Advantages of cutting metal with a laser

Metal laser cutters are most efficient when cutting metal up to 40 mm thick. Laser metal cutting has a number of advantages in comparison with other metal cutting methods:

- High precision metal cutting. The metal laser cutter cuts metals accurately and precisely, obtaining contours of any complexity, as the focused laser beam is thinner than a hair. Metal laser cutting machines have a positioning accuracy of 0.02 mm.

- No material deformation. The properties of the laser beam allow thin metals to be cut without overheating or deformation.

- Operation speed. Some models have idle speed up to 120 m/min and working speed up to 60 m/min.

- High cutting quality. The material does not require post-processing as there are no dross, deposits, burrs or tapered edges when the metal is cut by laser.

- Laser metal cutting efficiency >40%. This incomparably high performance is due to the high-tech solutions on which the fibre laser cutter operates.

- Minimal chance of rejects. The metal laser cutter operates on a CNC (numerical control) basis, i.e. production processes such as the movement of machine components and the monitoring of emission power are controlled by digital computing devices. This reduces the human factor and the chance of error.

- Specialised programmes and functions. Thanks to the CNC, the metal laser cutter offers functions that significantly speed up and simplify the process of cutting metals.

- Service life. The fibre laser emitter of the metal laser cutting machine has a lifespan of more than 11 years. The reported service life is 100,000 hours.

- Minimal maintenance. Maintenance of the metal laser cutter is limited to regular cleaning and periodic inspection of the machine's main components.

- Consumables. The metal laser cutter does not require expensive consumables, the main ones being protective lenses and nozzles.

How a metal laser cutting machine works

First of all, it is worth knowing that to cut metals, there are metal laser cutters with a fibre optic emitter.

Conventional machines with a CO2 emitter are not capable of cutting metal; they are only designed for non-metallic materials.

The principle of operation of a fibre laser cutter can be explained as follows: the laser beam is generated in the emitter, from where it is fed through a fibre to the laser head, which is equipped with a collimator lens and a focusing lens; the focused beam hits the material and cuts through it by means of a high power spectrum with the aid of a gas which blows the molten metal out of the cutting zone.

What to produce with a metal laser cutter

The fibre laser cutting machine can cut almost any type of metal:

- carbon steel, including construction steel;

- stainless steel;

- galvanised steel;

- high-reflective metals (copper, brass, aluminium, mirror-finish stainless steel, etc.);

- titanium;

- electrical steel;

- other metals and alloys;

Metal laser cutters are used in aviation, shipbuilding, mechanical engineering, automotive industry, construction, food industry, trade, medicine, and tool making.

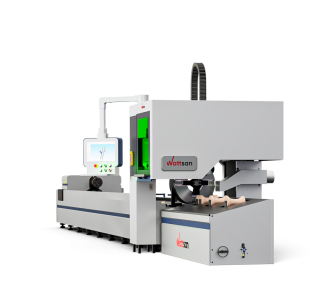

Metal laser cutting machines can cut not only sheet metal, but also round and rectangular pipes, T-beams, and I-beams. The laser pipe cutter can be a stand-alone machine or a pipe-cutting module combined with a sheet metal cutter.

Laser metal cutting is used to manufacture:

- instrument, machinery, and vehicle casings and panels;

- commercial and medical equipment;

- iron doors, facades for building cladding;

- metal furniture, racks, cabinets, shelves, stands, showcases, advertising racks;

- boxes, trays, and other metal containers;

- electrical control units;

- ventilation system elements;

- metal structures for construction;

- carved elements, fasteners;

- sheet metal perforations;

- decorations;

- all types of steel structures of simple and complex shapes made to order.

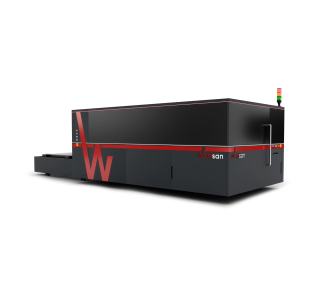

Criteria for choosing a metal laser cutting machine

The metal laser cutter is a complex piece equipment for metal cutting therefore you need to know the basic criteria that affect the quality and service life of the machine, as well as the speed of metal processing and the possible maximum thickness of the material to be processed.

Each component of the metal laser cutter must correspond to the loads received during operation.

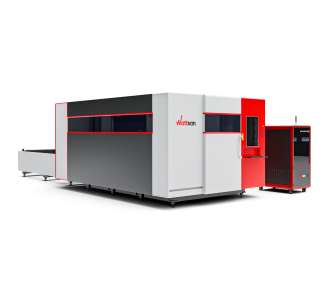

Metal laser cutter emitter

The power of the emitter of a metal laser cutter determines how much thickness and at what speed the machine can cut. The higher the speed, the faster and more efficient the metal cutting process will be.

In today's competitive market it makes sense to buy a laser machine for metal with at least 1 kW.

We supply metal laser cutting machines with Max Photonics, Raycus, and IPG emitters. To choose the suitable laser power, contact Virmer managers: +31208082045 info@virmer.com

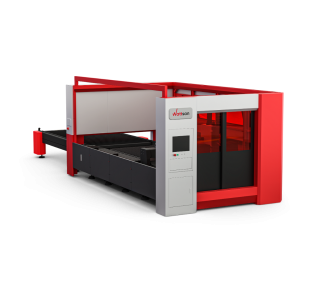

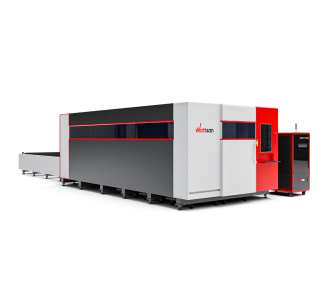

Metal laser cutter bed and frame

The stiffer the frame of the metal laser cutter, the greater the load it can withstand without vibration and the longer it lasts.

The bed must always be tempered in a furnace to release metal stress. This ensures that the geometry and precision of the machine is maintained throughout its entire service life.

Other parts of the metal laser cutter

The other most important components of the machine include:

- The gantry of a metal laser cutter must be able to withstand the stresses of starting and sudden braking, while being lightweight enough. The best solution is therefore an aluminium gantry.

- Laser head. The type of laser head depends on the emitter power and the intended application. Virmer equips its metal laser cutters with RayTools, WSX or Precitec laser heads.

- Engines affect speed, acceleration, and precision. In our catalogue, you will find laser cutters with Mitsubishi servomotors and Shimpo planetary gears.

- Guide rails and helical racks affect positioning accuracy and repeatability. These elements must be parallel and coaxial. One of the best manufacturers of guide rails is HIWIN.

Well-known component brands offer not only the assurance of high quality, but also a worldwide service.

Another important thing to consider when choosing a metal laser cutter is the reliability of the supplier. By choosing Virmer, you will get:

- Advice from a qualified technician,

- Demonstration of the equipment online or at a showroom in the Netherlands,

- EU delivery,

- Warranty and service.

For a detailed consultation or to sign up for an online demonstration, contact Virmer managers: +31208082045 info@virmer.com