It doesn't matter whether you need a professional machine or a consumer grade one – it's always unpleasant to waste hard-earned money. Especially if you have to run a business, a lot of urgent orders and a round–the-clock production load, and a recently purchased router machine which is the heart and center of your production universe, suddenly «goes down» for three days due to an unexpected breakdown.

It is important to buy a high-quality CNC router machine to avoid such problems. In this article, we will tell you in simple terms about how to choose a CNC router machine.

Read this article to the end and you will get to know the topic as deep as a technical specialist.

CONTENT

- What is the most important thing when choosing a CNC router?

- TOP CNC router machines

- Design features of a high-quality CNC router machine

- The bed of a CNC router machine

- Why is the gantry of a CNC router important?

- How to choose a spindle for a CNC router?

- Elements of kinematics and dynamics: motors, gearboxes, and guides.

- What affects the usability of the CNC router machine?

- Software

- Control System

- Working area of the CNC router machine

- Centralized lubrication system

- Tool sensor

- Aspiration

- Coolant

- Requirements for the supplier company

- Conclusions

What is the most important thing when choosing a CNC router?

According to the feedback from our customers, the most important features of a CNC machine include the speed of work, reliability, and a high-quality resulting product.

The speed of work equals economic benefits. The more products the machine manages to produce per unit of time, the faster it pays off.

The reliability indicator is also directly related to profit – the longer the router lasts and the less breaks during operation, the more profitable it becomes. Each breakdown is a production downtime and loss of money, as well as loss of business reputation if you disrupt the delivery timeframes of the product to your customers.

If we talk about the quality of the CNC router, it is determined by the accuracy of positioning and repeatability. Let us clarify these concepts.

The higher the repeatability and accuracy of positioning, the higher the repeatability and accuracy of the manufactured product.

Positioning Accuracy

Each point on the work field of the router has its own coordinates. Positioning accuracy means how much the actual coordinate reached by the machine matches the one specified in the program.

Repeatability

If we direct the machine to the same coordinate from different points of the work field, then each time we will get a slightly different result. This is unavoidable on any CNC machines due to mechanical errors. But a good CNC machine will have a low positioning error.

The processing accuracy of Wattsan CNC routers is 0.05–0.01 mm.

Engineers at the factory check and configure CNC router machines prior to dispatching them to our customers using the Renishaw Ballbar system, a high-precision equipment that analyzes repeatability, positioning accuracy and other operation parameters of the machine.

What determines the reliability, speed and quality of a CNC router?

All of the above qualities depend on the accessories and the main components of the machine, which include:

- a bed and gantry,

- a spindle and its parameters,

- elements of kinematics and dynamics: motors, gearboxes, and guides.

All components are interconnected and their correct selection relative to each other at the design stage of the CNC machine greatly affects its life, maintaining accuracy and quality of the resulting products at the proper quality level during the service life.

If the components are selected incorrectly and do not correspond to the level of the received load, over time a router may begin to produce poor quality products or, even worse, one of the machine components may fail.

Wattsan pays special attention to this issue, as it has been designing, testing and improving its CNC router machines for 20+ years. We understand how important each element of the router is, how the rigidity and quality of the frame and gantry affect the accuracy and why it is necessary to observe the alignment and perpendicularity of the guide axes and properly choose their accuracy class for the expected permissible loads.

Now let's talk about the qualitative characteristics of each main unit of the router, which affect the reliability, speed, and quality of work. And then we'll talk about other factors that significantly affect the convenience of work:

- control system and software,

- DSP Controller,

- worktable dimensions and features,

- centralized lubrication system,

- tool sensor,

- aspiration,

- lubricants and coolants,

- support, maintenance and other requirements for the supplier company.

It will be useful to know, regardless of a router manufacturer you decide to buy it from.

So, let's go back to the design features. The foundation, the body of the router is its bed.

Top Router Machines

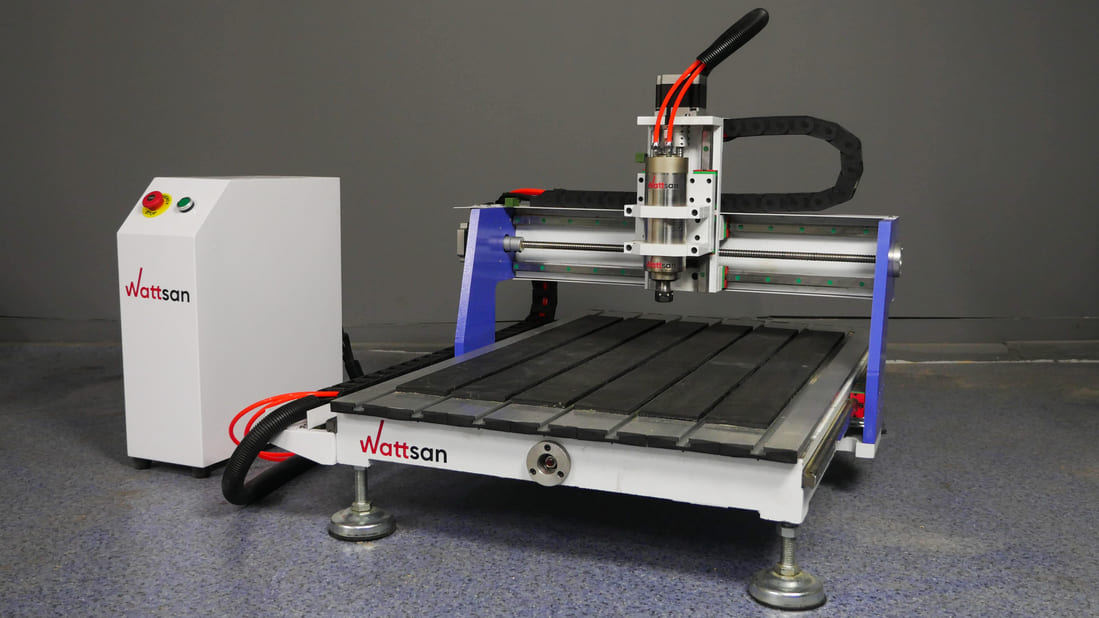

Wattsan 0609 mini

The best machine for starting your business or for a hobby. Suitable for making cutting boards, relief panels, design elements, small furniture, and children's toys.

It takes up little space, the spindle power is 1.5 kW, the size of the working area is 600x900 mm, the cost is about 3 600 €, check the current price here

Wattsan A1 1325

Lightweight professional-level machine. The size of the working area is 1300 by 2500 mm. It makes it possible to manufacture large products, such as doors, facades, furniture elements, and advertising structures.

The 3.2 kW spindle allows you to confidently mill any type of wood materials and various types of plastic.

The cost of this machine is about 7 320 €, check the current price here

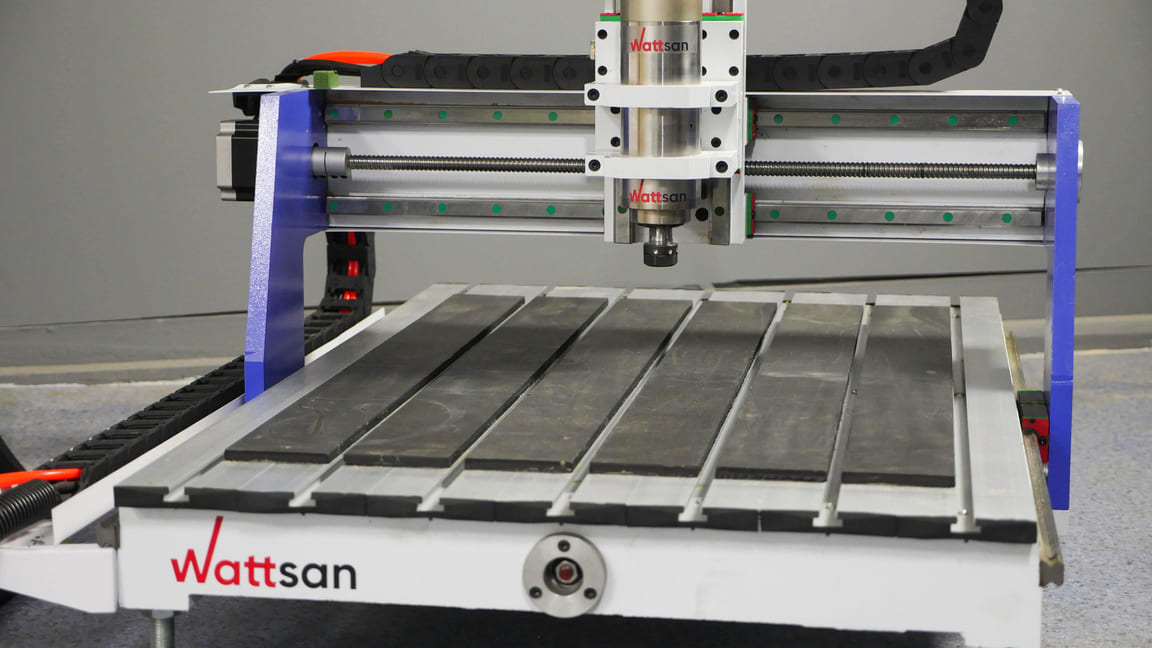

Wattsan M1 2040

A large-format machine for large-scale business. We have developed a series of M1 machines specifically for heavy round-the-clock loads.

Wattsan M1 2040 has a reinforced all-welded housing with a cross-section thickness of 10 mm, a gantry of increased rigidity allows the use of up to 12 spindles at the same time, planetary gearboxes are installed on the machine, the gantry clearance is 300 mm.

The working area is 2000 by 4000 mm. allows you to use a single sheet of almost any standard material without pre-cutting.

The 6 kW spindle cuts not only any plastics, wood materials and solid wood species, but also soft metals.

The price of the machine is about 14 380 €, check the current price here

Wattsan M3 1325

A machine with an automatic tool changing for uninterrupted manufacture. It has 8 cartridges for replaceable tools.

The size of the working area is 1300 by 2500 mm., the spindle power is 7.5 kW, servomotors with planetary gearboxes, Syntec 6MA control rack.

Price on request.

Design features of a high-quality CNC router machine

What should be the correct bed of a CNC router machine?

The machine frame should be as strong and stable as possible, because the router has to withstand high resistance of the material during operation, and this, along with the operation of the motors and the spindle, generates vibrations that can negatively affect the quality of work and the service life of the machine.

Less vibration results in the higher accuracy and repeatability.

In order to maintain accuracy, each frame of the Wattsan CNC routers is annealed and tempered in a special furnace in order to relieve metal stress. Without application of this technology, due to mechanical loads, the frame may deform over time and the machine will lose the alignment and perpendicularity of the guide axes and its entire structure.

Cast iron or welded frame – which one is the best?

Basically, there are two types of frame structures on the market: cast iron and welded metal. To date, we can say that cast iron is a thing of the past, since welded structures are in no way inferior to cast iron in quality, and in some aspects even supersede them. Moreover, the technology of manufacturing a cast iron bed requires settling at certain temperatures, sometimes up to 3 years, depending on the thickness.

The frame of Wattsan CNC routers is welded from rectangular steel pipes and sheets with additional stiffeners. The thickness of the cross-section of the bed walls is from 6 to 10 mm, depending on the machine model. This design eliminates vibrations and guarantees the preservation of the CNC machine geometry for more than 10 years.

Pay attention to vibration supports, they must be installed on a CNC router machine, as they help to additionally dampen vibrations.

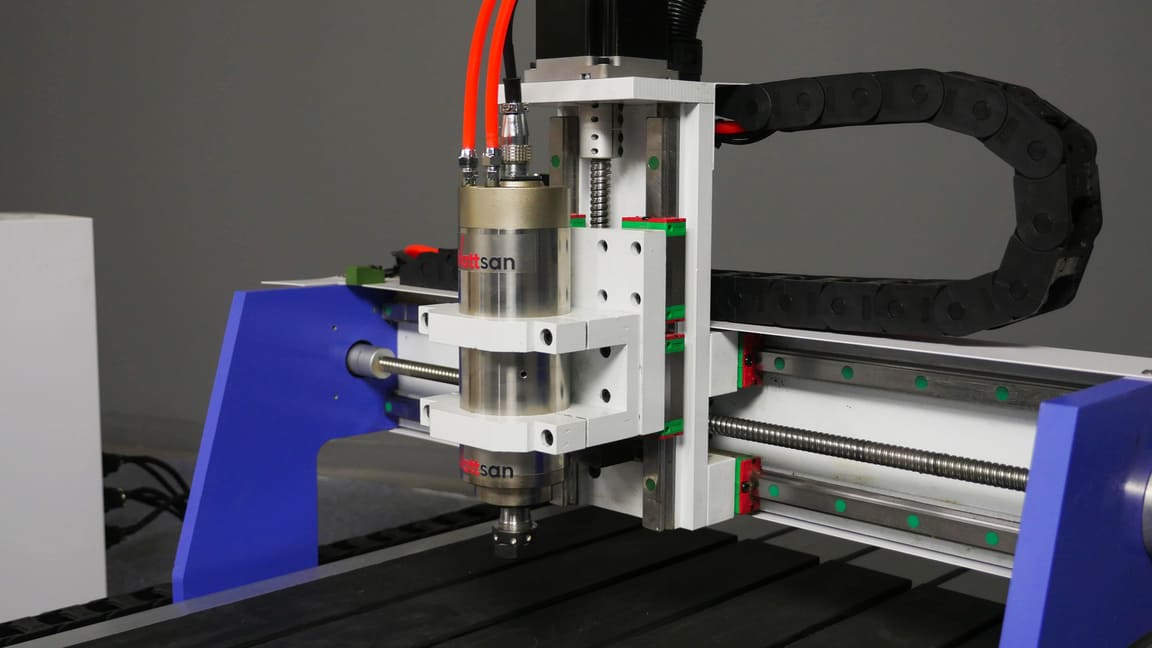

Why is the gantry of a CNC router machine important?

The gantry moves along the Y axis along the entire machine body and there is a spindle that moves along the X axis. Therefore, the quality of the gantry largely depends on the quality of the entire machine.

The gantry of a CNC router machine should in no case be made of aluminum due to the large weight of the spindle and, most importantly, heavy lateral loads during operation. The aluminum gantry just won't stand them.

Thanks to many years of experience, Wattsan engineers were able to achieve an optimal gantry design. We know how to simplify the design without affecting the maximum rigidity and reliability that are essential to the structure. For example, we have reinforced the side pillars of the gantry and the spindle mounting plate.

A reliable gantry is essential not only in terms of accuracy parameters, but it also secures an option of a more powerful spindle, which may be installed later, if required.

Wattsan M1 series CNC routers can be equipped with several spindles at once to speed up continuous production. Such gantries are designed for a maximum number of 12 spindles per gantry.

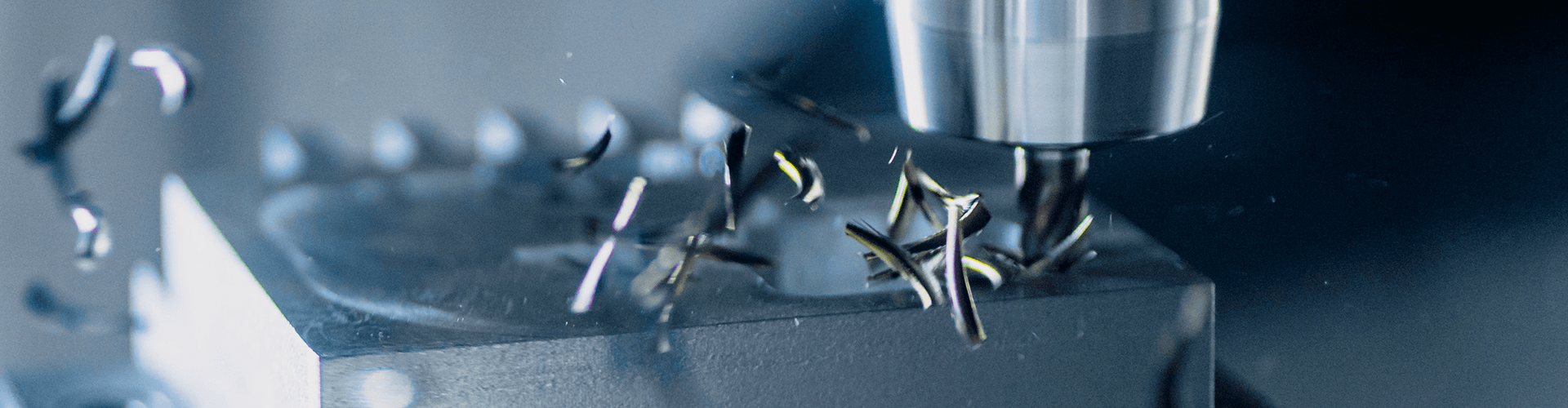

How to choose a correct spindle of a CNC router?

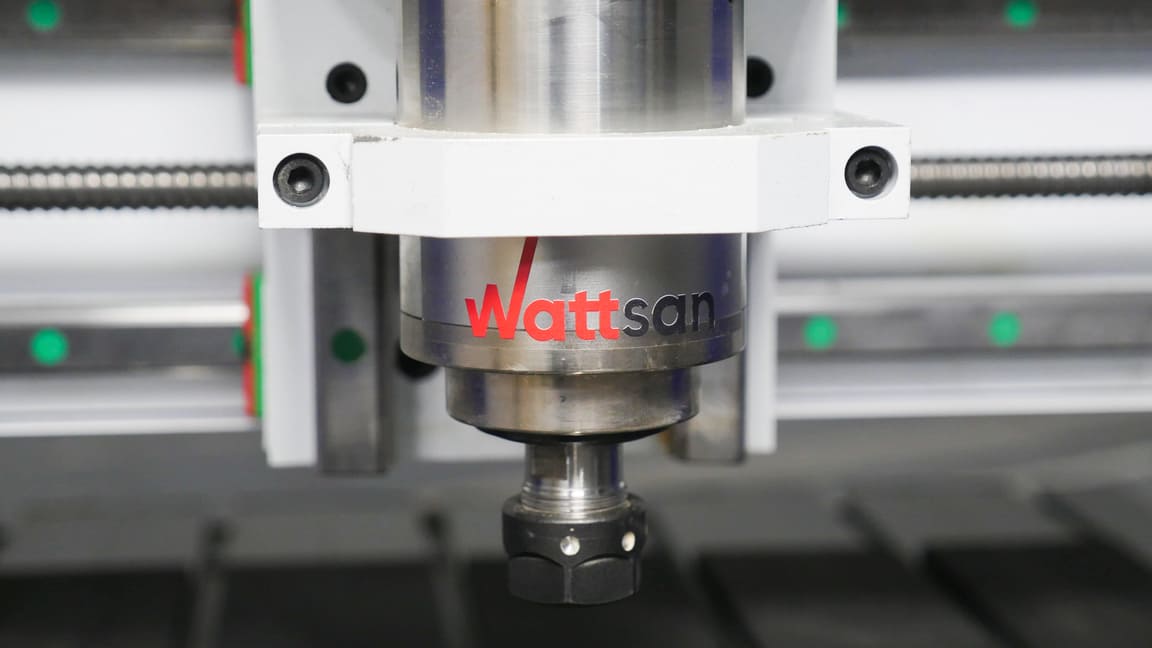

If the bed is a body of the machine, then the spindle is its heart. It is located on the gantry and is a motor with a collet chuck that clamps the machining tool.

The left and right movement of the spindle along the gantry is considered to be the X–axis, and the movement of the gantry itself together with the spindle along the machine body is the Y–axis. Also, the spindle moves up and down along the Z axis during operation.

The main task of the spindle is to transmit torque to the tool, which cuts the material layer by layer, rotating around its axis.

How much material and at what speed the machine can cut in one pass directly depends on the parameters of the spindle, as well as on the selected tool.

Basic Concepts

- Power – in fact, this is the energy consumed by the spindle, measured in Watts.

- Number of revolutions per minute is the speed of rotation of the tool, denoted as “rpm”.

- Feed is the speed of the spindle along the X, Y and Z axes, measured in millimeters per minute.

- Depth is how many millimeters the milling cutter plunges into the material along the Z axis.

- Torque is the force that the spindle creates to rotate the tool.

Now let's take a closer look at all the parameters.

Power

Frankly speaking, it is not entirely correct to consider power as an indicator of engine power, because the energy consumed is not always and not all of it gets transferred to the cutting force. Nevertheless, a more powerful spindle secures better performance, faster operation and wider possibilities when setting processing parameters.

If you want to work faster and have more processing capabilities, take a more powerful spindle.

If you need high-efficiency machining, then the required spindle power can be determined depending on your tasks:

- up to 1500 W – drilling and engraving only;

- 1500-3000 W – drilling, engraving and cutting of plywood, chipboard and fiberboard and plastics;

- from 3000 W – natural solid wood and hardwoods;

- more than 4500 watts – soft metal alloys and all of the above materials.

For industrial applications, it is impractical to take a spindle with a power of less than 1500 watts.

Determine in advance what materials you will work with and what type of processing you are interested in, so as not to lose with the power of your CNC router machine.

Let's consider the spindle parameters in detail.

Number of revolutions per minute

This indicator determines the feed you set, that is, what speed of movement along the X and Y axes your router can develop during operation. After all, the faster the CNC router rotates around its axis, the better it copes with the material during movement.

The rotation speed is programmed and depends on the material you work with and the selected tool.

Why is the material important?

Let's explain with an example. For the processing of wood materials, a high speed of rotation of the tool is required, spindles with an index of up to 24,000 revolutions per minute are most often used. For soft metals, on the contrary, a spindle with an index of 8000 to 13000 rpm is used.

Why is the tool important?

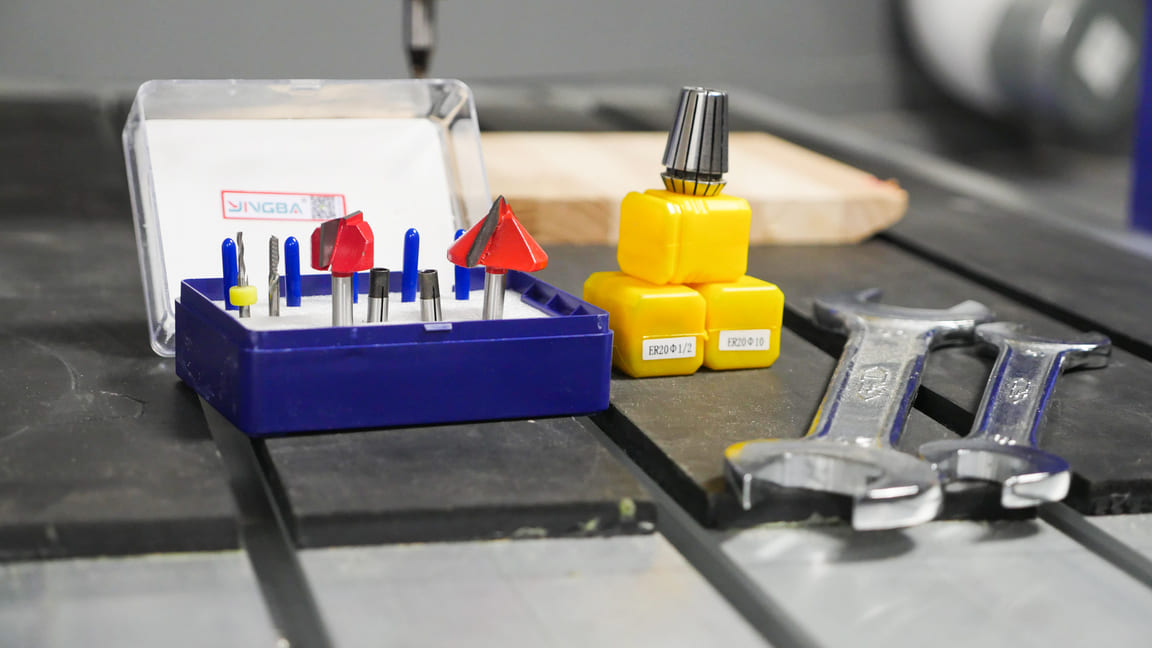

The cutting tool is made for specific tasks and specific materials, and it is designed for certain loads.

As a rule, any decent cutting tool manufacturer has a special program that makes it possible to calculate the cutting settings under specific initial conditions (material, type of processing, feed, allowances, etc.)

If you don't have any work experience, we recommend that you initially train on a cheap tool until you learn how to select parameters properly. Now let's discuss the collet chuck of a spindle.

Collet Chuck of Spindles

The collet is a chuck with a collet clip that reliably compresses the tool shank on all sides. This method of clamping helps to distribute the lateral loads that the tool is experiencing.

The collet chuck determines which tool you can use. As a rule, a more powerful spindle makes it possible to use cutters of larger diameters.

Wattsan machines use ER type collet chucks with a through hole and two clamping zones. The through hole allows the tool to be used with any length of the shank, and the double clamp along the axis maintains alignment with the spindle, despite the loads.

ER cartridges do less hopping compared to screw cartridges, and this is very important for extending the service life of the tool.

Below are the shank diameters according to the collet cartridges:

- ER11 – 7 mm,

- ER16 – 10 mm,

- ER20 – 13 mm,

- ER25 – 16 mm,

- ER32 – 20 mm,

- ER40 – 25 mm.

Tool Change

Working on a CNC router machine involves changing the tool during the transition from one material to another or the sequential use of several cutters in the process of performing one task.

The frequency of the milling cutter change depends on the product and can reach up to 10 times an hour or more.

Take the tool change time into account when you consider the benefits of purchasing a CNC router machine.

Fortunately, people tend to automate everything and make their work easier. Therefore, you can change the tool in different ways, depending on the configuration of your machine:

Manual Tool Change

Everything is simple here – you need two wrenches and strong hands that are not afraid of work. This is the most time consuming and labor-intensive way. With proper skill, it takes about 2 minutes for one tool changing operation. If there are 5 such operations per hour, you will lose about 17% of your working time.

For some tasks, manual tool change can take up to 25% of the working time.

Pneumatic chuck (semi-automatic tool change)

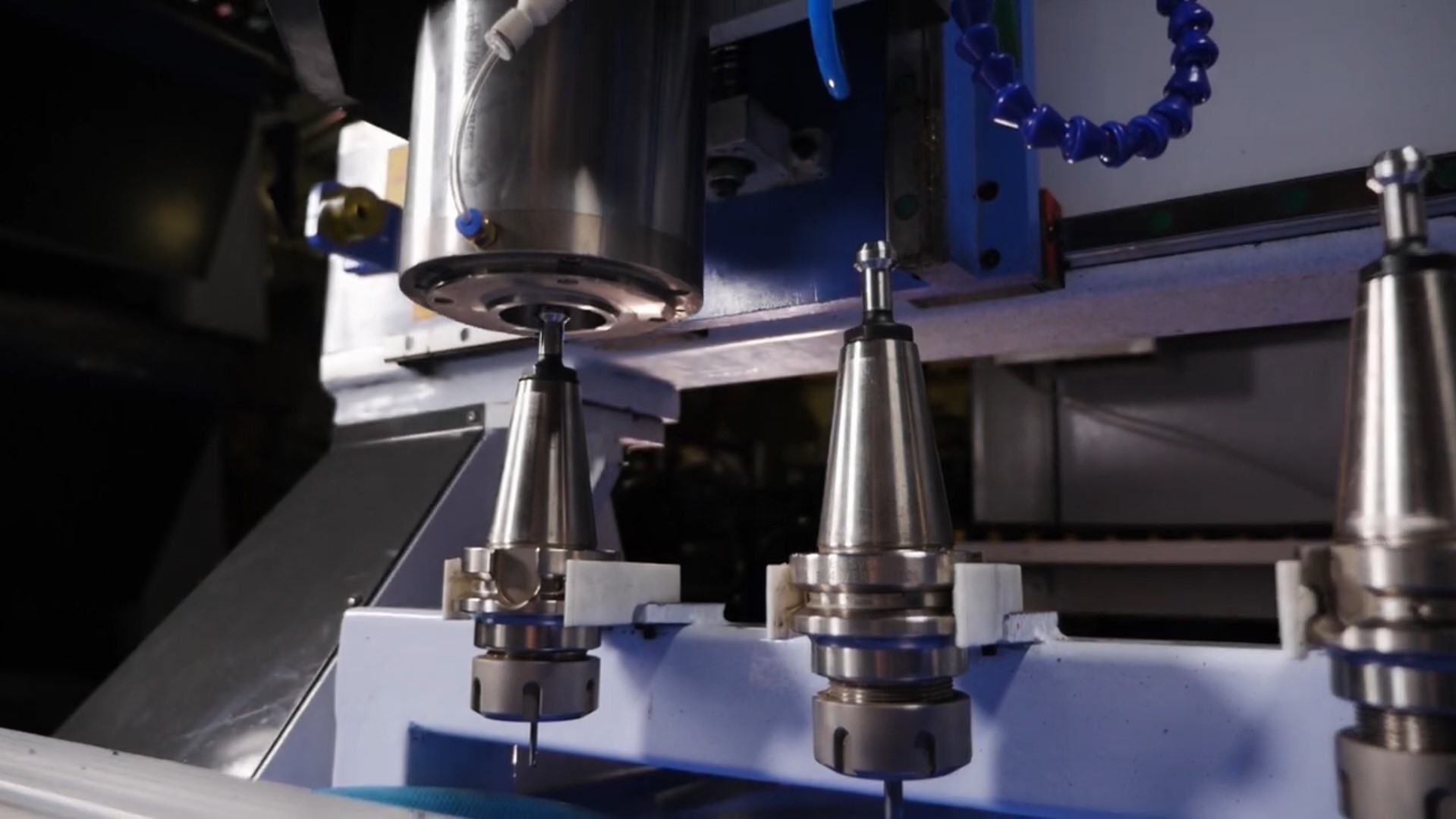

In the case of a pneumatic cartridge, you do not need to use wrenches every time. A spindle with pneumatics implies the presence of several replaceable cartridges, into which a working tool is installed in advance.

When the time comes, the machine operator presses a button on the spindle and easily removes the chuck. Then another chuck with the next tool is easily installed.

Changing a tool with a pneumatic chuck is faster and easier than manual, but it also requires direct human involvement, unlike automatic tool change.

Automatic Tool Change

It is an industrial solution that is increasingly gaining popularity. All you need to do is pick up the necessary tool in accordance with the processing program, install it in the tool magazine, specify the settings and run the program.

All tool change operations are performed automatically without the direct participation of the operator. This configuration of the machine greatly saves time.

An example of such a machine is the CNC router Wattsan M3 1325.

Multi-Spindle Machines

Another option to speed up the work process is to use several spindles at the same time. There are two options:

- Several tools on an air suspension are an alternative to auto-change, when several spindles with different tools are used on the same machine at once. For example, the Wattsan M4S 1325 CNC router: here each spindle uses a different tool, and the spindles work in turn.

- Several tools that synchronously perform similar work.In fact, it's just a few spindles that are attached to the gantry sequentially and each of them does the same work as the others. An example is the Wattsan M1 1313 S4 router machine – a great option to speed up the production of similar products.

Such solutions are used for large-scale continuous production and have a number of additional requirements for the reliability of the machine, due to the increased load on the gantry, bed, guides, and other elements.

The last but not the least important thing to take into consideration when choosing a spindle is its cooling system.

Spindle Cooling

During operation, the spindle heats up like any other motor, so it requires high-quality cooling. There are two types of cooling:

- Air cooling

The main advantage of this type of cooling is its lower cost. But there is also a number of disadvantages:

- Air cooling is very noisy,

- This type of cooling is not suitable for working with metals, even soft ones, such as aluminum, brass or copper, since the spindle heats up a lot more at low speeds.

- Liquid cooling

Liquid cooling works quietly and more efficiently, it is suitable for working with soft metals. Cons:

- It's more expensive,

- It is a more complicated system, and a chiller or a pump is needed for work.

Most often, ordinary distilled water is used as a coolant, which must be changed when gets contaminated.

We strongly recommend using a chiller, since working with a CNC router machine is very dusty, and dirt and dust should not get inside the spindle, otherwise it will quickly overheat and may become unusable.

The advantage of the chiller is that it always shows the current temperature, has a closed circuit and active cooling, unlike a pump. Also, in case of any malfunction, such as hose clamping or exceeding the critical temperature, the chiller will give a warning signal.

With a chiller, the spindle will definitely last longer than with a pump.

Which type of spindle cooling to choose depends on your tasks, as well as on your budget.

This concludes the section about the spindle. Now let's move on to the elements responsible for movement.

Elements of Kinematics and Dynamics

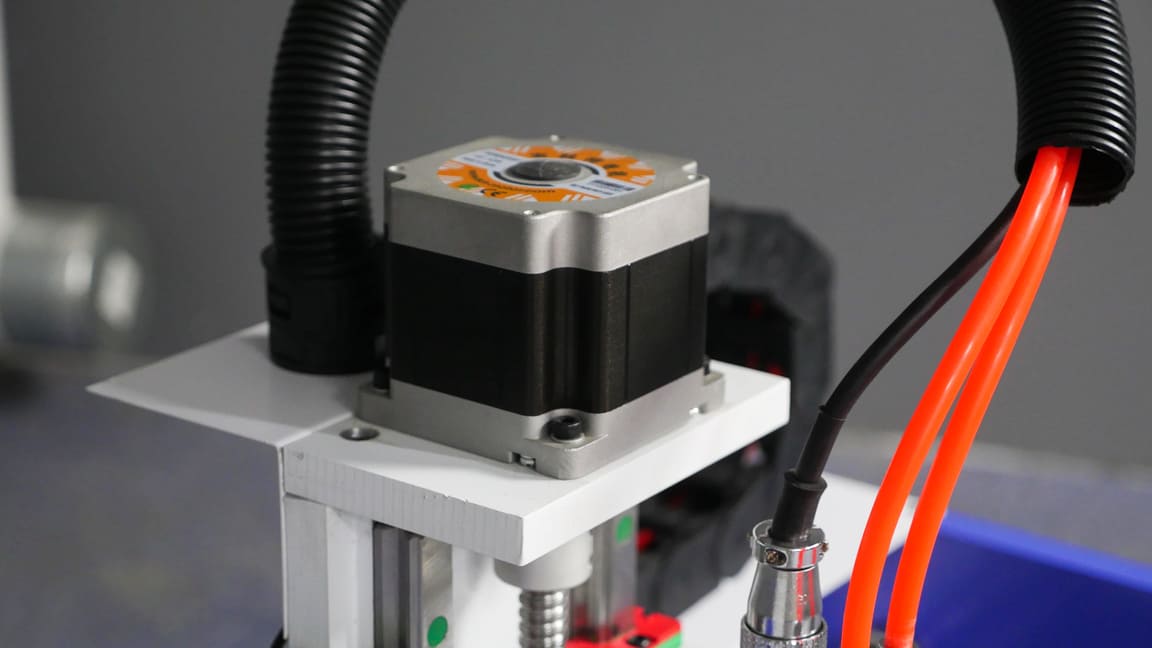

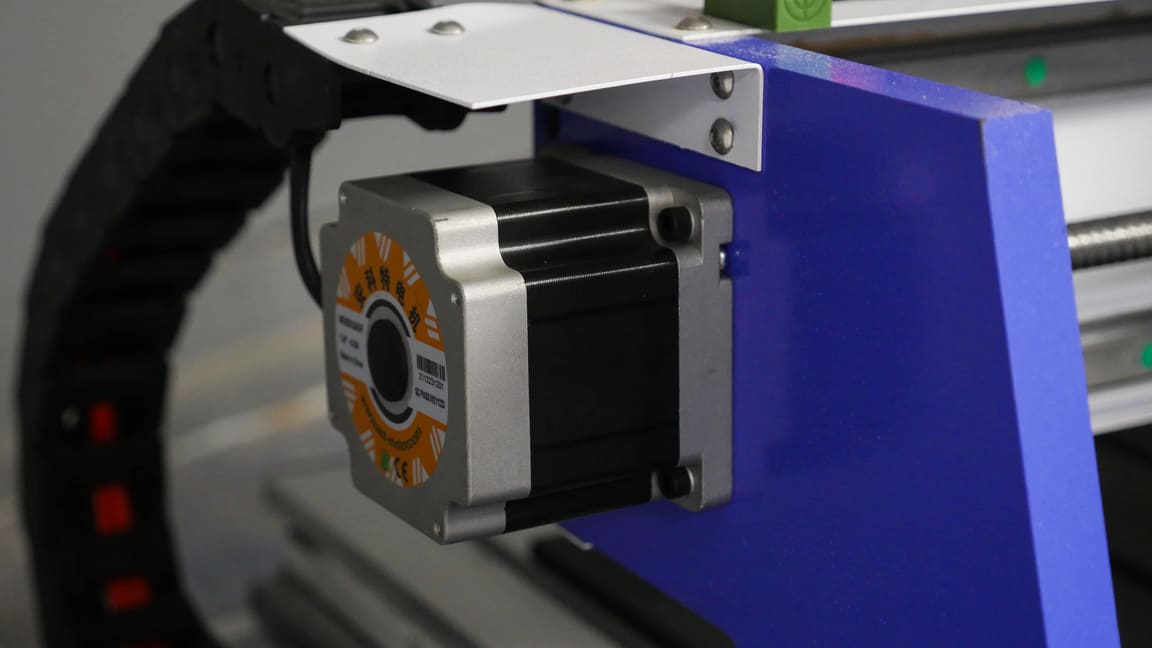

Motors of the CNC Router Machine

The CNC router uses motors to move along the X, Y, Z axes. In all such systems, stepper motors are most often used, but sometimes it can also be a servo. What's the difference?

Stepper Motors

The stepper motor receives commands in the form of impulses. The engine translates this information into a discrete value by which it needs to rotate. This rotation through the gearbox goes to the movable part of the machine, which sets it in motion. The minimum unit of rotation is called a “step".

How many degrees the engine rotates in one step is called its coefficient. For example, on Wattsan machines there are stepper motors with a coefficient of 1.8 – this means that in one step the engine rotates by 1.8 degrees, and it makes a full 360-degree rotation in 200 steps. This indicator makes it possible to achieve accuracy in movements up to hundredths of a millimeter.

The more steps the engine can take in one full 360-degree rotation, the more accurate its movements are.

Despite the fact that stepper motors do not have feedback sensors, if properly configured, they will serve you for a long time without failure and will allow you to achieve high accuracy of movement.

Servomotors

Servomotors are electric motors and therefore they are more precise, smooth and at the same time fast. Thanks to the encoder, it is possible to calculate the engine speed more accurately when driving.

Servomotors are faster, more accurate and quieter, but more expensive.

A big plus of servomotors is that they do not skip steps, since the encoder has feedback from the drive. And also, servomotors give less vibrations and work quieter. However, they are much more expensive than stepper motors.

Which engine should I choose for my CNC router machine?

In most CNC router machines, there is no need for servos. Yes, they are much faster, but all the work on the router is relatively very slow, so such engines are considered an excess, since they simply increase the cost of the machine, without giving the necessary advantages.

Servos are important for a CNC router only for a machine with automatic tool change, since in this case a high speed of movement at idle is required.

For example, the Wattsan A1 and M1 series router machines are equipped with NEMA 34 stepper motors. Servomotors are installed on self-changing tool machines. There are also hybrid stepper motors, for example, as on the Wattsan M4S 1325 machine.

Hybrid engines also have feedback and other advantages of servomotors, but they are not as expensive.

We adhere to the principle of sufficiency in the design and manufacture of our machines. Therefore, we choose the highest quality components for specific tasks and loads.

In addition, when choosing engines, it is important to consider the gearbox.

Which engine gearbox to choose and what does it affect?

We have already talked about the coefficient of the engine: if we do not have enough steps to get exactly to the required preset value, or vice versa – we have extra steps to perform a certain task, then the gearbox will help us.

The gearbox secures splitting of the motor pitch, thus increasing the resolution of the work and its accuracy. In addition, the gearbox increases the torque and simultaneously removes the load from the stepper motor, extending its service life.

Depending on the workloads and modifications, Wattsan machines are equipped with belt or planetary gearboxes.

Belt gearboxes have a very simple design, while performing their function well. If necessary, they can be easily replaced, especially since they are very cheap.

Planetary gearboxes have higher efficiency and large gear ratios, are trouble-free in operation, but at the same time they are much more expensive.

The reduction coefficient of belt gearboxes on Wattsan machines is 1.5, the coefficient of planetary gearboxes is 1.7.

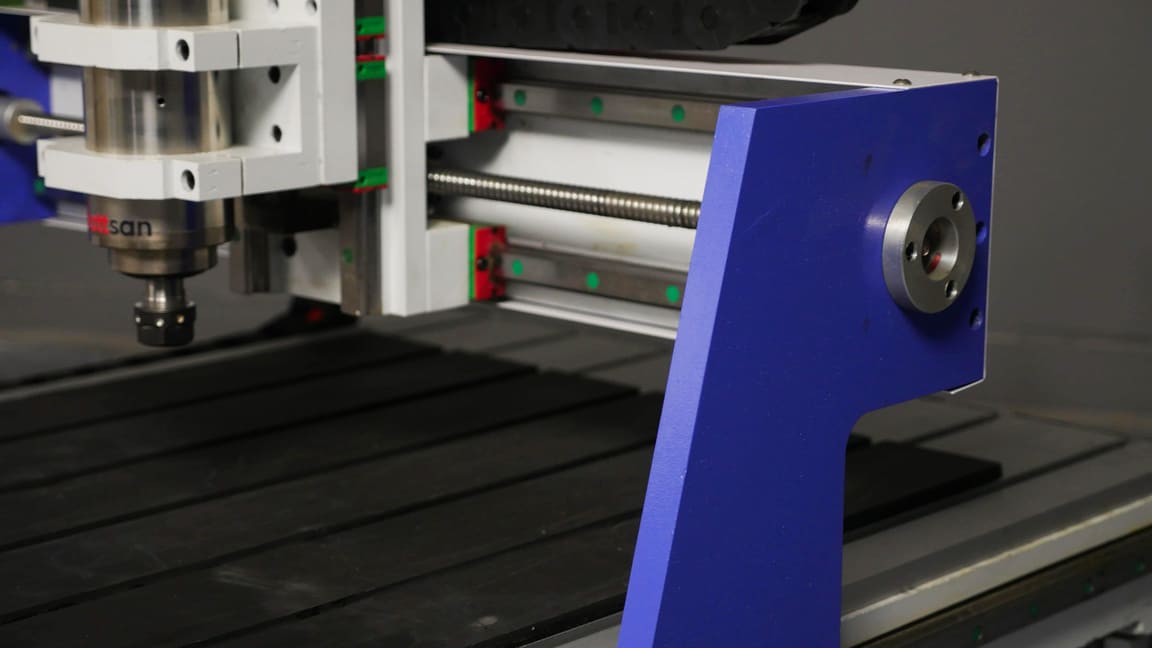

Guides

All moving parts of the machine move along the guides along the X, Y and Z axes. These are elements that serve to preserve the accuracy of all movements.

We have long abandoned all types of guides, except rail. In our router machines, we give preference to the most reliable and affordable brands in the world – HIWIN and PMI. These brands have proven themselves well and have a long service life due to the low coefficient of friction and thoughtful design.

The width of the guide for the router machine should be from 15 to 25 mm, depending on the size of the working area.

If the guides are not selected according to the loads, then over time, the backlashes and a decrease in accuracy and repeatability of work is inevitable.

On Wattsan machines, even on the youngest desktop models, rail guides are installed on all axes. It is important to us that our routers maintain their accuracy and quality even after decades of continuous operation.

In order to maintain the alignment of the guides and maintain it throughout the life of the machine, it is necessary to install them on a perfectly flat surface. To do this, after annealing the bed on Wattsan machines, the milling of the platform for rail guides and helical racks takes place using a high-precision robot

It is impossible to guarantee the high quality of the machine operation without preparing a perfectly flat platform for the installation of guides or a helical rack!

We have analyzed the main design features that affect the quality of the machine. Now let's talk about the convenience of work and other important aspects that you should know before you buy a CNC router.

What affects the usability of the CNC router machine?

Software

In order for the machine to understand what it needs to do, it is necessary to create a special file – it is called a “control program”, it is also called a «CNC machine cutting file» or simply a «layout».

There are many layouts available on the Internet free of charge, they can be used for training and practicing your skills.

Software for creating control programs are divided into CAD and CAM:

CAD (Computer-Aided Design) – programs in which parts are designed and vector drawings are created. Such a drawing can be created even in CorelDRAW, but you can run it on the machine only with the help of a CAM-program;

CAM (Computer-Aided Manufacturing) – programs that translate vector drawings into machine-readable G-code. Here, not only the coordinates of the movement of the spindle with the tool are set, but also the type and size of the tool itself, the number of revolutions, feeding, deepening, material type and other settings.

Often, programs for working with a CNC router machine are complex CAD/CAM systems in which you can both design drawings and configure and run a control program.

Examples of such CAD/CAM systems are Vectric Aspire, ArtCAM, SolidWorks, Autodesk Inventor, Vcarve, SheetCam and many others.

Which program to use depends largely on your skills – use the one you are well versed in. However, if you are already familiar with one of the programs, then it will not be so difficult for you to understand the other.

If you are starting from scratch and it is difficult for you to decide, you can choose Vectric Aspire, which is one of the most popular editors with a wide range of functionality, which is easy to understand.

Also, to begin with, you can try several programs at once and choose the one that is the most convenient for you.

Control System

The control system receives and decrypts the G-code and gives commands to the machine. There is a huge number of them, i.e. NC Studio, Mach3, Moriseiki, Syntec, Weyhong, Fanuc, HAAS, Seikos, Heidenhain, DSP controllers, etc.

The control system may consist of:

- A special application, for example, NC Studio or Mach3, which needs to be installed on a separate computer,

- The DSP controller is a control panel connected to the machine. During operation on the controller, you can adjust the parameters that are set in the program. You can run tasks from a USB drive, you do not need a separate computer for the control system.

- A full-fledged rack-type computer, such as Syntec or Weyhong is designed to control more complex processes, such as tool change, multi-axis machining, pneumatic seals, etc.

Which system would be the best is a controversial question, because each specialist finds certain pros and cons in each of the control systems. In our experience, for small systems, a DSP controller is definitely more convenient than a separate computer with a program. If you choose from NC Studio or MASN3, then we prefer the first option.

For more complex CNC router systems, it is simply impossible to do without a fully functional control rack.

Now let's talk about the working area of the machine in the context of its usability.

Working Area of the CNC Router Machine

The main parameters of the working area of the machine are the size of the working area and the method of fixing the workpiece.

Size of the Working Area

The size of the working area is one of the most important parameters affecting the work. By size we mean both the length and width, as well as the height of the workspace.

Length and Width (X and Y axes)

The size of the material that you will process depends on this parameter. It is very convenient when a standard sheet of material is immediately placed on the working area of the machine. Otherwise, the material has to be additionally cut. And this not only takes time, but it also requires additional space in the workshop.

The length and width of the working field determines the maximum size of the final part or product that you can produce.

Productivity also depends on the size of the working area along the X and Y axes – it takes from 10 to 15 minutes to change a sheet of material between treatments. And since with the large size of the working area you need to change the material less often, then you significantly gain in time.

Height (Z axis)

The range of movement of the spindle along the Z axis determines what maximum thickness of the workpiece you can process and whether you can connect a rotary device to process cylindrical products such as balusters, furniture legs and figurines.

The recommended spindle stroke height for using a rotary device is 300 mm. It is possible to use a rotary device with a gantry clearance of 200 mm, but in this case the thickness of the product will be severely limited.

Wattsan A1 series CNC router machines have a spindle stroke height of 200 mm, and M1 series machines have a stroke height of 300 mm.

Fixing the Workpiece

Milling of any material requires reliable fixation on the working table. There are two main options: mechanical fastening and vacuum clamping.

Mechanical Fastening

Most standard router machines have a table that consists of special T-shaped slots with which you can fix the workpiece or material by mounting bolts or clamps.

Make sure that the cutting tool does not collide with the clamp or mounting bolt during operation!

Mechanical fastening is better suited for materials of large and medium thickness, since when using this method, thin material is difficult to completely align in the middle of the table, especially on large working areas.

Vacuum Clamping

It is a special design of the working area, which, with the help of a pump, pulls the material up to the table through special holes.

The vacuum table is ideal for thin materials and levels them over the entire area. This type of attachment greatly accelerates the installation and disassembly of the material on the table.

The vacuum table does not exclude the use of mechanical fixation if necessary. For example, when working with thick materials.

Such a design divides the working area into 4–8 zones that can work independently. The whole table is divided into small square grooves, along which you can limit the processing area with a rubber cord to match the size of a workpiece.

Centralized lubrication system of a CNC router machine

In order not to lubricate each movable unit of the machine manually, it can be equipped with a centralized lubrication system. It can be manual or automatic.

The manual lubrication system has a special lever that must be pressed to carry out the lubrication process.

The automatic lubrication system performs this work automatically, moreover, it can be set by timer. You will only need to top up the oil in a special tank when it runs out.

A centralized lubrication system, regardless of whether it is manual or automatic, significantly saves time on machine maintenance.

Tool Sensor

Before starting work, the machine must be set to a zero point. The tool sensor simplifies this task, allows you to do it automatically and adjust as accurately as possible.

Not equipped with a tool sensor which is a mandatory accessory on machines with automatic tool changing.

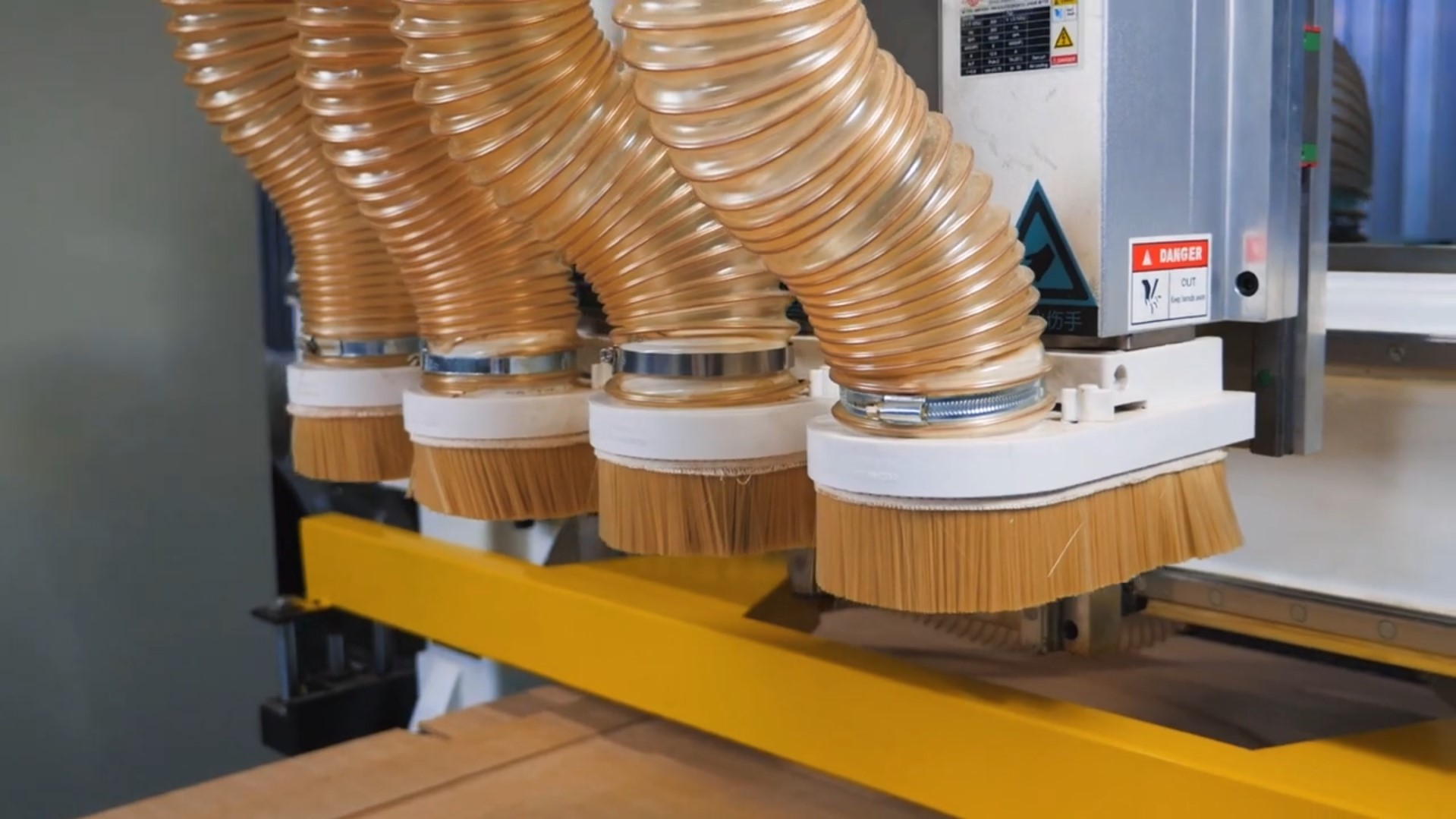

Aspiration System

The aspiration system is an industrial stationary vacuum cleaner with a corrugation and a brush, which are connected to the spindle and directly to the working tool. This system makes it possible to suck out chips and dust during operation into a special bag.

Working without aspiration can lead to problems with the skin, mucous membranes and respiratory organs.

Advanced aspiration systems not only clean the workplace, but also filter the air.

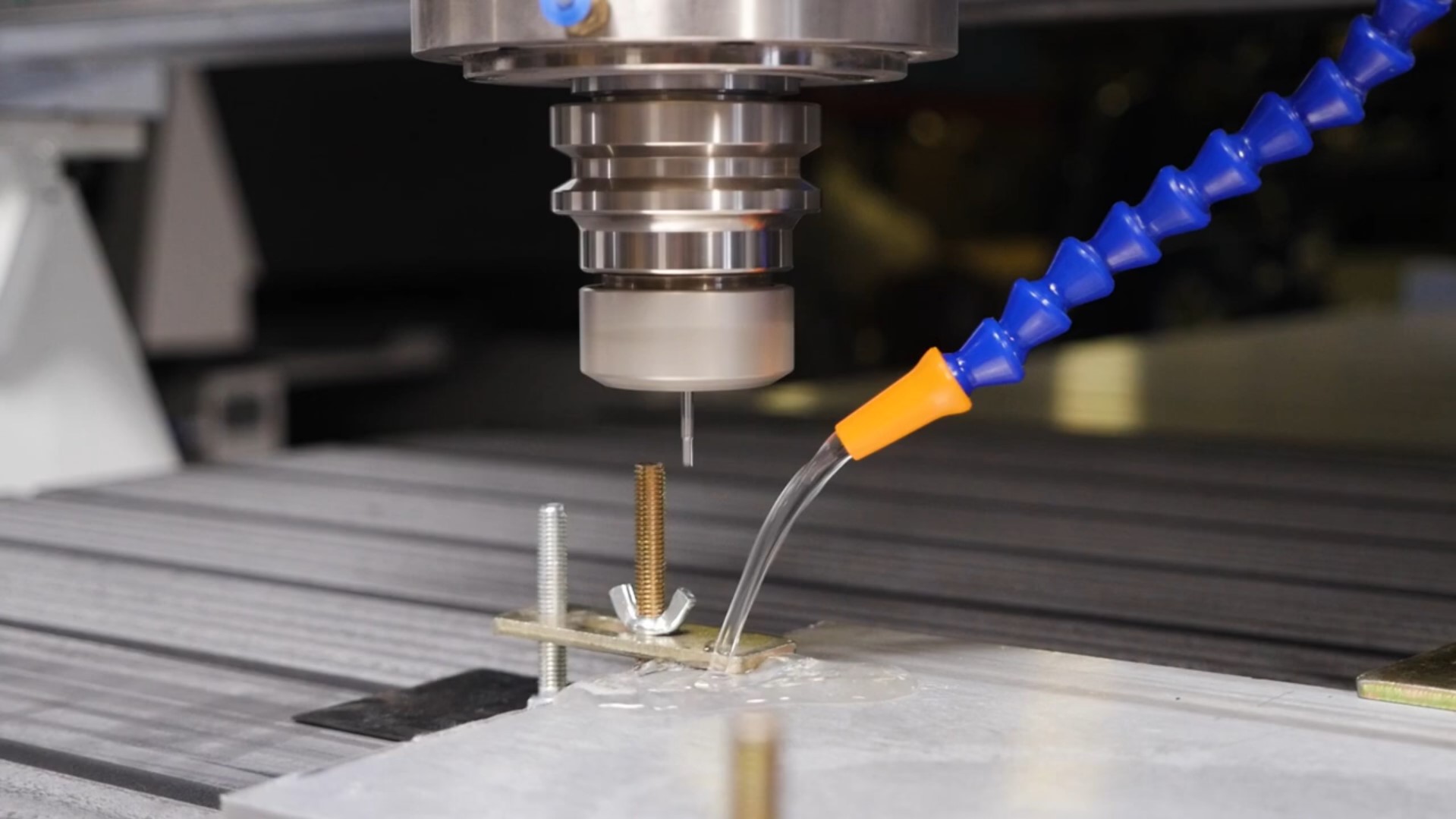

Coolant

Coolant (Lubricating and Cooling Fluid) is necessary for working with metals, so as not to overheat the tool and the material itself.

A special liquid (water, oils or emulsions) is supplied to the milling point through the nozzle. Further, this liquid is discharged along the gutters and along the machine body into the pump, where it is filtered and again fed to the work area as in a closed loop.

Support, Maintenance and Supplier Requirements

A supplier company is as important as the aspect of quality. Here are some tips that you should pay attention to when choosing an equipment supplier:

- Even at the first stages of communication with a representative of the supplier company, you will be able to assess their level of competence;

- Always ask clarifying questions. You should be alerted by unclear wording and evasive answers;

- Be sure to sign a contract with the supplier company;

- Look for a company that can help you with delivery, commissioning and training;

- It is better to choose a supplier who is able to provide warranty and post-warranty service.

Wattsan's moto is “We Work for Clients of Our Clients". This means that it is important to us that you can offer the end consumer the highest quality product, whether it is children's toys, decorative products, advertising structures, or furniture.

We make equipment that is capable of delivering a high-quality product. This means that your customers will come back to you and recommend you.

Conclusions

It is important to understand that when buying a CNC router machine, you pay not only for the equipment itself, but also for its safety margin, further maintenance and possible repairs.

And now, as it seems, not many are tempted by cheap machines. Although this still happens. But now you know what to pay attention to and how to choose a high-quality machine.

The other side of the coin is too expensive equipment. A high-quality router machine does not have to be too expensive, because the main thing is its competent design, the ratio of components relative to each other and the choice of the best possible equipment at the best price.

Expensive brands, although they are holding the bar high, add a large margin for their name.

A properly designed machine with a price of 8000 € will work at the highest level for the same 10 years as a machine for 20,000 €.

Wattsan designs its machines guided by the principle of sufficiency – twenty years of experience allows us to choose the best of the necessary equipment so that our customers do not overpay.

We hope this article was helpful for you. Now you know what you need to pay attention to when choosing a CNC router machine.

If you need a detailed consultation, please contact our managers.

Q&A

What should I pay attention to when buying a CNC router machine?

According to the feedback from our customers, the most important features of a CNC machine include the speed of work, reliability, and a high-quality resulting product.

How to choose a right spindle for a CNC router?

The material size and the speed at which the machine can cut in one pass directly depends on the parameters of the spindle, as well as on the selected tool.

The parameters of the spindle that need to be correlated are power, number of revolutions per minute, feed, deepening, and torque.

How much does a good CNC router machine cost?

A properly designed machine with a price of 8000 € will work at the highest level for the same 10 years as a machine for 20,000 €.

So, the average price for a machine with a working area of 1300 by 2500 mm, which makes it possible to produce large products, will be about 8250 €.

Which CNC router machine is the best?

A high-quality router machine does not have to be too expensive, because the main thing is its competent design, the ratio of components relative to each other and the choice of the best possible equipment at the best price.

What is the best novice level CNC router machine?

Wattsan 0609 mini is the best machine for starting your business or for a hobby. Suitable for making cutting boards, relief panels, design elements, small furniture, and children's toys.

It takes up little space, the spindle power is 1.5 kW, the size of the working area is 600x900 mm., the cost is about 4 549 €, check the current price here.