Acrylic is very similar to glass, but it surpasses it in its quality characteristics. For example, the weight of acrylic is 2.5 times less, and the impact resistance is 5 times higher. Its light transmittance reaches 92%, so acrylic is used as a replacement for glass. At the same time, it is much more difficult to cut natural glass than to carry out laser cutting of acrylic.

Products made with the help of laser cutting of acrylic can be found everywhere — from shops to your own home. Thanks to the laser cutting of acrylic, we see price tags in stores, shop windows, advertising, packaging, elegant lamps with 3D effect, and sometimes we even take acrylic for ordinary glass.

In this article you will read about how CNC acrylic laser machines work, why and how acrylic laser cutting is generally possible, what types of acrylics there are and which type is better to choose.

How does laser cutting of acrylic work?

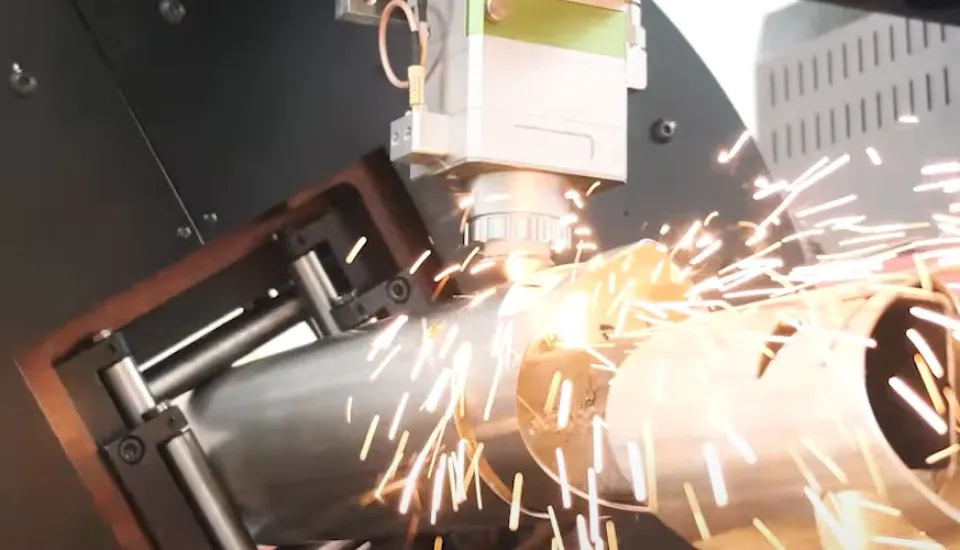

Laser cutting of acrylic occurs due to the impact of a focused laser beam on the surface of the material. For this purpose, special CO2 laser CNC machines for acrylic are used.

Why is the acrylic laser machine called CO2

At the heart of the acrylic laser cutting machine is a carbon dioxide emitter — a multilayer glass flask with a mixture of gases, the main of which is carbon dioxide. Gases in this case are the active medium, which, under the influence of electricity, forms a laser beam for the implementation of laser cutting of acrylic.

What is a CNC

CNC means Numerical Program Control, in this case it is a way of coordinating all the moving parts of the laser machine on acrylic and activating laser radiation at the right moment at the right percentage of power to carry out laser cutting of acrylic.

To understand how laser cutting of acrylic is possible and to illustrate the principle of operation of a laser machine on acrylic, you need to imagine its design.

The principle of operation of the acrylic laser cutting machine

To carry out laser cutting of acrylic, a sheet of material is laid on the working field. The emitter of an acrylic laser machine is usually located in the back of the housing under a closed lid, separate from all other units of the acrylic laser machine.

In order to direct the generated laser beam to the desired point of the working field and carry out laser cutting of acrylic, a system of movable mirrors is used. The first mirror is fixed directly at the laser emitter, it receives the outgoing laser beam and directs it to the second mirror, which is fixed on the portal and moves with it along the Y axis.

The beam is reflected from the second mirror and passes to the third, mounted on a laser head that moves along the portal along the X-axis. The last third mirror directs the laser beam strictly perpendicular to the working field through the focusing lens to the material.

How does laser cutting of acrylic work?

The focused beam of the acrylic laser machine has a diameter of 0.03 mm and, due to this, a high power density. This means that on a small area of the material during laser cutting of acrylic, there is a high intensity of exposure.

An acrylic laser cutting machine supplies an air stream to the cutting zone, which helps the laser beam burn through the material, and also blows out combustion products (carbon deposits and acrylic vapors) from the acrylic laser cutting zone.

Advantages of acrylic laser cutting

Due to its properties, laser cutting of acrylic has a number of advantages over other methods:

- Cutting quality. After laser cutting of acrylic, the edge of the material turns out to be transparent, clean and smooth;

- High cutting speed. Compared with traditional methods, laser cutting of acrylic is several times faster;

- The accuracy of laser cutting of acrylic is 0.03 mm. This allows you to perform work with high tolerance requirements, reduces material overruns during laser cutting of acrylic, since a thin laser beam does not affect the material adjacent to the cutting line.;

- The CNC allows you to keep tolerances, perform laser cutting of acrylic along complex trajectories, reduces the reject rate to zero and guarantees the repeatability of the cut products;

- Non-contact exposure. During laser cutting of acrylic, the material is not damaged, since it does not need to be fixed and there is no mechanical impact of the cutting tool;

- Cutting tool. The laser is not blunt and the acrylic does not stick to it, unlike mechanical cutting methods;

- Service life. The life of the laser tube depends on the manufacturer and can reach 10,000 hours. This is 4.7 years of work, if you count the standard 8-hour shift 5 days a week;

- No chips and dust. The laser gently and cleanly melts acrylic, without creating byproducts of laser cutting of acrylic;

- Low noise level. The laser has no physical contact with the material, so the laser cutting of acrylic is quiet;

- Easy to master. You can learn the basic principles of working on an acrylic laser machine in a few hours;

- Multipurposeness. The acrylic laser machine also works with other materials: any type of wood materials, various plastics, textiles and leather. The acrylic laser machine can not only cut, but also engrave;

What can be done with the help of an acrylic laser cutting machine

Today it is difficult to imagine a person who would not meet with products made with the help of laser cutting of acrylic on a daily basis. Judge for yourself, they are made of acrylic:

- Interior and exterior decor;

- Souvenir products;

- Elements of outdoor advertising;

- POS products;

- Elements of architecture;

- Building elements;

- Lighting equipment;

- Cases, panels, dials and other elements of devices;

- Storage tanks;

- Aquariums and terrariums;

- Other products.

What kind of acrylic is there and what are the differences between different types of acrylic?

Types of Acrylics

In color, acrylic is not only transparent, with the use of special dyes in production, a colored, mirror or translucent material is also obtained.

According to the production method, there are two types of acrylic: extrusion and injection molding. Each type has its own properties.

Extruded acrylic for laser cutting

Extrusion acrylic is obtained when an acrylic mass is fed through an extruder under pressure. The slot of the extruder, and hence the thickness of the material, can be from 1 to 24 mm.

Advantages:

- Small divergence in sheet thickness (up to 5%);

- Any length up to 4 meters;

- Requires less power for laser cutting acrylic;

- The price is lower than that of molded acrylic;

- Requires less effort for vacuum forming, makes products of complex shapes better.

Disadvantages:

- Thickness from 1 to 24 mm;

- Residual stress and weak molecular bonds;

- Fragility of the material;

- The engraving is obtained with a gray tint;

- Not suitable for vacuum reshaping.

Molded acrylic for laser cutting

Injection-molded acrylic is obtained when a liquid acrylic mass is poured between two sheets of glass under pressure.

Advantages:

- Almost any thickness;

- Strong molecular bonds, no residual stress;

- Higher impact resistance compared to extrusion acrylic;

- Surpasses extrusion acrylic in light transmittance;

- The engraving turns out to be perfectly white;

- Allows vacuum reshaping of the product.

Disadvantages:

- The dimensions are strictly limited in length and width;

- The price is higher than that of extrusion acrylic;

- The divergence in sheet thickness is up to 30%, which complicates the production of prefabricated elements;

- Vacuum forming requires more effort compared to extrusion acrylic.

For laser cutting of acrylic, injection-molded acrylic is more advantageous, since the extrusion one often cracks due to residual stress.

To what thickness is laser cutting of acrylic possible

One of the most frequent questions when buying an acrylic laser machine is to what maximum thickness is laser cutting of acrylic possible?

Laser machines on acrylic confidently cut material with a thickness of 20 mm. At the same time, you can make laser cutting of acrylic with a thickness of 25 mm, but in this case you will have to put up with a low speed of work and, most importantly, a clear taper of the edge will appear.

Acrylic Engraving

We should also focus on engraving, since this feature is an undeniable advantage for an acrylic laser machine compared to other methods of cutting acrylic.

Laser engraving of acrylic allows you to significantly expand the production capabilities. With the help of an acrylic laser machine, you can cut out products and immediately put the necessary information on them in the form of inscriptions or images.

Wattsan Acrylic Laser Machines

For high-quality laser cutting of acrylic and long trouble-free service in Wattsan acrylic laser machines, the following advantages are realized:

- Machine bed with reinforcement frame. It affects the stability of the laser machine on acrylic, levels vibrations, guarantees the preservation of the accuracy of the laser cutting of acrylic throughout its service life;

- Housing thickness. The thickness of the housing of Wattsan acrylic laser machines is 2.9 mm;

- Reliable portal. It is important to preserve the service life without errors. The aluminum portal of Wattsan acrylic laser machines has a thickness of 7 mm at the corners;

- Three-phase stepper motors. They have a greater step discreteness compared to two-phase ones, as well as greater accuracy and faster acceleration and deceleration;

- The correct location of the motors. The Y-axis motor should be positioned in the middle of the shaft to avoid distortion of the motion geometry during operation;

- Gearboxes of motors. Increase the resolution of engraving, extend the service life of engines. The ratio of gearboxes on acrylic Wattsan laser machines is 1 to 6;

- Belts. Neoprene belts reinforced with fiberglass cord 3M are installed on Wattsan acrylic laser machines;

- End sensors. Inductive end sensors are more reliable than mechanical ones, as they are not affected by dust, dirt, resins and other byproducts of laser cutting of acrylic;

- A system of optics and mirrors. Lenses are coated with polycrystalline zinc selenide, molybdenum mirrors, high-quality laser head mount, convenient focus adjustment and alignment system;

- Laser tube mounts. They have adjustment wheels for adjusting the position of the laser tube;

- Nozzle diameter. The nozzle is optimized for a specific task: for laser cutting of acrylic, a truncated nozzle is installed, which improves cutability, and for engraving, a nozzle with an expanded diameter, which reduces burn deposits at the edges of the engraving;

- Blowing hoses. On Wattsan acrylic laser machines, reinforced polyurethane blowing hoses can withstand a pressure of up to 8 bar;

- Anodized lamellas. The lamellas are anodized, which eliminates burns and back shoots on the reverse side of the material;

- Waste collection chamber. Helps to collect leftover material and finished products. Being a part of the housing, it gives it additional reliability, improves the operation of the hood, protects the lifting chain of the table from jamming;

- Table lifting mechanism. The chain lifting mechanism of the table can withstand loads up to 80 kg;

- Safety. The electrics of the acrylic laser machine and the water hoses are separated into different parts of the housing;

- Potentiometer. Enables fine power adjustment.

All of the above advantages are realized in most models of Wattsan acrylic laser machines. Models marked ST have a static table, and LT has a lifting table. The main parameters that need to be determined are the size of the working field and the power of the laser tube.

The best solution for large-format acrylic laser cutting without pre-cutting is the Wattsan 2030 FlatBed acrylic laser machine.

Wide-format laser machine for acrylic Wattsan 2030 Flat Bed

The power of its laser tube 100-130 W guarantees high speed operation.

The size of the working field is 2000x3000 mm and even with such dimensions Wattsan 2030 Flat Bed retains the accuracy of work within 0.03 mm.

For more information about the Wattsan 2030 Flat Bed acrylic laser machine, see our website, the approximate price of the machine is 16 747 €, check the current price with the managers of the Virmer company: +31208082045, info@virmer.com.

If you need a medium-format acrylic laser machine and at the same time you are aiming for high performance, pay attention to two-headed machines such as Wattsan 1610 Duos ST.

Medium-format laser machine for acrylic Wattsan 1610 Duos ST

Two laser heads synchronously perform the same work. Accordingly, two laser tubes with a power of 100-130 watts are installed in this acrylic laser machine.

The size of the working field is 1600x1000 mm. A through hole at the table level allows you to stretch the material of any length, if it fits the width.

Read more on our website, the approximate price of the machine is 9 151 €, check the current price with the managers of the Virmer company: +31208082045, info@virmer.com.

If you are looking for a universal acrylic laser machine that can work with a rotary device and materials up to 160 mm thick, then Wattsan 6090 LT will suit you.

Universal laser machine for acrylic Wattsan 6090 LT

The power of the laser tube is 90-100 watts. The size of the working field is 600x900 mm.

The lifting table is lowered by 160 mm, allows you to connect a rotary device and work with thick materials.

For more information, see the link, the approximate price of the machine is 5 213 €, check the current price with the managers of the Virmer company: +31208082045, info@virmer.com.

This is far not a complete list of Wattsan acrylic laser machines, so if you need help in selecting equipment and detailed advice, please contact Virmer: +31208082045, info@virmer.com.

Advantages of working with Virmer:

- Detailed consultation from specialists in laser machines for acrylic;

- Showroom in the Netherlands, online demonstrations at any time from anywhere in the world;

- Delivery and warranty for equipment;

- Assistance in commissioning and embedding an acrylic laser machine in the production process;

- Basic training from Virmer engineers;

- Warranty and post-warranty service.

- Lifelong information support.