With the help of laser engraving, contrasting and durable images and inscriptions can be applied to the leather. Laser machines for engraving leather are used for decorating leather products, applying logos and distinctive signs. Moreover, on some laser machines it is possible not only to engrave, but also to cut leather and other materials.

In this article we will tell you:

- How Leather Laser Engraving works

- What are the advantages of laser engraving of leather;

- What leather type can be engraved with a laser?

- What can be done with the leather using a laser machine;

- What kind of laser machine is needed for engraving leather and cutting it;

- Which models of laser machines are suitable for engraving leather;

- Tips for laser engraving of leather.

How Leather Laser Engraving works

The laser beam originates in the source of the laser machine and enters the leather surface via the optical system through the focusing lens.

There are two similar types of exposure that inexperienced users often confuse: engraving and marking. They differ in that when engraving, the laser beam burns out a thin surface layer of the leather, and the marking simply changes its color.

At the same time, both engraving and marking are resistant to abrasion. Technically, both engraving and marking are obtained by almost the same way, only the working settings differ: speed, power and, in some cases, frequency.

Later in this article, for convenience, we will use the word "engraving", meaning both of these processes, if there is no need to indicate fundamental differences.

To create a laser engraving on the leather, you need to prepare a layout in vector or raster format, load it into the machine, set the settings and start the machine. Learning the basics of working on a laser machine on the leather takes only a few hours.

Advantages of leather laser engraving:

Manufacturers of clothing, accessories and other leather products appreciate the following advantages in laser machines for leather:

- Accuracy and repeatability. The diameter of the laser beam is 0.012-0.0012 mm, and the positioning accuracy of laser machines reaches 0.003 mm. Laser machines engrave images on leather with one hundred percent repeatability and so many details that cannot be obtained by embossing;

- Speed The speed of laser engravers on the leather reaches 700 mm/s, and the speed of laser markers can reach 20,000 mm/s;

- Flexibility and cost-effectiveness. To create a laser engraving on the leather, no additional tools or creating a cliche are required. It is enough to prepare a vector or raster layout, select the settings and start the machine in operation. From the above it follows that there is an economic benefit when working even with small print runs;

- High-quality image and stable result. Laser engraving of leather produces a high-contrast image with a detail of 2500 DPI. The applied images are resistant to abrasion and mechanical influences. The service life of a properly applied laser engraving on high-quality leather is equal to the service life of the material itself.

What leather type can be engraved with a laser?

The laser machine for engraving leather is capable of applying images and inscriptions to almost any type of this material. But there are nuances.

Laser engraving of natural leather

The laser is able to engrave any natural leather: smooth, aniline, lacquer leather, nubuck, velour, suede, plonge lambskin, chevrette, polished and pressed leather from almost any source material: hides of cattle, horses, sheep, goats, camels, pigs and deer.

Please note that even with the same supplier, the quality of the leather may differ from one delivery batch to another. Therefore, we recommend that you always carry out a test laser engraving of leather when receiving a new batch in order to select the optimal parameters.

Laser engraving of leatherette

In addition to natural leather, the laser machine also engraves its numerous artificial substitutes, including some of those that are not suitable for manual processing.

Suitable for laser engraving: smooth leather, embossed, lacquered, matte, eco-leather and artificial suede.

Materials containing PVC cannot be processed on a co2 laser machine, since when burning, this material releases hydrogen chloride and cumulative poisons, such as dioxins, which irritate the mucous membranes of the eyes and respiratory tract and can lead to death with a large dosage or prolonged exposure.

Despite the fact that most types of artificial leather are well engraved with a laser, we do not recommend doing intensive engraving of this material, since with deep exposure, the engraving will be short-lived. It is better to do shallow engraving or marking.

What can be done with laser engraving of leather

Laser engraving of leather is used in the manufacture and decoration of clothing items, accessories and other leather products. Thanks to CO2 laser engravers, it is possible not only to engrave, but also to cut the leather. This functionality does not apply to laser markers. Laser cutting of leather is used both for cutting material for specific products and for decorating it — for example, cutting openwork patterns.

With the help of laser machines, original drawings, emblems and logos, greeting and personalized texts and images are applied to the leather. Laser is often used to engrave leather covers of notebooks, sketchbooks and day planners, identity cards and passports, phone cases and glasses, business card holders, wallets and key holders, shoes and clothing items.

The scope of application is limited only by your imagination, the main thing is to choose a high-quality machine.

What kind of laser machine is needed for engraving leather and cutting it

Laser machines for leather may differ in the type of emitting source and in the design and method of engraving. First you need to determine exactly these characteristics, and only then look at the power and other parameters.

Emitter type of laser machine for leather

Laser machines for engraving leather are divided into three main types: gas-discharge, fiber-optic and ultraviolet. They differ in the wavelength of radiation, the wavelength affects which materials other than leather will be engraved.

Gas-discharge CO2 emitters

Suitable for organic materials:

- plywood, veneer, MDF, various types of wood,

- plastics (except PVC),

- stone and ceramics,

- glass and mirror,

- textile

Fiber-optic emitters

They interact better with inorganic materials, especially metals. With laser engraving of leather, the interaction occurs not with the material itself, but with tannins and dyes, so not all leather types will be treated equally well, it is necessary to test. Fiber-optic emitters can also engrave plastics.

UV emitters

They have the widest range of processed materials — in fact, they can process almost any material. They are used in microtechnics and jewelry industry for engraving precious stones. High-quality UV laser emitters are quite expensive, it is impractical to buy them for engraving leather, so in this article we will not focus on them.

Design of a laser machine for engraving leather

There are two types of laser engraving machine designs for leather:

- engravers with flying optics system,

- galvanometric markers.

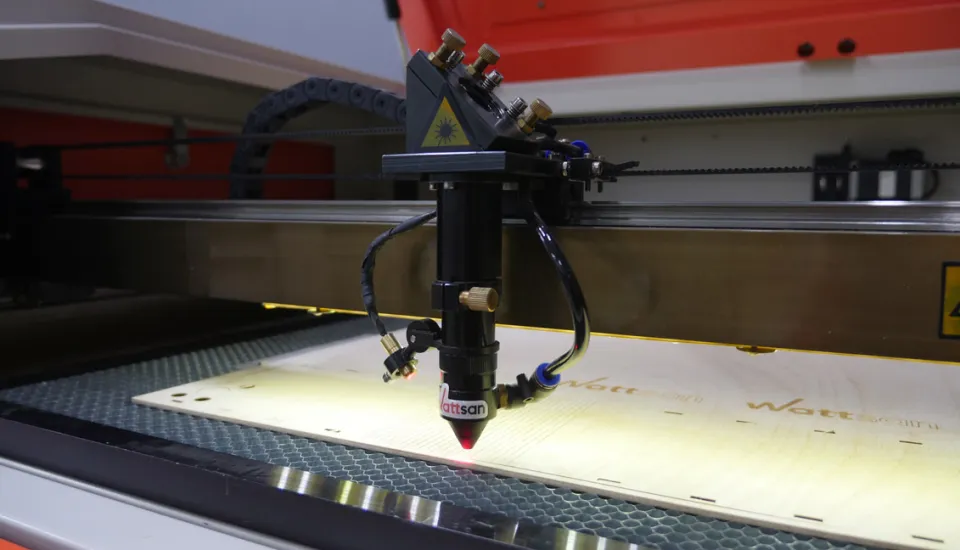

Laser engravers and leather cutters with flying optics system

They can only be equipped with a CO2 emitter. This type of design allows not only to engrave, but also to cut leather and other materials available for operation by carbon dioxide emitters.

CO2 laser engravers and cutters have a wide range of working field sizes:

- 200x300 mm,

- 500x300 mm,

- 600x400 mm,

- 600x900 mm,

- 1200x900 mm,

- 1600x1000 mm,

- 2000x3000 mm.

The speed of operation depends on the model, for Wattsan laser machines it is usually 500 mm/s for cutting and 700 mm/s for engraving.

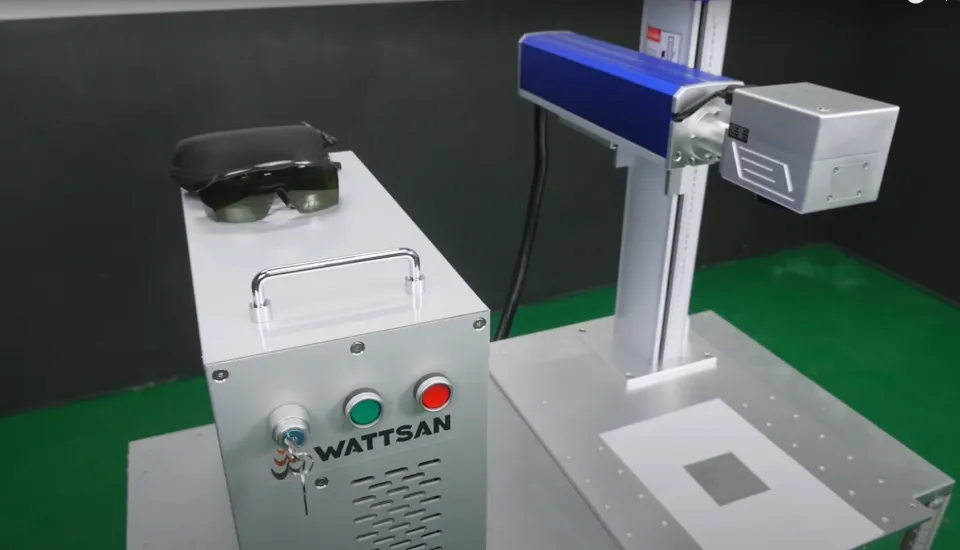

Galvanometric laser markers on leather

They can be equipped with both CO2 and fiber-optic or ultraviolet emitter.

The markers direct the laser beam through a galvanometric scanner with high-speed movable mirrors through a focusing lens to the surface of the material.

The working field size of laser markers depends on the lens, the main dimensions:

- 110x110,

- 200x200,

- 300x300.

The speed of operation depends on the model, the most common speed is 5000-7000 mm/s, which is 10 times faster than the speed of laser engravers with flying optics. Some laser markers operate at speeds up to 20,000 mm/s.

Which is better — a laser engraver or a laser marker on the leather?

Laser CO2 engravers for leather make sense to choose in two cases:

- You need to engrave products or sheets of leather with a size of more than 300x300 mm;

- You need not only laser engraving, but also laser cutting of leather.

If you need to process artificial leather in rolls, pay attention to the Wattsan 1610 Duos Conveyor laser machine. It allows you to work almost continuously due to the fact that the conveyor table can stretch the material by unwinding it from the roll. In addition, this model is equipped with two working heads that work simultaneously.

In other cases, the size of the working table and the model of the laser machine for engraving leather will depend on what exactly you plan to do.

The universal solution will be the Wattsan 6090 ST laser machine or a model with a large working field size - Wattsan 1610 ST.

If you have to work with small leather products and increased productivity is important for you, it is better to choose a laser marker. If you plan to combine leather processing with metals, then you need Wattsan FL LT or Watssan FL TT. If metal processing is not needed, it is better to choose the Wattsan CO2 LT gas discharge marker, since CO2 emitters work better with the leather regardless of how it was treated.

Power of the laser machine for engraving leather

Laser engravers and cutters for leather are mainly equipped with emitters from 40 to 120 watts. Emitters with a power of more than 60 watts may be needed if you need laser cutting or fast deep engraving. In other cases, a laser tube with a power of up to 60 watts is sufficient. An example of an excellent desktop laser engraver is Wattsan 0503.

Laser markers are equipped with emitters of various capacities depending on their type:

CO2 markers — 50 to 80 W;

Fiber-optic markers - 20 to 50 watts, in rare cases — up to 100 watts;

UV markers — 3 or 5 watts.

The higher the power, the faster the laser engraving of leather can be done. And the lower the power, the easier it is to adjust the degree of exposure and to mark. For marking, it is preferable to choose emitters with a power of up to 30 watts. If you need a deep contrast engraving, it is better to choose more powerful emitters.

Tips and features when engraving leather

With laser engraving of leather, a strong smell cannot be avoided, so the machine must be equipped with a powerful extractor hood.

The finished product with laser engraving can also have an unpleasant smell, to get rid of it, try to rinse it and leave it in a ventilated room for up to 3 days. To achieve the best effect, place ground coffee next to it.

If carbon deposits appear on the leather from laser engraving, it can be removed with an eraser or a soft brush. Also, before engraving, you can seal the processing area with masking tape.

The color of the resulting engraving depends not only on the settings, but also on the type of leather, its quality, dyes and tannins.

Before laser engraving, be sure to do a test work on a test sample or a piece of leather.

To fix the leather on the working field of a laser engraver or cutter, use a honeycomb table and neodymium magnets.

Conclusions

Choosing a laser machine for engraving leather is not so difficult if you know what tasks it is needed for. Nevertheless, there are universal solutions that are suitable for a wide range of purposes.

Our task is not only to sell you a machine, but also to help you make money on it, so we share all the knowledge and experience that we have. If you need advice on choosing a laser machine for engraving leather, please contact Virmer managers: info@virmer.com ; WhatsApp +31852731786.

Choosing Virmer, you get a guarantee, fast delivery, assistance in commissioning and training from our engineers.