Laser engraving of glass is a technology for processing glass and finished glass products, with the help of which patterns and inscriptions of any complexity and detail are applied to the surface of the material. Glass laser engraving gives the products a unique look, improves their aesthetic properties, and also increases the final cost.

In this article we will tell you what you can do with glass laser engraving, what are the advantages of this method, how glass laser engraving works, which glass is suitable for this and how to choose a laser engraving machine.

What can be done with glass laser engraving

With the help of a glass laser machine, both flat and cylindrical surfaces can be engraved.

Laser engraving of sheet-type glass is used to create:

- Glass signs, plates and pointers;

- Branding of glass entrance doors and windows of boutiques and shops;

- Decoration of mirrors and interior doors;

- Creation of souvenirs, key chains, prize and award products;

- Personalized engraving on glass gifts: perfume bottles, figurines, paintings

Laser engraving of cylindrical glass blanks and products involves engraving glasses, mugs, bottles, as well as cylindrical souvenirs and award glass products.

Advantages of glass laser engraving:

Laser engraving of glass in comparison with other methods has a huge number of advantages:

- The accuracy of glass laser engraving is 0.03 mm. With the help of a laser machine, any photographically accurate images and inscriptions with a resolution of more than 2500 DPI can be applied on glass;

- The speed of laser engraving of glass is up to 700 mm/s. Time savings of up to 80% compared to other methods;

- Durability. The service life of glass laser engraving is equal to the service life of the material on which it is applied.;

- Contactless method. The laser machine on the glass does not come into contact with the surface of the material, this reduces the likelihood of reject, the appearance of internal defects and the danger of breaking the glass;

- Cleanliness of production. Laser engraving of glass does not require additional respiratory and visual protection from glass chips and dust;

- Economy. Compared to some other processing methods, for example, sandblasting, laser engraving of glass is less expensive, since only electricity is needed;

- Low probability of reject. Numerical Control (CNC) reduces to zero the probability of reject, gives the absolute identity of the applied images, eliminates the human factor from the process of applying laser engraving on glass;

- Does not require pre- or post-processing. Laser engraving of glass does not require the preliminary creation of stencils, and after work, engraving is already the final product;

- Low noise level. Glass laser machines can be used even at home, as they work very quietly;

- Easy learning. To master the basics of working on a glass laser machine, it is enough to spend two to three hours;

- Multipurposeness. The glass laser machine can not only engrave glass, but also cut and engrave other materials: plywood and any other wood materials, various plastics, leather and textiles, ceramics and stone and other materials.

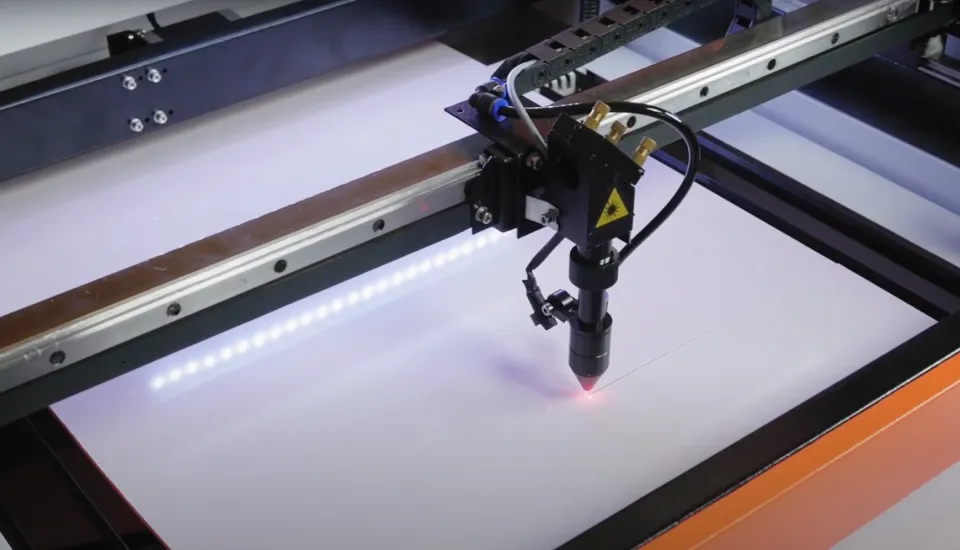

How Glass Laser Engraving works

For laser engraving of glass, laser machines with CO2, that is, carbon dioxide emitters, are used. This type of emitters has a wavelength of 10.6 microns, which is ideal for glass laser engraving.

Laser machines on glass with CO2 emitters are a little more complicated than an office printer. All you need for laser engraving of glass is to send the prepared file for engraving to the control program of the laser machine, set the focal length, speed and power parameters and press the “start” button.

The laser engraving of glass itself occurs due to thermal effects, as a result of which micro-explosions are formed on the surface of the material.

Thus, glass laser engraving occurs only at the point where the laser hits, and the glass around is not exposed to any effect.

Types of glass laser engraving:

Laser engraving of glass can be done by filling or by contour. According to the method of laser beam exposure to the material, both of these methods are identical, only the method of program exposure and the speed of task execution differ.

Laser engraving of glass by filling method

It is a classic method of glass laser engraving, when the laser head moves along the portal along the X axis, sequentially shifting by a given step along the Y axis. Thus, the laser gradually fills the image from top to bottom or from bottom to top and a ready-made laser engraving of glass is obtained.

Contour laser engraving of glass

This method significantly speeds up the process of glass laser engraving, but is only suitable for engraving fine lines. That is, it is impossible to fill with this method and get a solid image.

Contour laser engraving of glass is essentially a laser cutting, but at low power. The laser beam acts minimally on the surface of the material and results in engraving instead of cutting.

Which glass is suitable for laser engraving

The glass laser machine is capable of engraving almost any type of glass: cast, thermopolished, industrial, multi-layered, tempered and heat-strengthened, window and car glass, as well as mirrors and plexiglass, that is, acrylic.

When laser engraving mirrors, you can process both the front side and get a matte image on the surface, and engrave the back side of the mirror to remove the reflective layer.

Which glasses are difficult to engrave with a laser machine

Laser engraving of glass can be difficult if metals are present in the composition of the glass. For example, some types of crystal glass with a high lead content cannot be qualitatively engraved on a glass laser machine, since the appearance of microsheares and the formation of so-called “scales” during laser engraving of such glass is possible.

The appearance of these defects depends on the percentage of lead in the crystal. But in most cases, crystal can still be engraved if you choose the right modes of glass laser engraving.

Hand-blown glass is also prone to cracks during laser engraving, as it has a residual stress of the material. Therefore, we recommend setting minimum power settings and higher speed while working with products made of such material.

What other materials does the glass laser machine work with

The laser glass machine can also cut and engrave:

- wood materials: veneer, plywood, MDF, wood and others;

- plastics: PET, plexiglass, foam rubber, polyamide, polycarbonate, polypropylene, ABS and others (except PVC);

- textiles, leather and leatherette, fur;

And also can only engrave, but not cut ceramics and stone.

What kind of glass laser machine is needed

Our website presents a range of Wattsan laser machines for glass, as these machines have collected all the best functions and components for glass laser engraving. Therefore, let's consider the requirements for such equipment using the example of these machines.

The size of the working field of the glass laser machine

The maximum area of glass laser engraving depends on the size of the working field. The dimensions of the working field of glass laser machines can be from 200x300 mm to 2000x3000 mm.

If you need a small glass laser machine, pay attention to the desktop models Wattsan 0203 mini, Wattsan 0503 or Wattsan 6040.

Laser machine for glass Wattsan 0503

- Working field size: 500x300 mm;

- Power: 60W;

- Engraving speed: up to 700 mm/s.

- Price from 3265 €.

Check the other characteristics and the current price with Virmer managers: info@virmer.com; +31208082045. or on the website

If you plan to engrave large-format glass sheets, then Wattsan 2030 FlatBed is ideal for this task.

Laser machine for glass Wattsan 2030 FlatBed

- Working field size: 2000x3000 mm;

- Power: 100-120 W;

- Engraving speed: up to 500 mm/s.

- Price from 16747 €.

Check the other characteristics and the current price with Virmer managers: info@virmer.com; +31208082045 or on the website.

Frame and body of the acrylic laser machine

During the engraving, the laser head moves along the portal at high speed and in an instant changes the direction of movement to the opposite. For this reason, the glass laser machine experiences strong inertial loads, which cause vibrations that lead to poor-quality engraving.

A reliable frame and body help to neutralize these vibrations and extend the service life of the machine. To do this, a reinforcement frame is installed in Wattsan glass laser machines along the perimeter of the body.

The minimum requirements for the thickness of the laser machine body on glass are 2 mm. In Wattsan glass laser machines, the body thickness is 2.9 mm.

Power of the glass laser machine

The power of the glass laser machine should not exceed 120 watts, otherwise it will be difficult or even impossible to achieve high-quality engraving even at the minimum parameters.

Rotary device and lifting table of the glass laser machine

To engrave cylindrical products, you need to additionally purchase a rotary device. The rotary device can only be installed in those glass laser machines that are equipped with a lifting table function.

In the Wattsan 0503 and Wattsan 6040 glass laser machines, the table is lowered by 200 mm. The remaining Wattsan glass laser machines are divided into ST models — with a static table and LT models — with a lifting table.

For Wattsan ST machines, the gap from the laser head to the working field is 40 mm, and for Wattsan LT, the working table is lowered by 160 mm.

The number of working heads of the glass laser machine

To speed up the production process, some models of Wattsan glass laser machines are equipped with two working heads at once, which work simultaneously. Thus, at the same time, such a glass laser machine does twice as much compared to conventional machines.

An example of such a glass laser machine is Wattsan 1610 Duos ST.

Glass laser machine Wattsan 1610 Duos ST

- Working field size: 1600x1000mm;

- Power: 100-120 W;

- Engraving speed: up to 600 mm/s.

- Price from 9151 €.

Check the other characteristics and the current price with Virmer managers: info@virmer.com; +31208082045 or on the website.

Through hole in the body of the glass laser machine

The special body design of Wattsan laser machines for glass allows you to work with glass of any length, if it fits the width. This is realized due to a special technological hole at the level of the working field of the glass laser machine.

Mechanics of a glass laser machine

Wattsan glass laser machines operate on three-phase stepper motors. Compared with two-phase ones, they have a higher step discreteness, are more accurate, accelerate faster and perform braking - and this is critically important for quality. In addition, the motors on Wattsan glass laser machines are equipped with gearboxes that increase the engraving resolution to 2500 DPI and relieve the load from the motors themselves.

Potentiometer of a glass laser machine

All laser tubes have a minimum ignition threshold close to 10%. That is, at a lower power, not a single laser tube is ignited on any laser machine. The potentiometer allows for finer manual power adjustment, which is especially important for laser engraving of glass.

Safety

In Wattsan glass laser machines, all water hoses and tubes are separated from the electrics of the machine and are located in different sections of the housing.

Wattsan 6090 LT is one of the most versatile medium-format laser machines for glass with a lowered working table.

Universal laser machine for glass Wattsan 6090 LT

- Working field size: 600x900 mm;

- Power: 80-90 W;

- Engraving speed: up to 700 mm/s.

- Price from 5213 €.

For a detailed and up-to-date price, see the link or check with Virmer managers: info@virmer.com; +31208082045

All models of Wattsan glass laser machines are available on our website. If you need help in the selection of equipment and detailed advice, please contact our managers.

Advantages of working with Virmer:

- Detailed consultation from specialists in laser machines for glass;

- Showroom in the Netherlands, bring your materials for test work,

- Online demonstrations at a convenient time for you;

- Delivery and warranty for equipment;

- Pre-sale inspection and adjustment of the glass laser machine;

- Assistance in setting up, adjusting and start-up of a glass laser machine in your territory;

- Basic job training and advanced training from Virmer engineers;

- Warranty and post-warranty service.

- Lifelong informational support from Virmer managers.