Metal laser cutting is suitable for cutting sheet metal up to 80 mm thick as well as pipes of different cross-sections. Metal laser cutting is actively ousting other cutting methods from the market as the technology is developing rapidly, and the speed of metal laser cutting, the maximum possible cut thicknesses, and the efficiency of metal laser cutting machines are increasing year by year.

In this article, we will explain the basic operating principles of metal laser cutting machines, what their advantages over other metal cutting technologies are, what metals can be cut and what can be manufactured using metal laser cutting, and how various models of metal laser cutting machines differ.

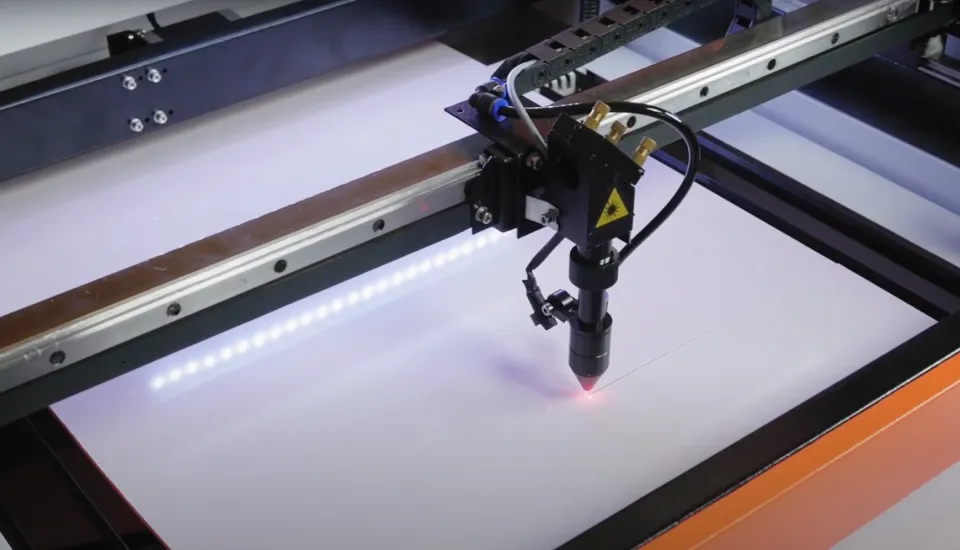

Operating principles of metal laser cutting

Modern metal laser cutting machines use a fiber optic laser source as the emitter. The generation process takes place in the pump diodes by means of a resonator, and then the laser beam is fed through an optical fiber to the laser head of the metal laser cutting machine, where a collimator and a focusing lens are located.

The focused laser beam has a high power density due to its monochromaticity and coherence.

Monochromaticity means that the spectrum of wavelengths emitted is so narrow that the photons of laser radiation can be said to have the same or close to the same wavelength.

Coherence refers to the coherence of the wave motions of a laser. Temporal coherence ensures the consistency of oscillations at the same point in space at different times, while spatial coherence ensures that the laser radiation is unidirectional and that the diffraction limit, i.e. the minimum value of the laser beam spot emitted by a metal laser cutting machine, is reached.

It is thanks to this that a metal laser cutter is able to focus to a point 0.01mm in diameter with a power density of 10¹³W or more, which allows the laser radiation to heat metal to a melting point at an area 8 times smaller than a human hair in a fraction of a second.

Metal laser cutting is divided into two basic methods: fusion cutting and sublimation cutting.

Laser fusion cutting of metals

The high power density of the laser beam instantly melts the metal while an auxiliary gas is supplied to the cutting zone, which blows the molten material away and can also cool the area around the cutting zone.

Laser sublimation cutting of metals

This method is more commonly used in micro engineering for laser cutting of thin metals. It is very energy intensive as high-powered nanosecond lasers are used to vaporise the material without deformation. The efficiency is 5-8 times lower than in laser fusion cutting of metals.

Advantages of laser cutting over other metal cutting methods

Laser cutting of metal is one of the youngest, yet most advanced methods of cutting sheet metal and pipes. It has the following advantages:

- No waste in the form of swarf, metal dust or cutting aids such as sand when using waterjet cutting;

- Easy and safe operation of the metal laser cutting machine. No need for specially equipped room and protective suits;

- High precision laser cutting of metal. Laser diameter up to 0.01 mm, repositioning accuracy - 0.02 mm;

- The material is not deformed. The heat-affected zone is so small that when metal is laser-cut, it does not have time to heat up enough;

- Perfectly clean cut. After laser cutting, the metal does not need any post-processing, there are no burrs or dross on the cut face, and the finished product often goes into work without any post-processing;

- Metal laser cutting of complex designs. Unlike, for example, band saw cutting, a laser can cut contours of any complexity;

- Operation speed. Wattsan metal laser cutting machines reach speeds of up to 60 m/min when laser cutting metals, especially thin sheet metal. And idle speeds of up to 140 m/min;

- Service life. The life expectancy of a metal laser cutting machine is more than 11 years;

- Computer numerical control. The machine's control system does most of the metal laser cutting, and this ensures complete product consistency and reduces inaccuracies and rejects to a minimum;

- Easy to learn. The basic principles of metal laser cutting and working with a metal laser cutting machine can be learned in one working day.

- Machine versatility. The time to launch a new product can take minutes; during operation the product configuration can be changed by the operator to suit the task.

- No consumables. In the operation of a metal laser cutting machine, consumables are either non-existent or of low cost. The main consumption is the material and auxiliary gases.

Laser cutting of metals. What metals can be cut

The following metals are suitable for laser cutting:

- carbon steel,

- galvanised steel,

- alloyed steel,

- stainless steel,

- copper,

- brass,

- aluminium,

- titanium.

If a metal laser cutting machine is equipped with a special unit, it can cut not only sheet metal, but also round and rectangular pipes. There are also specialised machines for laser cutting of metal pipes.

Air or oxygen is used for laser cutting of ferrous metals. Laser cutting of metal with air requires a compressor, and with this method, you can cut relatively small thicknesses up to 3-5 mm. But with enough laser source power the maximum material thickness can be up to 20 mm. Laser cutting of metal with oxygen makes cutting several times faster.

Inert gases, most commonly nitrogen, are used for the following tasks:

- for laser cutting of metals that have rust-proof properties in order to preserve them;

- for laser cutting of metals with high thermal conductivity, copper and aluminium, to avoid dross build-up;

- titanium requires argon for cutting because after cutting with other gases this metal becomes porous and brittle.

A metal laser cutting machine is not well suited to cut wooden materials. Moreover, it would be an unviable solution, as CO2 machines are ideal for wood-based materials, and they are considerably cheaper than metal laser cutting machines.

For more details on choosing a metal laser cutting machine, contact Virmer managers: +31208082045, е-mail: info@virmer.com.

Metal laser cutting applications

Metal laser cutting is used in shipbuilding, aircraft and machine construction, automotive manufacturing, construction, instrumentation, medical and food industries.

What can be manufactured using metal laser cutting machines?

- metal structures for construction and cladding of buildings;

- iron doors and metal furniture;

- storage furniture: racks, cabinets, shelves, drawers, trays;

- advertising constructions: signboards, display letters, stands, showcases, advertising racks;

- equipment housings and panels;

- ventilation systems;

- mounting hardware;

- equipment and furniture for medicine and trade;

- decorative outdoor grills;

- exterior and interior design, such as customized metal gates;

- laser cutting of metal elements of any complexity;

- any custom-made metal structures.

What is the difference between metal laser cutting machines

The Wattsan metal laser cutting machines on our website can be divided into 3 main categories: E-line, S-line, and HARD-line. The E and S lines are available in working area sizes 1300x2500 mm and 1500x3000 mm, while the HARD-line has sizes 1500x3000, 4000x2000, and 6000x2000 mm.

The main difference between the three models is the maximum power of the laser source, the design of the housing, and the components. This, consequently, determines the performance and the maximum possible thickness of the material to be cut.

In terms of what these models have in common, the following points can be highlighted:

- These metal laser cutting machines are designed for round-the-clock operation;

- All-welded frame is reinforced with internal fins every 400 mm;

- Laser sources from leading manufacturers: IPG, Raycus, MaxPhotonics, JPT;

- Robust and lightweight aluminium gantry;

- HIWIN guide rails and LEAN B2 helical racks;

- Metal cover of the guide rails saves from sparks and burning through the corrugated protection;

- Mitsubishi engines with Shimpo gearboxes; different models have different output depending on loads;

- Siemens electrics;

- FSCUT controller;

- The CYPCUT software features remote system diagnostics as well as a number of features that speed up and simplify metal laser cutting;

- The zone fume extraction system is more efficient and economical because it only works in the segment of the machine where metal is being cut.

Now, let us take a closer look at the differences between the Wattsan E-line, S-line, and HARD-line of metal laser cutting machines.

Wattsan E-line metal laser cutting machines

This is the basic model of metal laser cutting machine, and it is more suitable for high-speed laser cutting of thin metal. Features of the E-line:

- Suitable for laser cutting of metals up to 4 mm thick;

- Equipped with IPG, Maxphotonics, JPT or Raycus laser source with a power rating of 1000, 1500 or 2000 W;

- Travel speeds of up to 80 m/min at an acceleration from 1G;

- The all-welded frame has a section of 6-8 mm;

- 1 kW Mitsubishi engines and Shimpo gearboxes;

- X- and Y-axis: HIWIN 20 mm guide rails and Lean B2 helical racks;

- Z-axis: HIWIN 15 mm guide rails and 16 mm ball-and-screw;

- As standard, available with RayTools laser head, optional with WSX or Precitec laser head.

For more details about such a metal laser cutting machine, see the Wattsan 1325 E.

Wattsan S-line metal laser cutting machines

Designed for high speed and high precision laser cutting of medium thickness metals. Features of the S-line metal laser cutting machines:

- Suitable for laser cutting of metals up to 12 mm thick;

- Equipped with IPG, Maxphotonics, JPT or Raycus laser source with a power rating from 1000 W to 6000 W;

- Travel speeds of up to 140 m/min at 2G acceleration;

- The all-welded frame has a section of 8-12 mm;

- 2 kW Mitsubishi engines and Shimpo gearboxes;

- X- and Y-axis: HIWIN 20 mm guide rails and Lean B2 helical racks;

- Z-axis: HIWIN 15 mm guide rails and 16 mm ball-and-screw;

- As standard, available with RayTools laser head, optional with WSX or Precitec laser head.

For more details, see the Wattsan 1530S.

Wattsan S-line metal laser cutting machines can also be equipped with interchangeable tables, a pipe-cutting unit, and a protective cabin.

Interchangeable tables

The Tablechange saves time by ensuring that while one table is used for laser cutting of a metal sheet, the operator removes the cut pieces and lays out a new sheet of material on the other. The automatic table change takes 18 to 30 seconds.

For example, the Wattsan 1530 Tablechange metal laser cutting machine.

Pipe cutting unit

It is mounted directly next to the machine. It allows for cutting both sheets of metal and metal pipes. For example, the Wattsan 1530 Rotatory metal laser cutting machine.

The Wattsan 1530 Rotatory cuts circular pipes up to 220 mm and rectangular pipes up to 160 mm with a length from 3 to 9 metres. Permissible dimensions for laser sheet metal cutting: 1500x3000 mm.

Protective cabin

It is designed for safety when using medium and high power laser sources. Completely encloses the working area of a metal laser cutting machine and has viewing windows to protect against reflected laser beams and sparks.

Optional accessories can be combined with each other or fitted all at once, as on the Wattsan 1530 Tablechange Rotatory Cabine laser metalworking machine.

Designed for cutting particularly thick metals. Equipped by default with interchangeable tables because this type of laser metal cutting machine initially involves a large workload. Features of the HARD-line:

- Suitable for cutting metals up to 80 mm thick;

- Equipped with an IPG laser source from 3000 to 20000 W;

- Travel speeds of up to 140 m/min at 2G acceleration;

- The all-welded frame has a section of 15-18 mm;

- The machine frame is protected by a graphite and ceramic coating and copper plates to reflect and level out thermal effects;

- 16 mm thick reinforcing fins around the perimeter inside the frame;

- Fully enclosed housing design with air filtration system;

- 1.3 kW Mitsubishi engines and Shimpo gearboxes;

- X- and Y-axis: HIWIN 30 mm guide rails and Lean B2 helical racks;

- Z-axis: HIWIN 25 mm guide rails and 25 mm ball-and-screw;

- Increased cross-section of aluminium gantry;

- Comes with Precitec laser head by default;

- Equipped with two cameras: for observing work inside the machine and for observing the interchangeable tables;

- Separate electrics cabinet for easy access.

Difference between fiber and CO2 metal laser cutting

Since we are writing about metal laser cutting, we cannot fail to mention that some CO2 machines are also suitable for this purpose. For example, the Wattsan NC-1612, which can also cut non-metallic materials.

The laser tube power of this machine is 130-150 W and the size of the working area: 1600x1200 mm. This versatile machine cuts metals up to 1,5 mm thick as well as any other standard materials for CO2 lasers: plywood, veneer, MDF, wood, plastics, textiles, leather, and fur.

Read more about the Wattsan NC-1612 metal laser cutting machine on our website.

Conclusions

A metal laser cutting machine is the most productive tool for cutting sheet metal and pipes. The price of any metal laser cutter depends on the power of the emitter and a number of other parameters.

To book an appointment for a consultation or an online demonstration of metal laser cutting machines, contact Virmer managers: +31208082045, е-mail: info@virmer.com.