The laser cutting machine is one of the most profitable tools for high-quality and fast cutting of acrylic. Laser machines are capable of cutting acrylic up to 25 mm thick, while the face of the cut material remains transparent and clean.

In this article we will tell you how to choose the right acrylic for laser cutting, according to what parameters it is worth choosing a laser machine for cutting acrylic and we will make up our TOP laser machines for acrylic.

TABLE OF CONTENT

- What is acrylic and what are the types of acrylic

- Areas where laser cutting of acrylic is used

- Advantages of acrylic laser cutting

- Which acrylic to choose for laser cutting

- The principle of operation of the acrylic laser cutting machine

- How to choose an acrylic laser cutting machine

- Top 3 laser cutting machines for acrylic

- Conclusion

- FAQ

What is acrylic and what are the types of acrylic

Acrylic (other names: polymethylmethacrylate, plexiglass) is a thermoplastic polymer similar to glass, but more durable and lightweight: the weight of acrylic is 2.5 times less, and the impact resistance is 3-5 times higher.

The light transmittance of acrylic reaches 92%, so this material is often used instead of glass. At the same time, cutting acrylic with a laser machine is much easier than cutting glass in traditional ways.

Acrylic can be not only transparent, but also translucent, colored or mirrored.

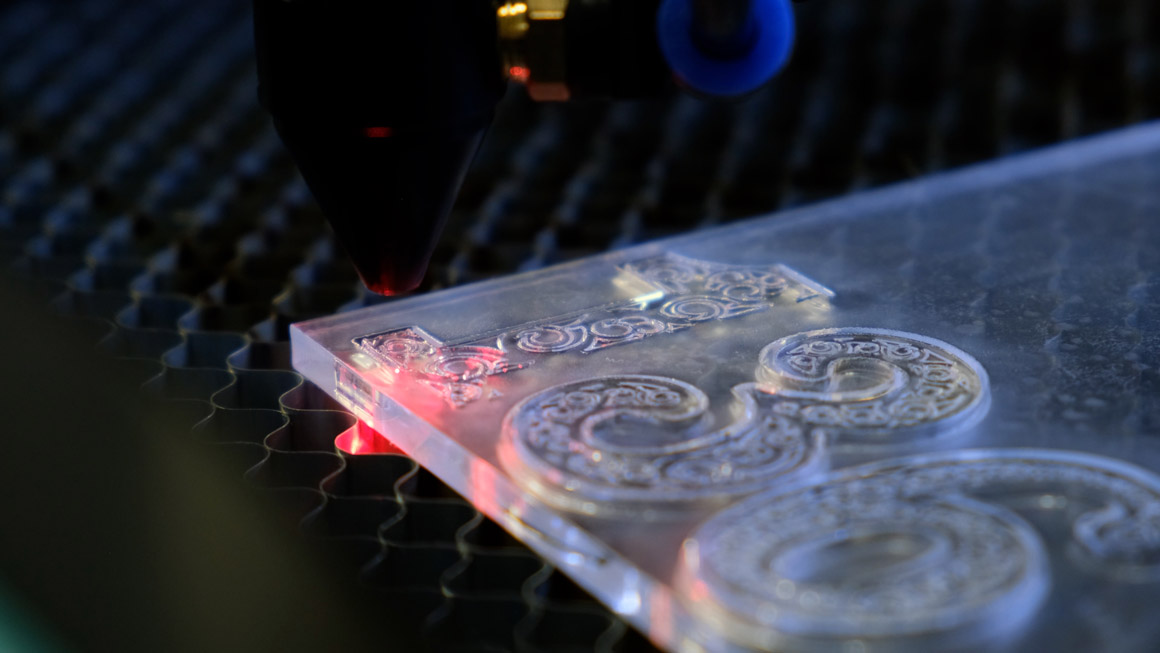

After laser cutting, it is very easy to give the necessary shape to the acrylic with the help of special bending machines. Also, on a laser cutting machine for acrylic, you can not only cut the material, but also engrave it.

Due to the simplicity of processing and wide application possibilities, acrylic is used in many areas.

Areas where laser cutting of acrylic is used:

- Outdoor advertising: light displays, boxes for neon signs and advertising, signs and pointers, three-dimensional letters;

- POS-products: badges, plates, numbers, price tags, wobblers, dispensers, stands for printing, money holders, exhibition stands and showcases;

- Construction and architecture: greenhouses, partitions, domes, transparent floors, doors and fences, suspended ceilings with internal lighting,

- Interior and exterior decoration: designer tables and chairs, coffee tables, wall decorative elements, volumetric molded products, lamps and sconces, illuminated decor;

- Lighting equipment: lamps with engraving and LED-illumination, lampshades and diffusers;

- Instrumentation: cases and equipment elements, viewing windows, dials;

- Souvenir products: key chains, magnets, jewelry boxes, award products;

- Other products: storage boxes, containers for bulk products, aquariums and terrariums, rulers, business cards, etc.

Advantages of acrylic laser cutting:

- High quality at high cutting speed. Laser cutting of acrylic is several times faster than mechanical;

- The face of the product at the cutting point turns out to be perfectly smooth and transparent, so no post-processing is needed.;

- Non-contact processing reduces the likelihood of damage to the material, since there is no direct impact of the cutting tool on the material and it does not need to be fastened;

- The positioning accuracy of the acrylic laser machine reaches 0.03 mm, which allows you to perform precision work with many small parts;

- The acrylic laser machine works on the basis of CNC (numerical control) – this guarantees repeatability and almost completely eliminates defects from the production process;

- The basic principles of working on an acrylic laser cutting machine can be mastered in one working day;

- The acrylic laser machine can not only cut, but also engrave;

- The CNC laser machine works not only with acrylic, but also with other materials: wood, plywood, MDF, veneer, cardboard, almost all types of polymers and plastics, leather, leatherette, textiles, engraving on stones and ceramics is possible.

Acrylic is a rather expensive material, so in order not to spoil it during laser cutting, you need to understand how to work with it and how to choose it.

Which acrylic to choose for laser cutting

Acrylic is produced by two methods: by molding and by extrusion. Each method gives the material certain properties.

Extruded acrylic for laser cutting

To obtain extruded acrylic, the acrylic mass is supplied under pressure from the slot of the extruder. The thickness of the material in this case depends on the extruder and ranges from 1 to 24 mm. The divergence in the thickness of the sheet in the batch has a tolerance of up to 5%. Thanks to this method of production, sheets of extruded acrylic can have a length of up to 4 meters, in contrast to the much more limited length of molded acrylic.

But the main difference is the molecular bonds: with the extrusion method of production, they are less durable. The material has a residual stress, so after cutting, a sheet of such acrylic may crack.

Extruded acrylic is not suitable for laser cutting, because the residual stress of the material leads to cracks.

Laser engraving of extruded acrylic is obtained with a gray tint, which also does not always meet the quality requirements.

One of the advantages is that cutting extruded acrylic requires relatively less laser power than for molding. In addition, extruded acrylic is cheaper. It can also be noted that extruded acrylic has a lower viscosity at high temperatures, that is, it is more stretchable. Therefore, vacuum forming requires less effort and reproduces complex shapes more accurately.

Extruded acrylic is more brittle than molded acrylic and has less chemical resistance, but it adheres better.

Molded acrylic for laser cutting

To make a molded acrylic, a liquid methyl methacrylate monomer is poured under pressure between two sheets of glass. After pouring, the material is polymerized and cut to standard sizes. For this reason, the dimensions of the molded acrylic sheet have strict restrictions on length and width. But the thickness of the material can be almost any, unlike extruded acrylic.

The advantage of molded acrylic is stronger molecular bonds and the absence of residual stress. Therefore, the probability that the acrylic will crack during or after laser cutting is reduced to almost zero. Molded acrylic is more impact-resistant and, of course, more expensive than the extruded one.

The permissible divergence of molded acrylic in thickness reaches 30%. Consider this parameter if it is important for your type of product, for example, for prefabricated elements.

Molded acrylic is somewhat superior to extruded in its optical properties. It is also better suited for laser engraving, since as a result you can get a clear white image or inscription.

For forming the molded acrylic, more effort is required, but less shrinkage of the material is obtained, and the product comes out stronger and more reliable than from extruded acrylic. In addition, molded acrylic products can be reformed if necessary.

CONCLUSION: for laser cutting and engraving of acrylic, the material made by molding is better suited, despite the fact that it is more expensive and has a large divergence in thickness.

The principle of operation of the acrylic laser cutting machine

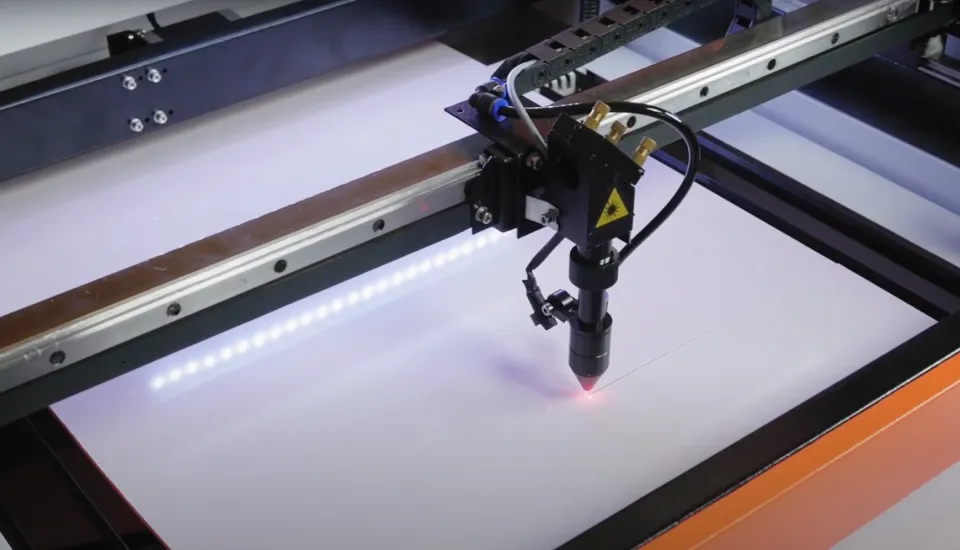

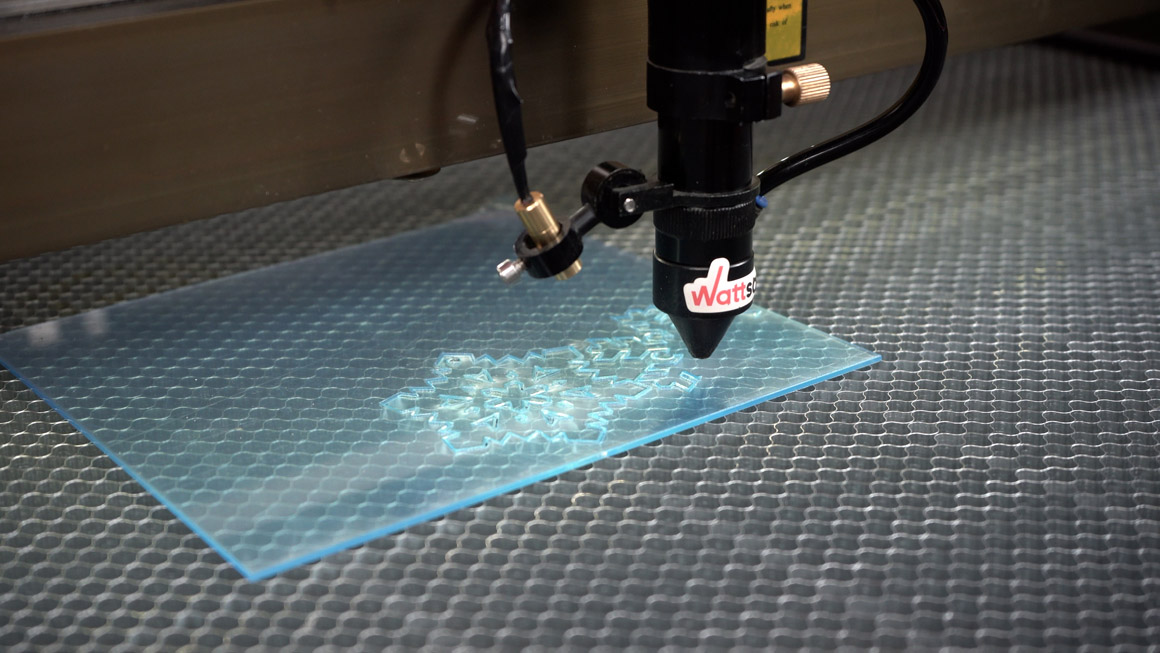

Laser machines with a CO2 emitter are used for laser cutting of acrylic. This type of emitter is called a “laser tube”, it is a flask filled with a mixture of gases in the medium of which laser radiation is generated using electricity and then directed through a system of reflecting mirrors and a focusing lens to the material.

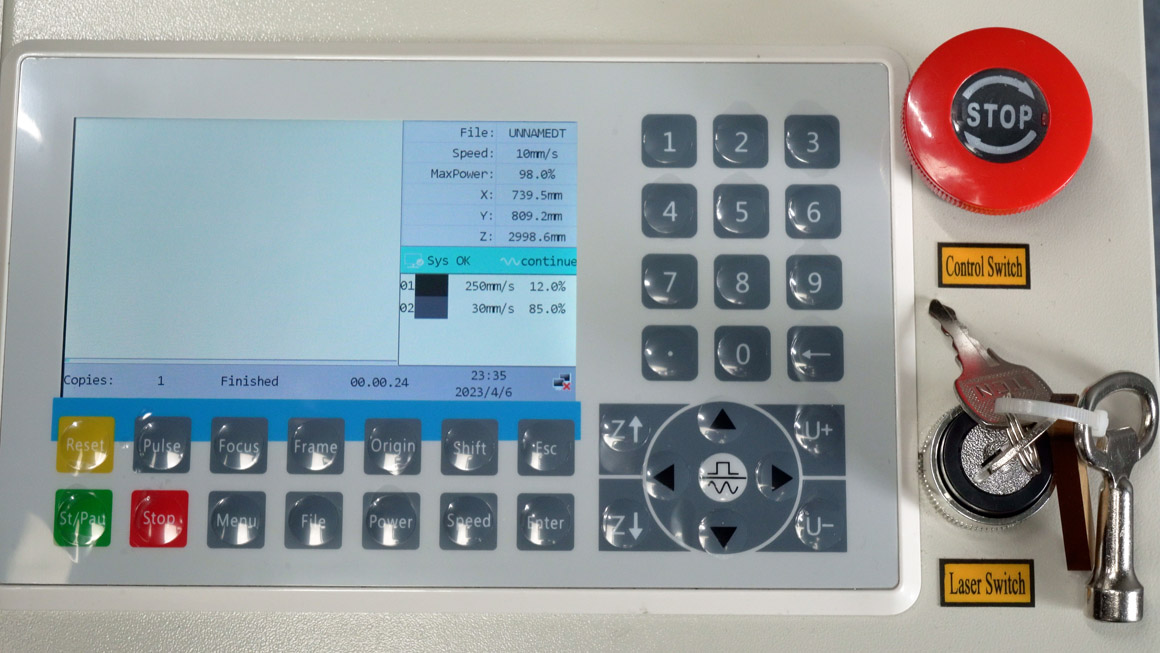

Mirrors are located on the moving parts of the machine, so the laser beam can be directed to any point on the surface of the working field of the laser machine. Each point has its own coordinates and the control system of the machine directs the laser beam to the desired coordinate and activates the laser radiation at the right moment. This is called “Numerical Control" or CNC.

How to choose an acrylic laser cutting machine

The laser acrylic cutting machine has several basic parameters that are important to consider when choosing, these are:

- The size of the working field.

- Laser tube power,

- Frame and body of the acrylic laser machine,

- Portal,

- Lamellas,

- Other components,

- Software,

- Reliability of the supplier.

Let's analyze each item in more detail.

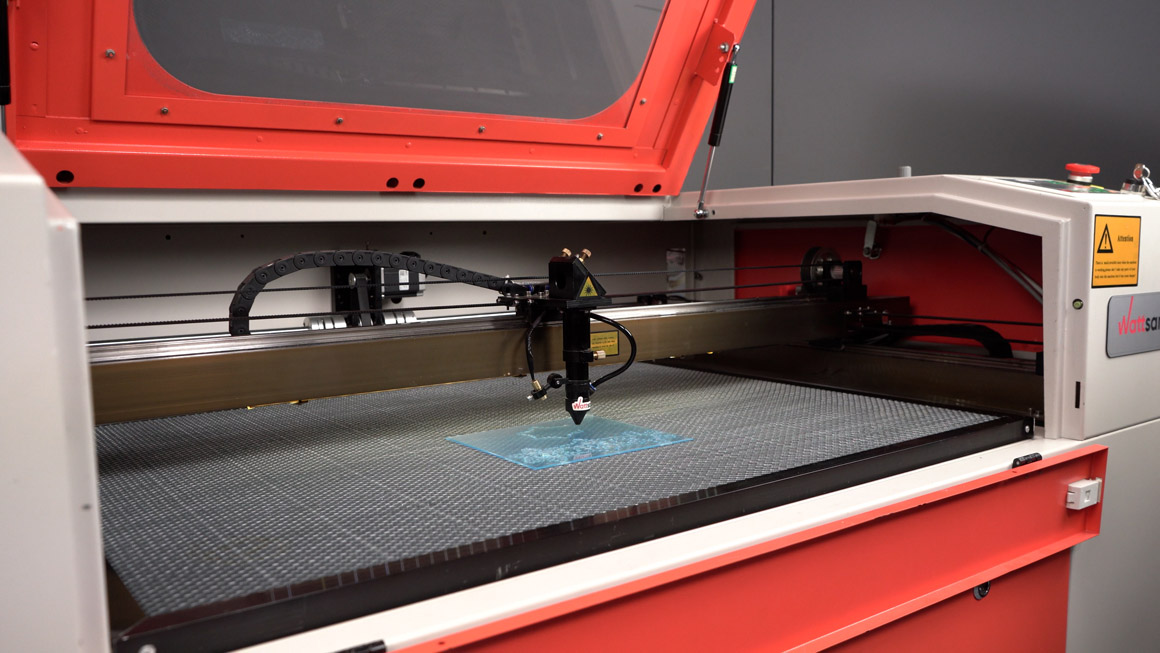

The size of the working field of the laser machine on acrylic

The size of the working field of the machine influences not only the area occupied by it, but also on the convenience and speed of work.

The actual dimensions of the laser machine are larger than the size of its working field. Keep this in mind when planning the arrangement of a production facility or workshop.

All types of sheet materials have their standard dimensions in length and width. These sizes determine whether you need the preliminary material cutting. If this is the case, then it is necessary to provide additional workspace for cutting the material and purchase a tool for these tasks.

Thoughtful machines, for example, such as Wattsan, have a through hole at the level of the working table. This allows you to pull the material to any length and work with it without preliminary cutting or cut the material on the machine, if the material fits the width.

On large-format acrylic laser machines, you can make large-sized products. We have interviewed our customers and more than 82% of them recommend purchasing an acrylic laser cutting machine with a margin for the size of the working field.

When manufacturing medium-format and small-format products on a large-format acrylic laser cutting machine, you will save time on changing the material.

The power of the laser tube of the acrylic laser cutting machine

The higher the power of the laser tube, the faster the acrylic laser machine will cut the material. The material with a thickness of up to 10 mm can also be cut with a laser tube with a power of 50 watts, but for efficient operation we recommend using at least 80 watts.

The laser tube can be replaced with a more powerful one. If you plan to do this, check with the supplier whether it will fit into the machine body. Not all machines have the ability to upgrade the laser tube.

Well-thought-out machines, such as Wattsan, have side openings in the housing that allow you to install more powerful laser tubes and close them with a protective casing.

The largest thickness of acrylic that can be cut with a laser machine is 25 mm. With a larger thickness, it is difficult to achieve a high-quality cutting result.

Are there any further questions about choosing the power of the laser tube? Ask the managers of Virmer: +31208082045, е-mail: info@virmer.com.

Frame and body of the acrylic laser machine

One of the most important enemies when laser cutting acrylic is the vibration of the machine. They can spoil expensive material: small teeth will appear on its end after cutting, like on the edge of a 50 cent coin. This is called a “coin cut” and products with such a defect are considered defective.

One of the most important elements of the machine that helps to neutralize vibrations is its body. The thickness of the machine body with a working field size of 600x900 mm or more should be at least 2 mm. For example, Wattsan machines have 2.9 mm.

Machine tool manufacturers often neglect the internal reinforcement frame around the perimeter of the body, as this complicates and makes the production process more expensive. Be sure to pay attention to this when communicating with a potential supplier.

Portal of the acrylic laser cutting machine

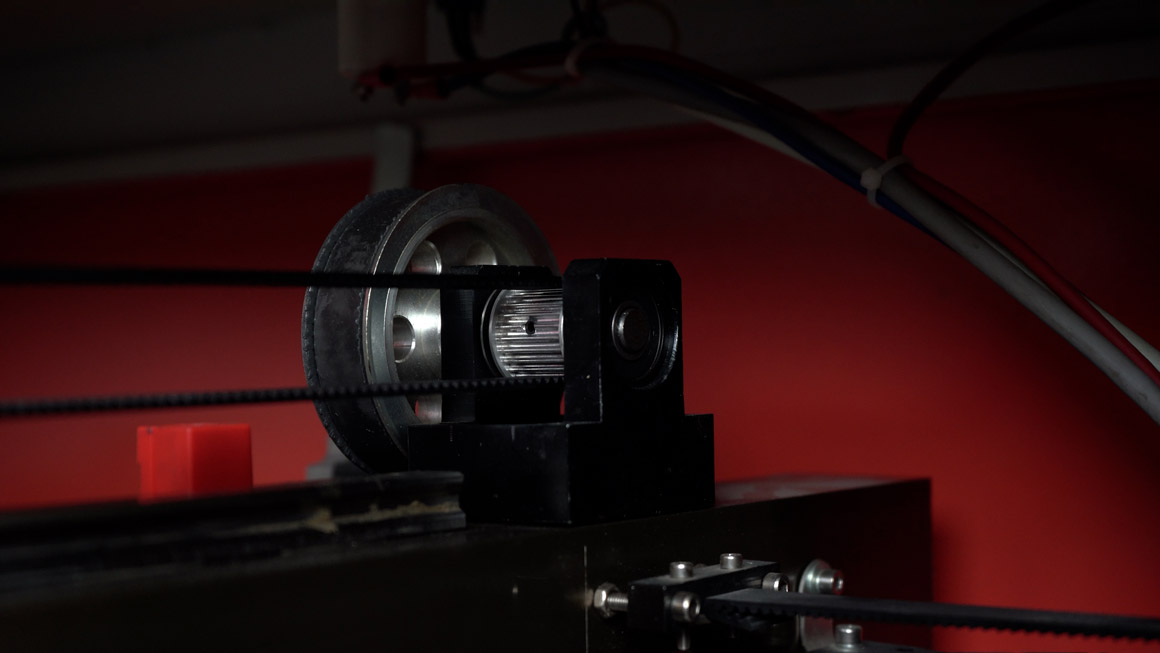

The portal is one of the main movable elements of the laser machine, it moves along the Y axis, and the working head moves along the X axis along the portal itself.

A high-quality portal is the key to long-term accuracy in the operation of such equipment. When choosing, pay special attention to its design and thickness – if the portal is made of steel or aluminum bar, it will quickly lose its geometry during operation.

A high-quality portal should be made of aluminum profile with a wall thickness of 3 mm.

Lamellas

Lamellas for a laser machine are usually made of aluminum. However, aluminum has a high reflection coefficient. Because of this, so-called “back-shoots” appear on the reverse side of the material after laser cutting - traces of reflected flashes of laser radiation that occur when the laser beam passes directly over the lamella.

Back-shoots on acrylic is considered a manufacturing defect. In some cases, they can be disposed of by polishing, but this increases the cost of the production process.

To solve this problem, the lamellas are anodized. This allows you to almost completely get rid of back-shoots and get a high-quality cutting result. The problem is that anodizing also adds a rather significant amount to the cost of the machine, mainly due to environmental requirements for production. Therefore, many manufacturers neglect the anodizing of lamellas.

Other components of the acrylic laser cutting machine

In addition to all the above points, when choosing a laser machine for cutting acrylic, pay attention to the following components:

- Motors. Three-phase motors give higher accuracy than two-phase motors. Give preference to motors with gearboxes, because they break up the pitch of the engine and remove the load from it when working;

- Optical system. Mirrors should have convenient bolts for alignment (adjusting) the optical path;

- The mounting of the laser tube should be able to adjust the position of the emitter;

- Belts. A reinforced belt with a tooth pitch of 3M is the optimal solution for laser machine loads, thinner belts quickly become unusable.

- Opening elements of the body. As a rule, the machine has opening doors on all sides – some for ease of adjustment, some for access to certain parts of the machine. Check whether it is convenient for you to open all the doors and whether you have access to all the elements.

- Water flow sensor. The laser tube is continuously cooled during machine operation. If for any reason the water flow stops, such a sensor will stop working and keep your emitter from failing due to overheating.

To learn more about choosing a laser machine, read our article: "How to select a laser cutting machine?" or contact Virmer managers: +31208082045, е-mail: info@virmer.com.

Software of the acrylic laser cutting machine

As a rule, software is supplied with the machine, with which you can download vector or bitmap images for work. These images can be prepared both in the operating program itself and with the help of third-party software, for example, such as CorelDRAW or Adobe Illustrator.

To master the basics of working on a laser machine, you only need a few hours.

When buying equipment from Virmer, you get basic training along with commissioning. If you need advanced training, inform the Virmer manager about it: +31208082045, е-mail: info@virmer.com.

Reliability of the supplier

Since an acrylic laser cutting machine is quite expensive equipment, it is important to reduce the risks when buying and have guarantees after. The following few recommendations for choosing an equipment supplier are intended for this purpose. Always pay attention to the following nuances:

- Competence. The extent to which the supplier understands the equipment influences on whether he will be able to choose the right equipment for you. For example, at Virmer, we understand not only the machines themselves, but also all the production processes associated with them. Therefore, we can tell you in detail how to work with a particular material, choose a suitable machine for your tasks, integrate equipment into the production process and help if you have practical questions about working with laser machines.

- Demonstration of equipment. A professional supplier will always invite you to their showroom or conduct a demonstration online. At Virmer, you can ask the manager to show you how to work with a certain material and ask all the questions you are interested in. Visit our demo hall in the Netherlands to see the equipment live and chat with our specialists.

- Warehouse availability indicates the possibility to buy a machine or components without waiting for a long delivery. In Virmer, we have world-famous manufacturers in stock: Wattsan, Hiwin, S&A, Reci, Ruida, ets.

- Delivery. Ask about the possibility and timing of delivery to your region. Virmer delivers machine tools and components anywhere in Europe. We take full responsibility for the delivery and do not shift it to the transport company.

- Pre-sale service. Our task as a supplier is to minimize the complexity for the buyer after the purchase of the machine, so before shipping we set up and adjust the machine so that our customers do not have to do it.

- Training. If you have no experience working on a CNC laser machine, it will be difficult to figure everything out on your own. Virmer is ready to send its engineers to you for staff training.

- Information support after purchase. After purchasing the machine, our cooperation with you does not end. You can always ask any questions to the manager of the Virmer company about the machines or about the process of working on it, if you have any difficulties.

- Warranty and post-warranty service. Virmer gives a 24-month warranty with the possibility of extension up to 60 months. If necessary, we help to modernize the machine for new tasks.

Now we will present to your attention the TOP acrylic cutting machines according to our company's version.

Top laser machines for cutting acrylic

As we wrote above, the best solution for cutting acrylic will be a large-format laser machine, so the first in our top is a machine with a working field size of 2000x3000 mm.

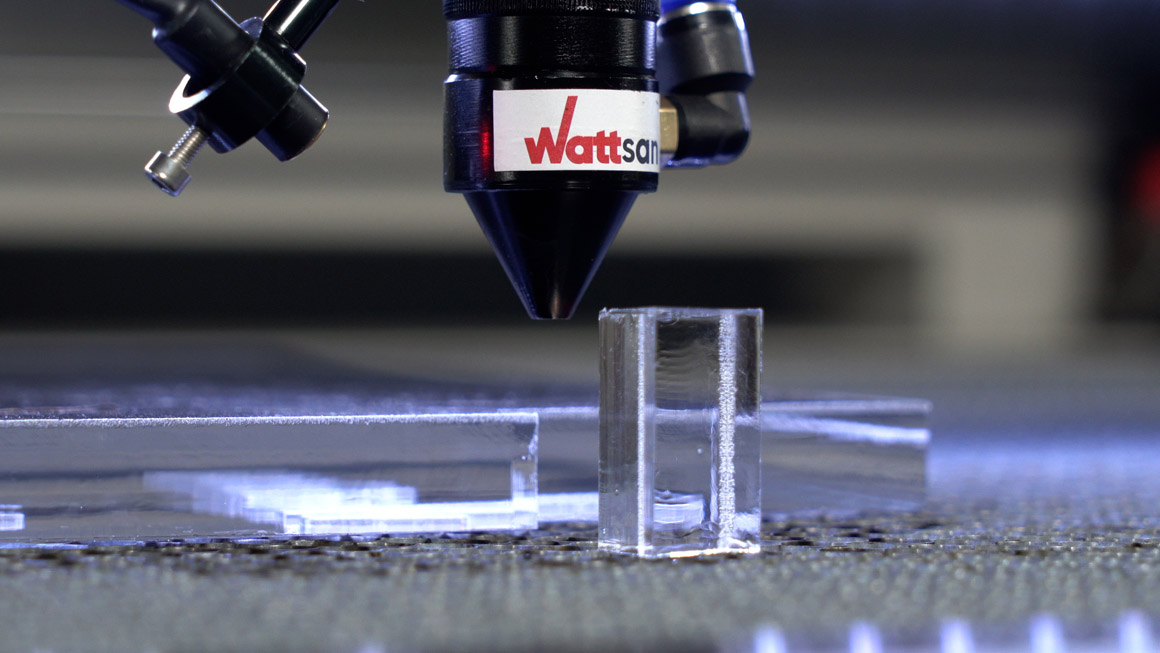

Wide-format laser cutting machine for acrylic Wattsan 2030 Flat Bed

With this machine, you will achieve truly amazing speeds when cutting acrylic and other plastics, since the power of its laser tube is 100-130 watts.

The size of the working field 2000x3000 mm allows you to cut most types of acrylic without preliminary cutting.

Despite such dimensions, the machine retains a positioning accuracy of 0.03 mm.

You can find detailed information about this model on our website: Wattsan 2030 Flat Bed, the machine price is about 16 747 €, check the actual price with the managers of the Virmer company: +31208082045, е-mail: info@virmer.com.

If you want to speed up the cutting process, pay attention to laser machines with two working heads, for example — Wattsan 1610 Duos ST.

Wide-format laser cutting machine for acrylic Wattsan 1610 Duos ST

This model has a slightly smaller desktop size — 1600x1000mm, but it is equipped with a through hole at the level of the working field, which allows you to use material of any length if its width does not exceed 1600 mm.

The main distinguishing feature of this laser machine is two laser heads that work simultaneously and perform the same task in parallel. Thanks to this feature, you speed up the production process twice.

Wattsan 1610 Duos ST is equipped with two working tubes with a power of 100-130 watts each.

For more information about this model, see the link: Wattsan 1610 Duos ST, the machine price is about 9 151 €, check the actual price with the managers of the Virmer company: +31208082045, е-mail: info@virmer.com.

If you need a universal laser machine that will not only cut acrylic, but will also be able to work with thick materials and with a rotary device, then Wattsan 6090 LT will suit you.

Medium-format laser cutting machine for acrylic Wattsan 6090 LT

The main difference of this machine compared to those presented above is the lifting table, which can be lowered by 160 mm. We can say that this model is suitable for those who assume a more universal use of a laser machine, including engraving on cylindrical surfaces using a rotary device and working with materials of large thickness, for example, PU foam or foam plastic.

All CO2 laser machines are capable of cutting not only acrylic, but also other materials: plywood, wood, MDF, veneer, PET, polystyrene, foam rubber and other polymers, textiles, leather and leatherette, fur, cardboard and paper, etc.

The size of the working field Wattsan 6090 LT: 600x900 mm, so you will need to order sheets of acrylic for this size or have a specially equipped place for cutting the material.

The power of the laser tube is 90-100 watts. For more information about this model, see the link: Wattsan 6090 LT, the machine price is about 5 213 €, check the actual price with the managers of the Virmer company: +31208082045, е-mail: info@virmer.com.

Please note that other Wattsan machines can also be equipped with a lifting table. Such models have the signature “LT”, and models with a static table are designated as “ST”.

The choice of equipment for cutting acrylic with a laser is not limited to this list of machines and largely depends on your tasks. We recommend contacting the manager of the Virmer company for detailed advice: +31208082045, е-mail: info@virmer.com.

Conclusion

It is important not only to choose the right laser machine, but also to know how to use it, since each material has its own processing characteristics. If you need help in choosing equipment or training on how to work with it, contact Virmer.

FAQ

What type of acrylic is safe for laser cutting?

When using an exhaust hood, working with any acrylic on a laser machine is absolutely safe, there is no need to use additional respiratory protection. It is forbidden to cut PVC and vinyl with a laser due to the release of toxic gases during cutting.

Is it possible to cut acrylic with a laser?

CO2 laser machines are one of the highest quality, fastest and most convenient ways to cut acrylic. The laser beam cuts the material so that its face remains smooth and transparent, which is necessary for the production of most types of plexiglass products.

Which plastic is best suited for laser cutting?

One of the most common plastics for cutting with a CO2 laser machine is acrylic. This material can be both transparent and have different colors and shades. PET, polystyrene, foam rubber and other polymers can also be cut on a laser machine.