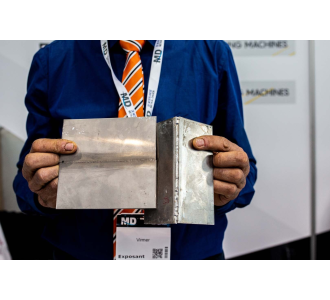

The Wattsan 4in1 G2 JPT hand-held laser welding machine provides high working speeds and perfect weld quality. It is used for joining various metals with a thickness of 0.3 to 7mm. The machine is capable of welding carbon, low-alloy, high-tension, stainless steel, aluminium and titanium alloys, plastics, and various dissimilar materials. It simplifies the welding of workpieces, even with a low qualification of the operator.

Different types of welding joints are available: butt joint, lap joint, tee joint, edge joint, and corner joint. The hand-held laser welding machine is used without filler wire, but if necessary, any wire feeding device can be integrated. The main consumables are working gas (nitrogen/argon), nozzles, and protection mirrors. Thanks to the 8 m cable, welding can be carried out over a considerable distance from the machine.

Select the type of seam for your welding tasks!

Before starting work, it is important to determine the type of weld, whether it be a butt joint, fillet weld, tee weld, lap weld and end joint. This will help you opt for the best welding technique in each case:

Mirror Technology: Customized for Your Project

Materials

|

|||||

| Material | Peak laser power | Set the power | Speed (mm/sec) | Frequency (kHz) | |

|---|---|---|---|---|---|

| 1 mm | 500 watts | 260 watts | 800 | 5 | |

| 1.5 mm | 500 watts | 340 watts | 750 | 5 | |

| 2 mm | 1000 watts | 600 watts | 800 | 5 | |

| 2.5 mm | 1000 watts | 730 watts | 700 | 5 | |

| 3 mm | 1000 watts | 860 watts | 720 | 5 | |

|

|||||

| Material | Peak laser power | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 500 watts | 480 watts | 700 | 20 | |

| 1.5 mm | 1000 watts | 560 watts | 800 | 20 | |

| 2 mm | 1000 watts | 780 watts | 800 | 20 | |

| 2.5 mm | 1000 watts | 928 watts | 800 | 20 | |

| 3 mm | 1500 watts | 1150 watts | 800 | 20 | |

|

|||||

| Material | Peak laser power | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 1000 watts | 900 watts | 600 | 30 | |

| 1.5 mm | 1500 watts | 1100 watts | 600 | 30 | |

| 2 mm | 1500 watts | 1350 watts | 500 | 30 | |

| 2.5 mm | 2000 watts | 1600 watts | 500 | 30 | |

| 3 mm | 2000 watts | 1850 watts | 500 | 30 | |

|

|||||

| Material | Peak laser power | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 1000 watts | 650 watts | 600 | 30 | |

| 1.5 mm | 1000 watts | 850 watts | 600 | 30 | |

| 2 mm | 1500 watts | 1100 watts | 500 | 30 | |

| 2.5 mm | 1500 watts | 1400 watts | 500 | 30 | |

| 3 mm | 2000 watts | 1750 watts | 500 | 30 | |

|

|||||

| Material | Peak laser power | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 500 watts | 300 watts | 500 | 20 | |

| 1.5 mm | 500 watts | 370 watts | 500 | 20 | |

| 2 mm | 500 watts | 480 watts | 600 | 20 | |

| 2.5 mm | 1000 watts | 600 watts | 600 | 20 | |

| 3 mm | 1000 watts | 760 watts | 700 | 20 | |

|

|||||

| Material | Peak laser power | Set the power | Speed (mm/sec) | Frequency (kHz) | |

| 1 mm | 500 watts | 320 watts | 600 | 20 | |

| 1.5 mm | 500 watts | 460 watts | 600 | 20 | |

| 2 mm | 1000 watts | 600 watts | 500 | 20 | |

| 2.5 mm | 1000 watts | 800 watts | 700 | 20 | |

| 3 mm | 1000 watts | 960 watts | 650 | 20 | |

Working in uncomfortable positions – gun weighing only 1 kg

Purchase procedure

-

Equipment selection

We assist you in making your choice of a machine matching your needs

-

Sending invoice

We agree on the complete set of the machine and sending the invoice with the final cost of the equipment.

-

Payment

In full if the machine is in stock. 50% in advance 50% at the delivery if the machine is not in stock.

-

We check the machine

The 3 step quality control: at the Wattsan factory, at our warehouse in the Netherlands, before the delivery.

-

Delivery or pick-up

Either a transport company or you pick up the machine from our warehouse.

-

Launching equipment

We are here to assist you whenever you need support.

Experiences from enthusiastic bloggers

Technical characteristics

Ask questions

-

The machines requires the minimum amount of consumables: nitrogen/argon and electricity, consumable electrodes are not required. Parts are welded without using a filler wire although it can be fed as an option.

-

The working surface does not need cleaning or polishing before and after welding. The surface cleanness is not so essential for laser welding as for MIG welding.

-

The laser welding machine suits for butt welds, fillet welds, T-welds, circumferential welds, ill-fitting items. The welding process results in a high-quality weld free from distortions and burn-through that does not require postweld treatment (due to a limited heat-affected zone).

-

The laser welding machine is able to weld: carbon steel, low-alloy steel, high-strength constructional alloys, stainless steels, aluminium, copper and brass alloys, titanium, plastics, dissimilar materials. Quick adjustment for a new material is available. Laser welding is easily integrated in a manufacturing process.

-

Laser welding is much more fire-safe as compared to traditional welding processes, no molten metal and hazardous sparks are ejected during welding. This makes labour conditions more comfortable.