We are surrounded by things made on a laser machine. You might even be unaware of this, but that decorative wall panel in your favourite bar, the engraved phone case, the cake topper on grannys birthday party, the nephew's educational puzzle toys, the bakerys sign on the corner outside your house all were made on a CNC laser machine.

But have you ever wondered how these machine tools work? Today, we are going to discuss where the laser emission comes from and how a laser machine moves so fast and precisely that it has already taken over the world.

In this article we will confine ourselves to carbon dioxide (CO2) lasers only and will not talk about ultraviolet and fiber optic laser machines as they belong to a different type of equipment.

What to produce on a CO2 laser machine?

CNC CO2 laser machines process organic materials. Such equipment performs two types of machining: cutting and engraving.

A laser machine cuts and engraves:

- wood, plywood, MDF, and other wood-based materials;

- polymers and plastics, such as PET, acrylic, polypropylene foam or foam;

- rubber,

- paronite,

- cardboard and paper

- fabric, fur, leather, and faux leather.

Engraves:

- stone,

- ceramics,

- glass and mirror.

If you combine these materials efficiently and have skills in industrial design or order product layouts from professional designers, you can produce amazing things that will make a hit in the market and bring profit to the machine owner.

Look for free stocks of layouts for laser cutting with prepared parameter settings in order to practice laser cutting.

These products are often in high demand in the restaurant business, advertising, interior and exterior design. The laser machine is used to produce childrens goods, toys, busyboards, labels, signs, directional signs, and fabric items, to engrave on leather items, to make customized jewelry-boxes, and much more.

Today the market for CNC laser cutting and engraving is growing steadily.

The range of possible products is only limited by imagination.

The machines range in size from large-format models with a working area of 2 by 3 metres to desktop CNC lasers with a working area of 50 by 30 cm. Thus, it is possible to start both large mass production and a small home-based business.

So, how does a laser machine work? Where does the laser emission come from?

How is laser created in a CO2 machine?

A laser beam is a narrowly focused monochromatic coherent stimulated emission initiated in an active carbon dioxide medium by an external energy factor.

Or simply put. A CO2 laser machine is equipped with a laser tube. It is a glass flask filled with a mixture of gases: carbon dioxide, nitrogen, and helium. The machine feeds electrical energy into the emitter, which is converted into the laser emission due to the gas mixture, mainly carbon. This is why such machine tools are called CO2 machines.

A laser machine converts electrical energy into laser emission thanks to a sealed glass flask with a carbon dioxide medium inside, called a laser tube or an emitter.

Unlike sunlight or lamplight, the laser does not scatter. This is because the photons that are emitted when a carbon molecule is excited have the same wavelength and travel parallel to each other.

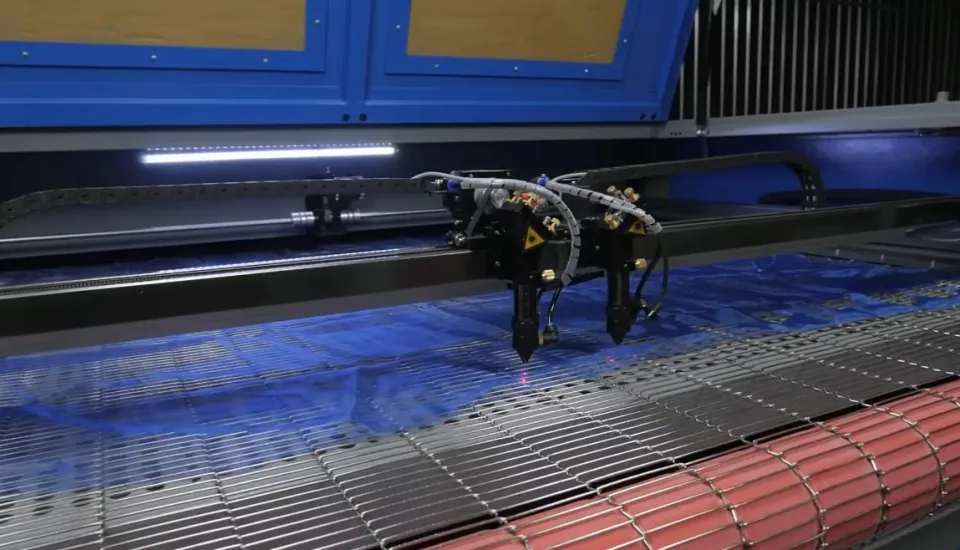

The laser beam exits the tube and is reflected by a system of moving mirrors that are installed on a machine. The first mirror is stationary and is mounted next to the emitter while the other two are mounted on moving parts of the machine so they can travel to any preset position.

But how does the machine know where to move?

How does the machine know where to move?

CNC stands for computer numerical control. It is a programming principle that lets moving parts of a machine to travel along the set path and initiate a laser beam with the required power at the required time.

The controller, a special board inside the machine, decides where to move and when to switch on the laser. There is a display with buttons for adjustment and control on the machines hull.

The working area of the machine is similar to a big chessboard with lots of squares coordinates. When you upload a layout in the machine and start operation, the controller begins playing chess with itself, determining from which square to which one to move and when to switch on the laser in order to perform the preset programme.

Modern RuiDa-type controllers are capable of performing both cutting and engraving in a single task. While M2-type controllers require a separate task for each operation type.

In order to start engines, the controller sends a signal through a driver, a device that tells engines in which axis, where, and how much to move the gantry or the working head of the machine.

If the machine moves the laser head slowly and sets a high power of emission during operation, we get such an intense impact on the material that the laser cuts through it.

Engraving, on the other hand, requires high travel speed and low power. The machine moves fast left and right, shifting step by step by 1 mm, as it were performing flooding by burning.

The laser head travels at the speed of up to 400 mm/s, and the controller manages to switch the laser on and off just in a fraction of a second in order to produce a high-quality image.

With the laser, highly detailed shapes and images are made due to a high resolution and a positioning accuracy of 0.01 mm.

Layouts are prepared in vector editing programmes, then exported to RD Works, and there converted to a machine-readable code. In RD Works, the cutting and engraving parameters and other settings are set, and the machine does the rest.

The advantages of laser processing

Laser cutting and engraving is popular and in high demand due to a number of advantages:

- Processing speed. Engraving is performed at a speed of up to 400 mm/s, and cutting at a speed of 1-150 mm/s depending on the material and its thickness.

- A list of materials: wood, plywood, MDF, chipboard, acrylic, PET, foam, and other plastics and polymers, rubber, paronite, stone and ceramic, mirror and glass, cardboard, paper, different types of fabric, fur, and leather.

- No additional peripheric tools and consumables, but for a laser emitter. If used properly, a laser tube will last up to 3 years depending on power and manufacturer.

- High quality of a final product. Laser cutting produces a perfectly even and smooth edge, and when engraving, you can adjust the parameters to achieve the desired image contrast.

- The small diameter of a laser beam allows you to arrange items back to back on a sheet of material saving material.

- The production is characterized by low noise and dust levels.

What machine tool to buy?

Laser machines are conventionally divided into two types: engravers and cutting machines.

Any laser machine can both cut and engrave, but laser engravers differ in the following parameters:

- working area size from 200*300 mm to 600*400 mm;

- most often, these are tabletop models;

- laser tube power from 20 W to 60 W.

Features of the laser cutter:

- working area size from 900*600 mm to 2000*3000 mm;

- stand type model, which takes up more space in a working shop;

- laser tube power from 90 W to 180 W.

Therefore, before buying a machine, it is better to determine the tasks you plan to perform and the products you want to produce on the purchased machine.

If you want to cover the widest range of tasks, choose a medium format machine with a working area of 900*600 mm or 1200*900 mm, for example the Wattsan 6090 or the Wattsan 1290, respectively.

16 features of a good CNC laser machine:

Bed

When operating, especially during engraving, the machine sustains heavy inertial loads from the moving of a laser head. This creates vibrations that negatively affect the quality of machining. A solid durable frame eliminates vibrations. Ideally, there should be a reinforced frame inside the housing, as on Wattsan machines.

Body thickness

The body thickness should be at least 2 mm as this also affects the rigidity of the machine structure, especially for large format models with a big working area size. The Wattsan laser machine body is 2.9 mm.

Gantry

The thickness and reliability of the portal affects the preservation of accuracy characteristics during long-term operation of the machine at high speeds. Wattsan machines are equipped with a reinforced aluminium gantry up to 9 mm thick at the corners.

Engines location

If the Y-axis engine is situated in the right or left corner of the body, this causes distortion of the geometry during operation. The only correct location of the engine is in the middle of the Y-axis shaft.

Gearboxes

Gearboxes split the engine pitch, i.e. increase the resolution and also take the load off the motors. The gearboxes ratio on Wattsan machines is ⅙.

Belts

Belts are a machines weak point; if they are not reinforced, they tear quite often. Wattsan machines come with reinforced belts with 3M tooth pitch.

End sensors

Inductive end sensors are more reliable than mechanical ones because they are not prone to mechanical exposure and therefore serve longer. Moreover, inductive sensors are not affected by dirt, soap, and resins, unlike the mechanical ones.

Blowing hoses

This is another weakness of low-quality machines. If you apply more than one atm, the blowing hose will tear away where it is attached to the laser head. In order to get a clean cut, you need 2 atm. The polyurethane blowing hoses on Wattsan machines can withstand up to 8 atm.

Optics and mirror system

Pay attention to the working head, especially to the lens mount and the mounting of the head to the gantry. Easy access for lens cleaning helps during maintenance. The mirror screws for alignment of the optical path should be convenient. Mirror mounts must move in all axes for adjustment.

Nozzle diameter

This parameter affects the quality of blowing and therefore the quality of processing. Laser engravers, such as the Wattsan 0503, are equipped with an expanding nozzle for less intense blowing during engraving in order to prevent the combustion products from being pinned to the material surface by the air flow. While on laser cutters, such as the Wattsan 6090, a reduced nozzle is installed that concentrates the air flow, which improves the quality of cutting.

Tray for garbage collection

A good machine is equipped with a tray for garbage collection inside the housing. This affects the ease of operation and also reinforces the bodys structure, protects the table lifting mechanism, and improves smoke extraction.

Table lifting mechanism

A chain lifting mechanism is better than the belt one because it will not break during operation.

Safety

Machine electronics located near the machine's water supply systems are a hazard. It is safer to locate these elements on opposite sides of the machines body.

Laser tube mounting

The laser tube mounting with adjustment screws allows you to set up its position without removing the emitter.

Blades and honeycomb table

Anodized blades prevent the laser beam from firing back at the back side of the material. While an iron honeycomb table uses neodymium magnets to hold thin materials such as fabric and fur.

Potentiometer

The potentiometer (amperemeter) on the machines body allows you to manually select the emission power using a regulator. This allows for finer manual adjustment, gives more engraving possibilities, and lets you set lower than those that can be set programmatically values.

For more information about this topic, please write your questions in the comments or contact your Virmer manager.