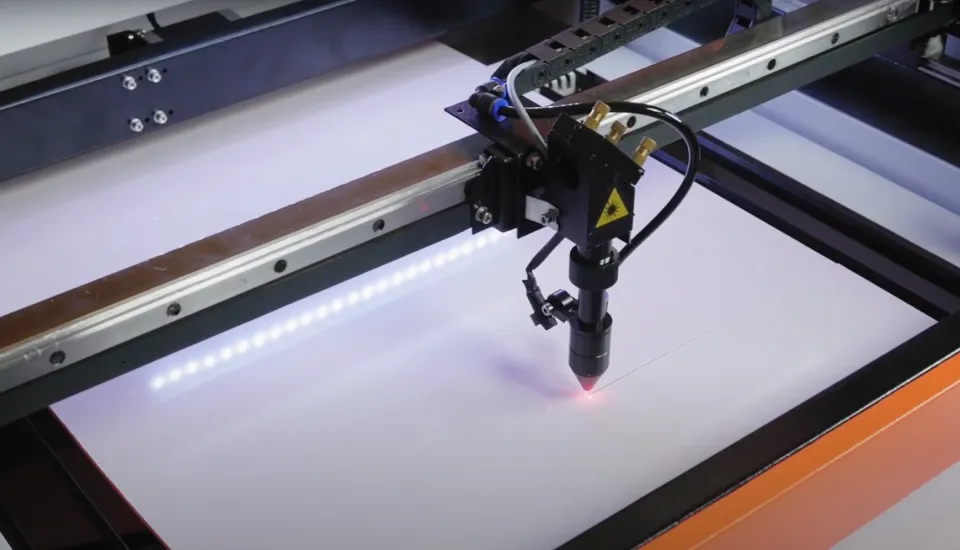

The laser machine for fabric can cut out and engrave various types of textiles — both natural and synthetic. Machines with a CO2 emitter are used for laser cutting of fabrics.

In this article we will tell you what are the advantages of laser cutting of fabric and its engraving, what types of textiles are suitable for this, what can be done with this type of processing, what are the features when choosing a laser machine for fabric, and also give some tips on laser cutting of fabric and its engraving.

Advantages of laser cutting of fabric on a CO2 machine

Laser cutting of fabric, as well as laser engraving, is actively capturing the textile production market, as it has a number of advantages:

- Working speed. The speed of laser cutting of fabrics reaches 400 mm/s, and the speed of engraving is 600 mm/s;

- Controlled partial melting. During laser cutting of fabric, the laser beam melts the edge of synthetic materials, which prevents fraying. This is especially true for loose fabrics.

- Cutting fur without damaging the pile. With the help of a laser machine for fabrics, with the correct setting of parameters, it is possible to cut out fur without damaging the pile;

- CNC. Computer numerical control of the laser machine for fabric minimizes the probability of reject, since it eliminates the human factor during laser cutting of fabrics, while guaranteeing absolute repeatability of products and accurate cutting along complex trajectories;

- Fineness of the laser beam. The diameter of the laser beam is 0.012 mm, which allows precise laser cutting of fabrics along thin contours;

- Positioning accuracy. The precision of laser cutting of fabrics is 0.03 mm, which allows you to cut high-precision figures, patterns and lace with a high degree of detail;

- Service life of the cutting tool. Since the cutting tool is a laser beam, it does not blunt, unlike traditional methods of cutting fabrics. Laser CO2 tubes are designed to work up to 10,000 hours without replacement. At the same time, laser cutting of fabrics takes place at a minimum power, which can significantly extend the claimed service life;

- Easy to learn. To master the basics of working on a laser machine for fabric, one day of training is enough;

- Low noise level. The process of laser cutting of fabrics and the movement of the laser machine units do not create a high level of noise. The loudest when laser cutting fabric are the exhaust hood and compressor ;

- Multipurposeness. The laser machine for fabric can cut and engrave not only textiles, leather and fur, but also plywood, veneer, MDF and other wood materials and almost all types of plastics. You can also engrave glass, stone and ceramics.

What types of textiles are suitable for laser processing?

Almost all types of textiles can be cut on a laser machine for fabric. It is also possible to cut materials that are used as a lining. Some fabrics can not only be cut, but also engraved on a laser machine on the fabric.

List of textile materials for laser cutting:

- cotton and linen,

- silk,

- knitted,

- artificial and synthetic,

- fleece,

- kevlar,

- polyester,

- polyurethane,

- polypropylene,

- polyamide,

- nylon, including armored tarpaulin,

- blended fabrics,

- woven and plush fabrics,

- technical and heat-resistant textiles,

- furniture fabrics and foam rubber,

- cushioning and lining fabrics,

- velcro,

- natural and artificial leather,

- natural and artificial fur.

What can be done on a laser machine for fabric?

As you have already understood, when using laser machines for fabric in industry, two main types of processing are possible — cutting and engraving.

Laser cutting of fabric

The radiation of the laser machine for fabric has a small, but very concentrated zone of thermal impact. Due to this, textile materials are carefully and without ignition of adjacent areas are burned or melted at the focus point of the laser beam.

Laser cutting of fabric is usually used for several purposes:

- Setting up technology, creating patterns. Laser machines for fabric are convenient because you can easily and quickly correct the dimensions or lines of the layout directly in the program to achieve the desired result;

- Final or intermediate laser cutting of fabric. A laser machine for fabric can create both a final product, for example, polyester filters that can be sold immediately, and an intermediate product — cut fabrics intended for further stitching (clothing, toys, furniture);

- Decoration. With the help of laser cutting of fabrics, you can make chevrons and stripes, cut fabrics along a complex contour, create lace.

Laser engraving of fabric

Engraving with a laser machine for fabric is obtained by reducing the emission power to such values that the laser beam does not burn through the material, but only removes it to a predetermined depth. In this way, you can create patterns, images and inscriptions on the surface of the material without violating its integrity.

The best fabrics for laser engraving are non-woven materials such as felt or pile fabrics, such as fleece. When engraving on fleece, a pleasant tactile effect is obtained.

Among the woven materials, dense denim may be suitable. It is important to adjust the engraving parameters so that the laser beam vaporizes the paint without destroying the fabric. Laser engraving of other woven materials is likely to damage the fibers.

How to choose a laser machine for fabric

There are special laser machines for fabric, which are somewhat different from the usual models of CO2 laser machines. The basic principle of operation remains the same, but there are important differences that make working with fabric more convenient and productive.

If you are faced with the topic of choosing a laser machine for the first time, we recommend reading our article: "How to choose a CO2 laser machine". In this article you will find all the main parameters that affect the choice. Now we will focus on the features of models designed for laser cutting of fabrics.

The size of the working field of the laser machine for fabric

The most important thing is that the size of the working field should be wider than the rolls of fabric. The most common width of the material is from 1.1 to 1.5 m. In addition, it is desirable to take into account an additional allowance of at least 5 cm on both sides of the material. Thus, the width of the working field for laser cutting should be at least 1.6 m.

Broaching table of a laser machine for fabric

In most cases, the length of the fabric roll is from 36.5 to 91.5 m. In order to be able to carry out laser cutting of fabric in rolls without preliminary cutting, laser machines for fabric are equipped with a special technical hole in the housing at the level of the working field.

As a rule, a roll of fabric is fixed on a roll-unwinder at the back of the machine, then the fabric is stretched onto the working field, secured with pressure shafts and stretched as it is cut into the working area.

Conveyor table of laser machine for fabric

The conveyor table is a mechanism that helps to pull a roll of material into the working area for laser cutting of fabric. The main advantage of such a design is that it performs automatic material transfer and makes the work almost continuous.

In standard machines that are not designed for laser cutting of fabrics, in the usual configuration, the working field of the machine is equipped with lamellae — it is on them that the material for cutting and engraving is usually laid. In the case of fabric, this is not very convenient, since it can sag between the lamellae, which leads to defocusing of the laser beam and under-cuts during laser cutting of fabrics.

Power of the laser tube of the laser machine for fabric

Laser cutting of fabrics does not require a high-power laser tube. Laser tubes with a power of 100-120 watts can be considered the highest of the appropriate values. Excessively high power will be an overspend, besides, it will not allow engraving fabrics, since the laser will burn through the material.

Potentiometer of the laser machine for fabric

All laser tubes have a minimum ignition threshold, which is equal to 10% of the maximum power. This means that a laser tube with a power of 100 watts simply will not be able to turn on at a power of less than 10 watts. This circumstance can be especially important when engraving fabrics.

The potentiometer allows you to manually adjust the laser radiation power indicator and achieve lower values right during laser cutting of fabrics.

Top machines for laser cutting of fabrics

We have selected the best laser machines for fabric for you. The bed of the Wattsan machines is equipped with a reinforcement frame, and the thickness of the body is 2.9 mm, which makes the machine as stable as possible and eliminates vibrations.

Laser machines for Wattsan fabric are equipped with three-phase motors with gearboxes, reinforced belts with a tooth pitch of 3M, reinforced aluminum portal, reliable guides and inductive end sensors.

In the assortment of Wattsan laser machines there are specialized models designed for laser cutting of fabrics, and they will be discussed now.

Laser machine for fabric Wattsan 1610 Duos Conveyor

This model is suitable for continuous laser cutting of fabric, leather, leatherette and any other rolled materials. Wattsan 1610 Duos Conveyor is equipped with two working heads at once, which allows you to speed up production twice.

Power: 100-120 W;

Conveyor table

Working field size: 1600x1000mm;

Engraving speed: 0-600 mm/s

Cutting speed: 0-400 mm/s

Price: from 11,375 €

The current price and detailed characteristics of this laser cutting machine for fabrics can be found on the website or check with Virmer managers: +31208082045 or е-mail: info@virmer.com.

Laser machine for fabric Wattsan 1610 Cam Conveyor

The Wattsan 1610 Cam Conveyor laser cutting machine for fabric is equipped with a Canon camera mounted above the working field. The camera recognizes and scans contours, which makes it possible to laser cut fabrics or printed sheets, cut chevrons and perform other tasks where contour recognition and work on them are necessary.

Power: 100-120 W;

Conveyor table

Working field size: 1600x1000mm;

Engraving speed: 0-600 mm/s

Cutting speed: 0-400 mm/s

Price: from 15799 €

The current price and detailed characteristics of this laser cutting machine for fabrics can be found on the website or check with Virmer managers: +31208082045 or е-mail: info@virmer.com.

Conventional laser machines are also suitable for laser cutting of fabric. For example, Wattsan 2030 FlatBed is suitable both for working with various non-metallic materials: plywood, veneer, acrylic and plastics, and for laser cutting of fabrics of large and non-standard sizes.

Power: 100-120 W;

Engraving speed: 0-500 mm/s

Cutting speed: 0-350 mm/s

Price: from 16747 €

The current price and detailed specifications of this laser cutting machine for fabrics can be found on the website or check with Virmer managers: +31208082045 or е-mail: info@virmer.com.

Tips for laser cutting fabric

Laser cutting of fabric has its own nuances, so we have prepared for you some tips from VIrmer engineers.

Laser cutting power of fabric

Laser cutting of fabrics most often does not require much power. As a rule, 10% to 30% of the power is sufficient. The small power of operation also prolongs the service life of the laser tube.

Laser cutting speed of fabric

Speed and power are interdependent — the higher the speed, the more power is required. It is also worth considering that for cutting layouts with a lot of details, for example, lace patterns, the maximum speed will be limited to 150 mm /s. Otherwise, it is difficult to achieve high-quality cutting due to the inertial effects obtained due to the rapid acceleration and deceleration of the laser head.

Laser engraving of fabric

For laser engraving of fabrics, the main thing is to choose the right parameters so as not to burn through the material.

If the fabric is burned or torn when checking for rupture, you need to increase the speed or reduce the power, including using a potentiometer. If adjusting the speed and power indicators does not achieve the desired result, you can slightly defocus the laser beam.

Blowing force during laser cutting of fabric

We recommend setting the airflow to a minimum so that the air flow does not lift the material during the laser cutting of the fabric. To do this, you will need a compressor with the ability to adjust the blowing force.

Laser cutting of fur

In order to cut fur properly, it is necessary to turn it pile down and adjust the cutting parameters so as to carefully cut through the leather without damaging the pile.

Conclusions

Laser machines for fabric have found wide application in the textile industry — starting from the serial cutting of textiles and the preparation of patterns and ending with the lace cutting of patterns with complex trajectories.

You can come to our showroom in the Netherlands or get an online demonstration with a consultation.

For detailed advice on laser machines for fabric, please contact Virmer managers: +31208082045 or е-mail: info@virmer.com.