Operating principle of the laser marking machine

The laser beam is formed in the emitter and then directed to the galvanometer scanner equipped with two motors with inductive rotor position sensors. The motors are equipped with mirrors that reflect the laser beam to the desired point on the plane.

Before reaching the material, the laser beam passes through an F-Theta lens, which focuses it to a point up to 0.01 mm in diameter.

When the laser reaches the material, it can burn through its top layer to obtain laser engraving; or it can change the properties of the material by thermal impact, e.g., to change the material color and create so-called temper colors or apply laser marking.

In some cases, the laser can vaporize the top layer of material, e.g., ablate the top layers of wood or remove the anodic coating from aluminum without damaging the base material.

Advantages of a laser marking machine:

- The speed of laser engraving is up to 20,000 mm/s, which is at least 28 times faster than laser engraving speed of CO2 laser engravers;

- Detailing 2500 DPI, laser engraving accuracy 0.01 mm;

- The engraved data is durable, indelible, and resistant to erasure;

- The laser marker applies the information in a non-contact manner;

- Power consumption is approximately 600 W/hr;

- The laser marking machine is capable of operating 24 hours a day without interruption;

- Compact housing; the laser marking machine fits easily on the table;

- Does not require maintenance by qualified personnel; machine maintenance can be performed by the operator;

- No consumables required;

- Easy to master;

- CNC (computer numerical control) minimizes rejects and ensures the complete identity of products.

What products can be made with a laser marking machine

A laser marker can be used to apply laser engraving and laser marking to almost any material and surface.

Laser marking is used to apply data in the form of images and inscriptions on the packaging and the goods directly. The laser is used to print technical product information, bar codes, QR codes, logos, and serial numbers. Laser engraving is also used for branding products and making souvenirs, including personalized gifts.

In addition, laser markers are used in jewelry, mechanical engineering, as well as for laser marking of medical and any other tools, cables and pipes, spare parts, and other products.

Selection criteria for a laser marking machine

The criteria for choosing a laser marker depend on what materials you will be working with and what type of main activities will be performed. The main criteria are the type and power of the laser emitter, the lens of the laser marking machine, and the design of the machine itself.

Type of laser marker emitter

Carbon dioxide (CO2) laser marking machines are designed for laser marking and laser engraving of non-metallic materials such as plywood and any wood materials, fabrics, leather and faux leather, mirror and glass, rubber and plastics, stone and ceramics.

There are two types of CO2 laser emitters:

- Standard laser tube. The best choice would be Tongli laser tubes: power 50-80 W, service life of 6,000-10,000 hours, small beam divergence, and small diameter of the laser beam. A chiller is additionally required to cool any CO2 laser tube.

- High-frequency radiofrequency pumping (RF) emitter. Service life 10 years, refillable. Accuracy: 0.0012 mm, which is 10 times higher than conventional CO2 laser markers. Due to the possibility of adjusting the emission frequency and the features of the emitter design, it ensures more stable emission, a more regular mode, and most importantly, a smaller beam size, due to which the power density and efficiency are increased. No chiller required due to air cooling.

Fiber optic ytterbium emitters are suitable for laser engraving and laser marking of all metals, including ferrous metals, stainless steel, aluminum, titanium, brass, precious metals such as gold and silver, as well as various plastics, rubber, leather and faux leather, fabrics.

The market offers numerous laser emitter manufacturers, the main ones being MaxPhotonics, Raycus, JPT, and IPG. IPG emitters are the market leader; they have higher quality specifications and a wider frequency range, so they produce more shades on metals. These emitters are more stable and have protection against dangerous reflections.

The JPT transmitter with the MOPA design is particularly noteworthy. Its advantages:

- maintains high peak power at different repetition rates, different pulse durations, and high pulse repetition rates;

- the pulse front rises and falls quickly when switching on and off;

- zero delay of the first pulse;

- regular pulse matrix;

- no energy leakage.

These features provide a wider range of possibilities with high result stability.

Power of laser marker emitter

Power over 50 W is best suitable if you need high-speed laser engraving, deep engraving, or when you work with highly reflective metals such as silver to overcome the reflection threshold to interact with the metal.

If you need laser marking, especially color laser marking on metals, the best suitable power range is 20-30 W. Otherwise, a high-power laser will burn the material because the pulse energy is too high, and it will be difficult to select the settings to obtain a quality result.

Laser marker lens

The lens affects the size of the working field of laser marking and engraving, as well as the efficiency of the laser, while all other characteristics being equal. The smaller the size of the working field, the smaller the diameter of the focused laser beam, and therefore the higher the power density, i.e., the more impact on the material is more intense.

110x110 lens is more suitable for laser engraving. 200x200 and 300x300 lenses are best used for laser marking. Ideally, it is better to have several lenses at once for various tasks.

For an online demonstration of the differences, please contact Virmer managers by phone: +31208082045 or е-mail: info@virmer.com.

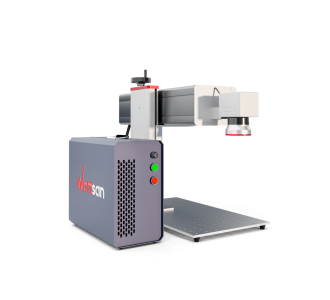

Design of the laser marking machine

Laser marking machines are supplied with different types of housing, as well as with different focusing options.

In terms of the type of housing, the machines can be distinguished as follows:

- Standard desktop laser marker;

- Marking station: a finished workstation with a compartment to house the machine itself and the work PC;

- Laser marker with a protective booth: indispensable in conditions of increased safety requirements;

- Portable laser marker: equipped with a detachable scanner for laser marking and engraving in hard-to-reach places and on oversized products.

Focusing options:

- Movable table: with a stationary scanner, an attachable table with adjustable height is used;

- Movable scanner: mounted on a vertical axis along which it moves; focuses when the points of the two laser pointers on the scanner are aligned;

- Autofocus: designed like a movable scanner, but focuses automatically at the press of a button;

- Dynamic autofocus: changes focus during operation according to the task; suitable for 3D engraving and engraving on curved surfaces.

By choosing Virmer, you get:

- Professional advice and answers to your questions,

- Warranty for laser marking machines,

- Reliable delivery,

- Assistance in starting-up and adjustment work,

- EZ CAD software for working with a laser marker,

- Basic training on how to work on the machine.

Feel free to contact the Virmer managers for detailed advice: +31208082045 or е-mail: info@virmer.com.