High-tech laser equipment is becoming more affordable and today anyone can buy a laser cutting machine for home. The laser cutting machine is useful for hobbies, home workshop and even for starting your own business right at home.

In this article, we will look at how to choose a laser cutting machine for home, discuss the advantages of home laser cutting, tell you what materials a laser cutter for home works with, what can be made with it, and also share tips on laser cutting at home and tell you about the typical mistakes of those who decided to purchase a laser cutting machine for home.

How to choose a laser cutting machine for home

First you need to understand what you want to do and why you need a laser cutting machine at all. If you have already made it clear and decided to take the machine for specific tasks, it will become clear what kind of material you plan to work with. Having decided on the material, its size and thickness, you will be able to understand what the power of the laser tube is needed, the size of the working field and other parameters.

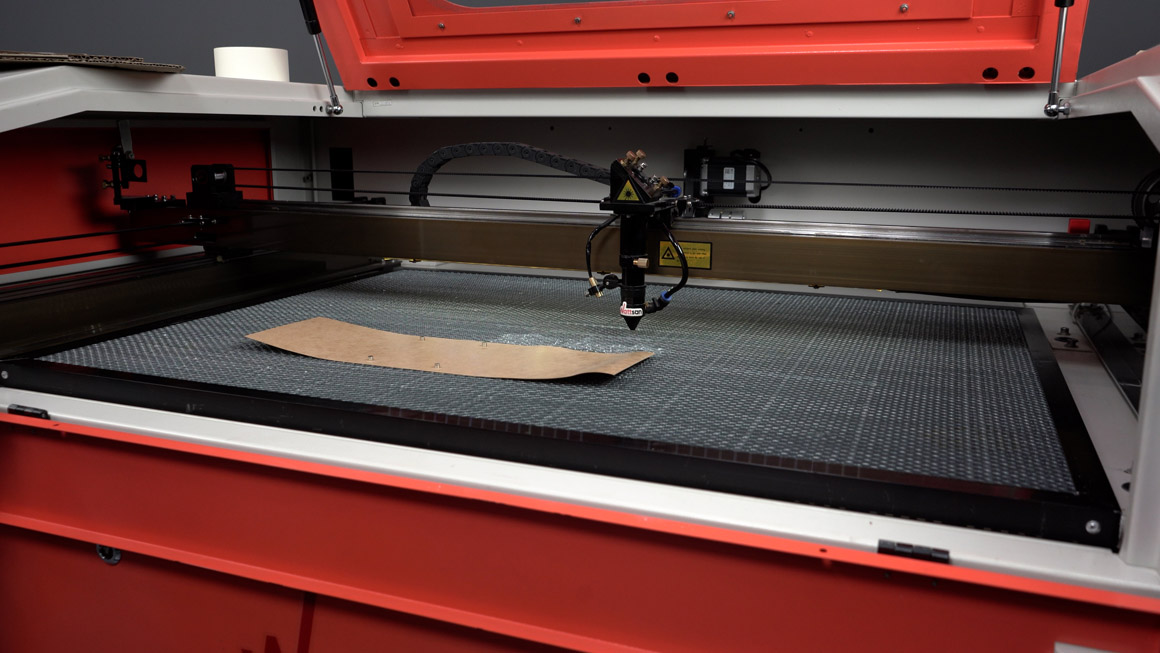

Dimensions are one of the main criteria for choosing a laser cutter for the home.

Dimensions and working field of a laser cutter for home

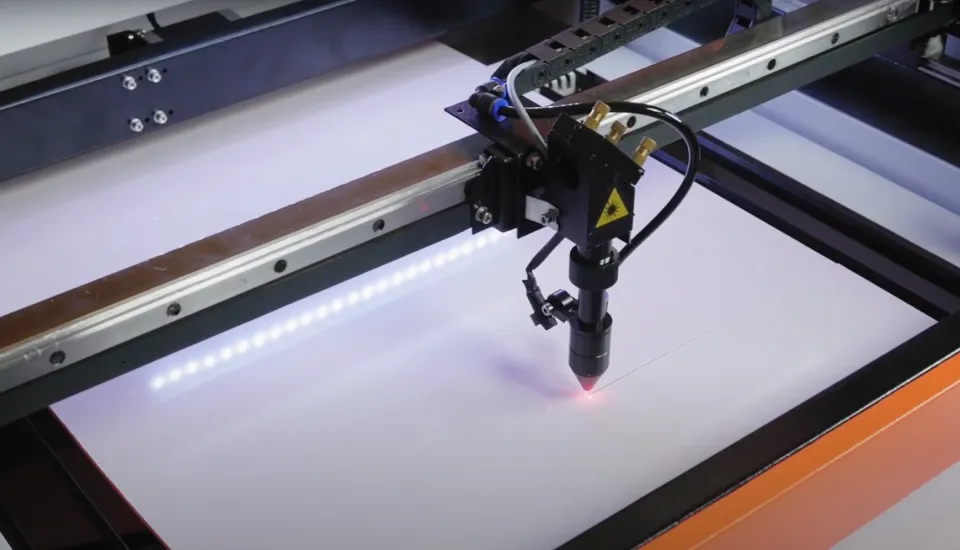

The working field is an area of certain dimensions where laser cutting takes place.

Depending on the size of the working field, laser cutting machines for the home are divided into three main categories:

- Desktop small-sized machines (200x300, 500x300, 600x400 mm),

- Floor-mounted medium-format machines (600x900, 1200x900 mm),

- Floor-mounted large-format machines (1600x1000, 2000x3000 mm).

Most often, when people want to choose a laser cutting machine for home, they stop at small-sized desktop machines, such as Wattsan 0503 and Wattsan 6040. The dimensions of the working field are 500x300 and 600x400 mm, respectively.

You can also pay attention to medium-format laser cutting machines for home, if you have a separate room, basement or garage for a workshop, or there is simply enough space in the house for this. The best solution would be a Wattsan 6090 LT with a lifting table with a working field size of 600x900 mm or even Wattsan 1290 LT with a working field size of 1200x900 mm.

However, if the area allows, then nothing prevents you from buying a large-format laser cutting machine. The next choice parameter is the power of the laser cutter for home

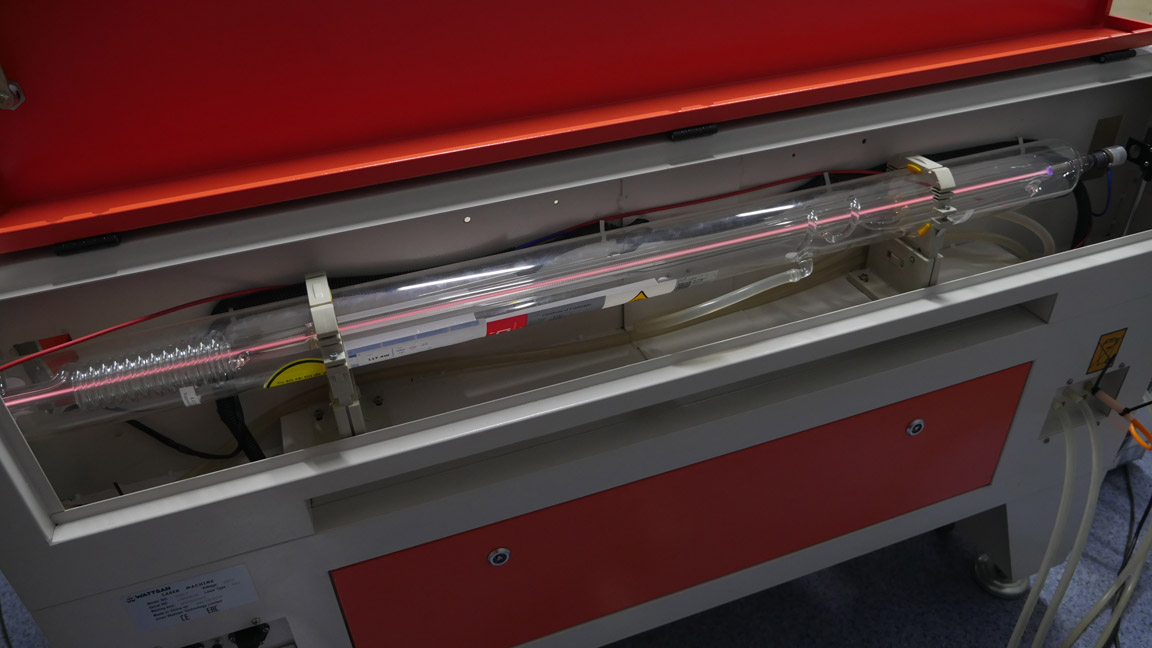

Power of the Laser Cutter for Home

The higher the power of the co2 laser machine, the thicker the material it will be able to cut through. Laser cutters for the home can be divided into three categories by power:

- Low-power: up to 60W;

- Medium power: from 60 to 100 watts;

- High-power: more than 100 watts.

There are special formulas that allow you to understand what the maximum thickness of the laser cutter for home will cut. For example, 10 watts of power is consumed for every centimeter of plywood. That is, a laser cutting machine with a power of 60 watts will cut 6 mm plywood.

Frame and housing of the laser cutting machine

One of the key characteristics of a laser cutter for the home, which affects its service life and quality of work, is the housing. The quality of the housing depends on how stable the machine is, that is, how well it is able to neutralize vibrations during operation.

The main requirement for the frame of a laser cutting machine is the presence of an additional internal frame that strengthens the structure.

The main requirement for the housing is that its thickness should be more than 2 mm. For example, Wattsan home laser cutters have a housing thickness of 2.9 mm.

Laser Cutting machine motors

Laser cutting machines are equipped with two- or three-phase motors. The design of 3-phase motors is such that with the same dimensions they have more power.

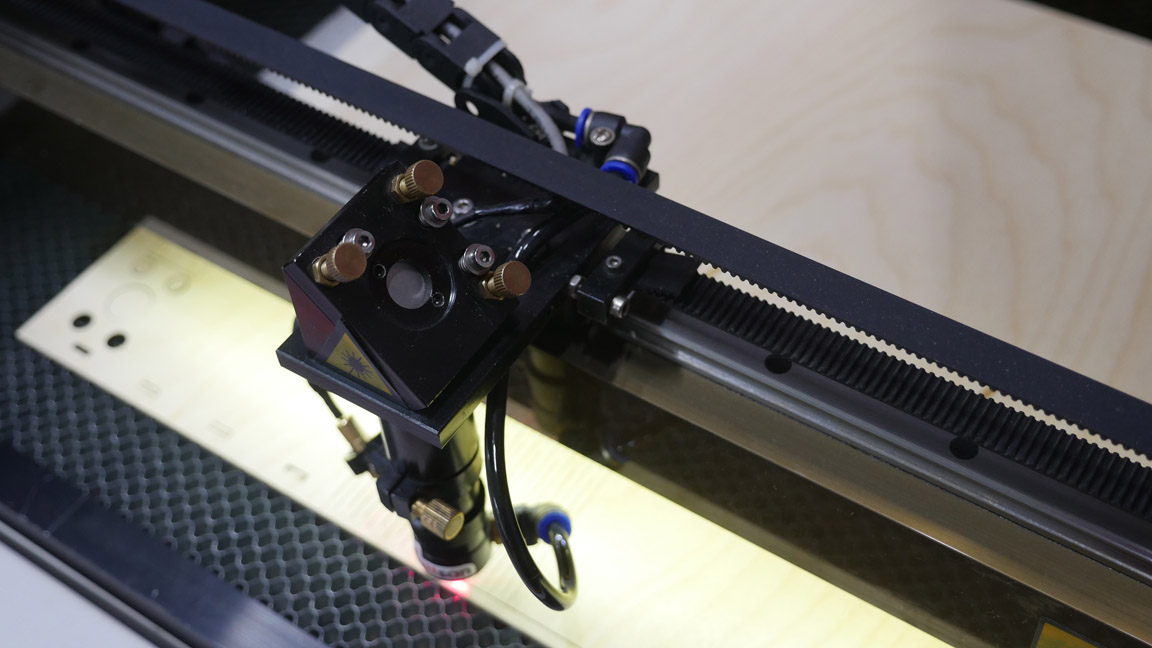

Guides of Laser Cutter for Home

To preserve the quality and accuracy of work, it makes sense to pay attention to laser cutters for home, equipped only with rail guides. Cylindrical guides are considered to be of lower quality, but cheaper. An option that is definitely not suitable for a laser cutting machine is roller guides.

Additional features of the laser cutter for home include a rotary device, a lifting table and a through design of the working field.

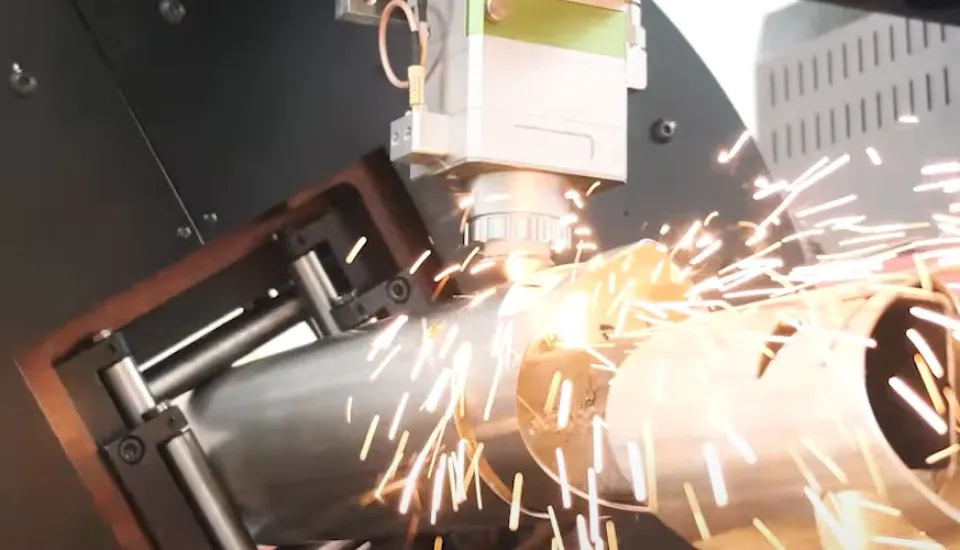

Rotary device for laser cutting machine

Some machines have the ability to connect a rotary device for processing cylindrical workpieces and objects. For example, you can engrave glasses or cylindrical packaging.

Lifting table of laser cutting machine

The lifting table allows you to lower the working field to work with thick materials or to install a rotary device. This can expand the range of possible goods and services produced.

Through table of Laser Cutter for Home

Some laser cutting machines have a special through hole at the level of the working field. This allows you to stretch materials of any length, so you can work with larger materials.

The last important point when choosing a laser cutter for home is the reliability and support of the supplier.

Reliability and support of the laser cutting machine supplier

Pay attention to how competent the supplier is in the matter. To do this, it would be better to communicate with several different suppliers and compare them.

Pay attention to the experience and production volumes of laser cutting machines from a specific supplier. Specify the geography and quantity of deliveries — a good product sooner or later inevitably reaches the international level.

Specify what specific responsibility the supplier bears under the warranty, whether he will be able to fulfill his obligations in your region and in what time.

Also, a good supplier helps with the commissioning of a laser cutter for home and training.

Advantages of laser cutting at home

If we compare laser cutting at home and laser cutting in the workshop, we can highlight a number of advantages of the first method:

- You can try to launch your business at no additional cost;

- There is no need to rent an additional room;

- Saving time on the way to the workshop;

- You can quickly carry out operational orders, as your laser cutting machine is always at hand;

Laser cutting machines cut the material at a speed of up to 150 mm/s and engrave at a speed of 500 mm/s, the service life of the laser emitter can reach 10,000 hours, which is about 5 years of continuous work for 8 hours a day with two days off a week.

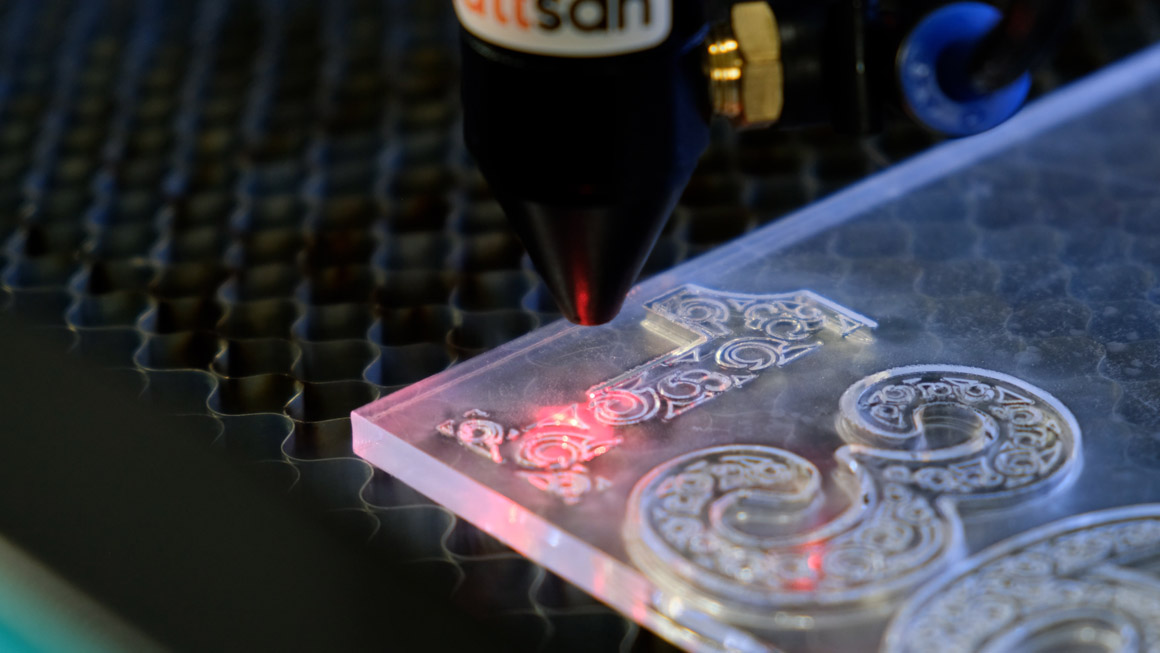

What materials are processed by a laser cutter for the home

The laser cutting machine works with the following types of materials:

- Wood materials (wood, plywood, MDF, cardboard, paper and other wood materials);

- Plastics and polymers (plexiglass, PET, polypropylene, foam, foam plastics, rubber and others);

- Composites, for example, paronite;

- Textiles, furs, leather and leatherette.

Also, the laser cutting machine for home can engrave most of the above materials, plus stone, ceramics, glass and mirror and some other materials.

What can be done with a laser cutting machine for home

Various things can be made on a laser cutting machine: from promotional products to children's educational toys. In fact, you have the above range of materials and two main methods of exposure: cutting and engraving. By combining different materials with these two methods of exposure, various interesting solutions can be achieved.

Products created with the help of laser cutting machines are used in the production of:

- Promotional products and POS materials;

- Interior and exterior decor;

- Furniture, lamps and decorative elements;

- Souvenir and award products;

- Prefabricated models, educational toys and puzzles;

- Car covers, patterns for sewing industries, cutting fur without damaging the pile.

Top 4 mistakes when working on a laser cutter at home

Buy a low-quality laser cutter for home

The main mistake is to purchase a low-quality laser cutter for home. To avoid this, you will have to better delve into the topic. Our article on the criteria for choosing a laser cutting machine will help you.

Not properly set up a laser cutter for home

In order for the laser cutter for home to work correctly, it is necessary to adjust it, adjust the current strength, tighten the belts to the proper degree, regularly maintain it to avoid breakdowns and be able to set the focal length.

Most of these tasks are performed by the supplier before sending the machine. However, some settings may go wrong during delivery. Virmer company not only does full pre-sale setup and preparation of its laser cutters for home, but also helps with commissioning and training.

Incorrectly prepare a file for laser cutting

To work correctly with a laser cutter at home, you need to master graphic programs for preparing files. To cut, you first need to create a vector image in any editor like Adobe Illustrator or CorelDRAW. Then open it in the machine program and start the machine to work.

Proper file preparation implies:

- correct export from third-party programs, it is better to use .ai, .dxf, .plt formats;

- absence of superimposed and double lines;

- scale 1:1, the size of the layout should fit into the working field of the machine;

- all objects must be without fill;

- when working with vector images, all elements must be rendered into curves;

- all curves must be closed;

- optimization of the cutting and engraving sequence.

Incorrect selection of cutting parameters

The key to a high-quality cut is properly selected indicators of speed and power. Otherwise, it is possible to under-cut or, on the contrary, burn the material, burning deposits during engraving, uneven trembling lines, burned at the corners when cutting.

If you need help in mastering the technology of file preparation and selection of laser cutting and engraving parameters, please contact Virmer: info@virmer.com; +31208082045.. Our engineers will conduct a basic or advanced training course on working with a laser cutter for home.

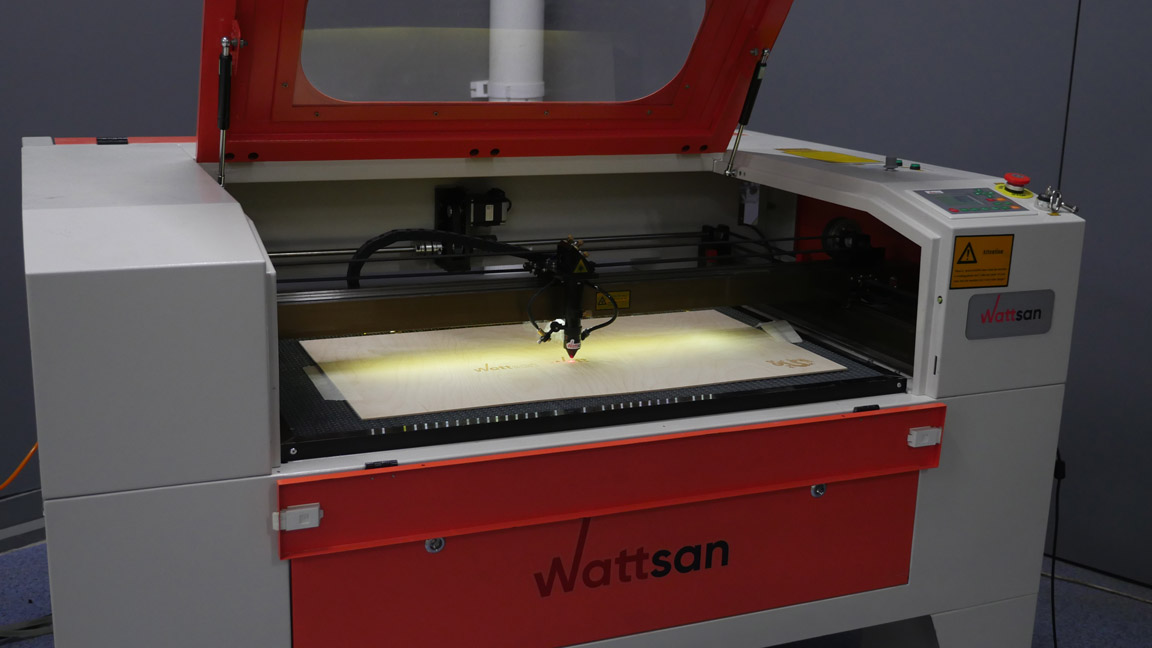

Wattsan Laser Cutters for Home

A distinctive feature of laser cutters for home on our website is the high quality of all models. For example, even desktop laser cutters for home Wattsan 0503 and Wattsan 6040 have a body thickness, motors and guides are the same as those of medium-format and large-format machines.

Of course, it will be necessary to change the laser emitter, since this part has a much shorter service life, but all the key components of the machine will still be in perfect working condition.

Desktop Laser Cutter for Home Wattsan 0503

Working field size: 500x300 mm;

Power: 60W;

Working life of the laser tube: 7000 hours;

Depth of lowering of the working table: 200 mm;

Cutting speed: up to 500 mm/s;

Engraving speed: up to 700 mm/s.

The price of the model starts from 3265 €, see the full specifications on the website or check with Virmer managers: info@virmer.com; +31208082045.

Wattsan 6040 model other things being equal, it has an increased size of the working field and the power of the laser tube is 80-90 W, compared to 60 W for Wattsan 0503. The price of Wattsan 6040 starts from 4319 €.

For more serious work, pay attention to the medium-format laser cutter for home Wattsan 6090 LT.

Medium Format laser Cutter for home Wattsan 6090 LT

Working field size: 600x900 mm;

Power: 80-90 W;

Working life of the laser tube: 10000 hours;

Depth of lowering of the working table: 160 mm;

Cutting speed: up to 500 mm/s;

Engraving speed: up to 700 mm/s.

This model is designed for round-the-clock operation, like all Wattsan laser cutters for home. The price of the model starts from 5213 €, the current price and detailed information about this model can be found on the website or check with Virmer managers: info@virmer.com; +31208082045.

If you are focused specifically on business and you have an idea how to adjust the flow of products to the sales markets, then to accelerate production it is better to choose a two-headed wide-format laser cutting machine Wattsan 1610 Duos ST.

Wattsan 1610 Duos ST Laser Cutting Machine

Of course, an appropriate room will be needed, but the performance of this model is doubled due to two laser heads that work simultaneously.

Working field size: 1600x1000mm;

Power: 100-120 W;

Working life of the laser tube: 10000 hours;

The depth of lowering of the working table: does not lower, the maximum thickness of the processed material is 40 mm;

Cutting speed: up to 500 mm/s;

Engraving speed: up to 600 mm/s.

The price of the model starts from 9151 €, for detailed information and the current price, see the website or check with Virmer managers: info@virmer.com; +31208082045.

Tips for laser cutting at home

- Think in advance how to organize the air exhaustion hood. If the hood will go outside, and you live in an apartment building, check with your neighbors whether this will interfere with them.

- Observe safety precautions. Work with the lid closed so as not to fall under the path of the laser beam, do not work with PVC and Teflon on a laser cutter for the house, as these materials emit dangerous gases when burning. Never leave the running machine unattended.

- Be sure to ground the machine. Proper grounding saves you from electrical injuries.

- Keep in mind that you will need a place to store the material and finished products.

- Use a voltage stabilizer. This will insure you against the failure of the electrics of the machine in the event of severe voltage drops or a sudden power outage.

- Price in the material for testing, selection of parameters and reject. If you have an order for a certain product, when buying the material, keep in mind that some of it will be spent to the selection of parameters. It is also impossible to insure against accidental reject, even large laser production plants put the percentage of reject products in the volume of material when purchasing.

- Don't skimp on the material. Cheap material will bring more problems than savings. For example, there will be a lot of undercuts on low-grade plywood due to knots and low-quality adhesive composition.

- Buy a good compressor. A standard compressor is included with any laser cutter for the home, but it does not have the ability to adjust the pressure. For some materials, it is necessary to apply more pressure, for example, 2 bar, and for some, on the contrary, less, about 0.5 bar. The compressor greatly affects the quality of cutting and engraving.

- Perform regular maintenance. To extend the service life of the laser cutter for home, wipe the laser tube from dust, clean the lamellas, the cellular table, guides and all optics. Check the frequency of maintenance with the supplier.

Conclusions on laser cutters for home

Laser cutting machine for home is a great idea for those who want to try themselves in laser cutting and engraving. A laser cutter for home can be both the beginning of an interesting hobby and the beginning of a profitable business.

The main thing is to choose a worthy supplier who will provide a high-quality laser cutting machine, warranty, service and training.

Sign up for an online demonstration of Wattsan laser cutting machines or come to our showroom in the Netherlands. Our managers are ready to answer all your questions: info@virmer.com; +31208082045.