Paper and cardboard are inexpensive but practical materials that are used in advertising, in production of packaging and various printed products, and even for technical purposes, for example, for cutting gaskets and inserts.

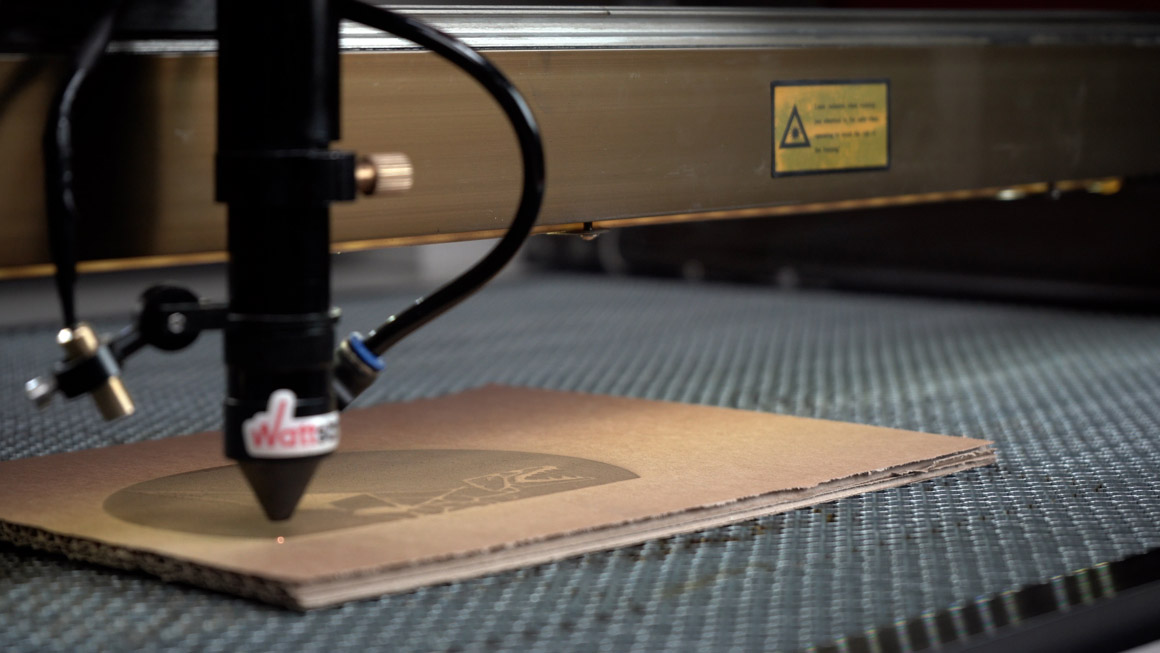

Paper materials are made from organic fibers, which are easily amenable not only to printing and embossing, but also to laser cutting, engraving and marking.

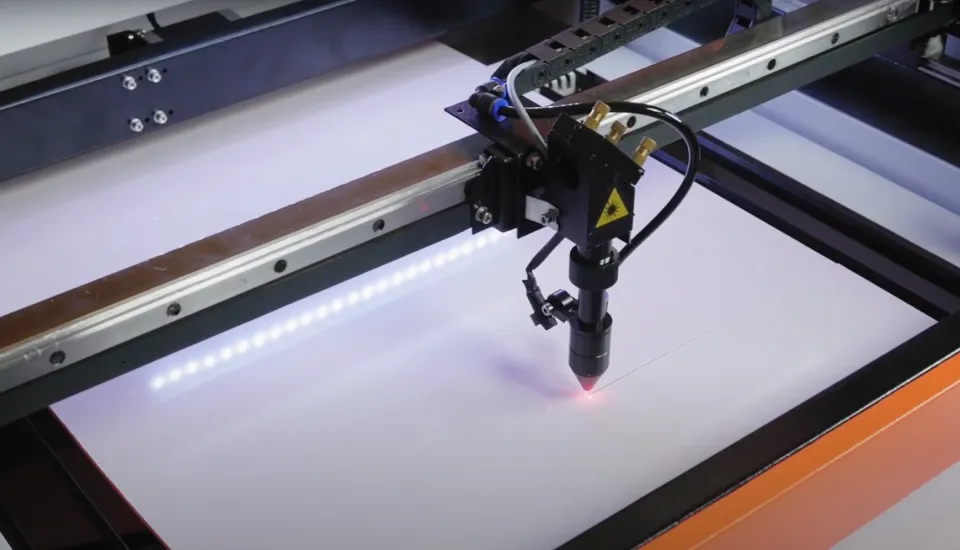

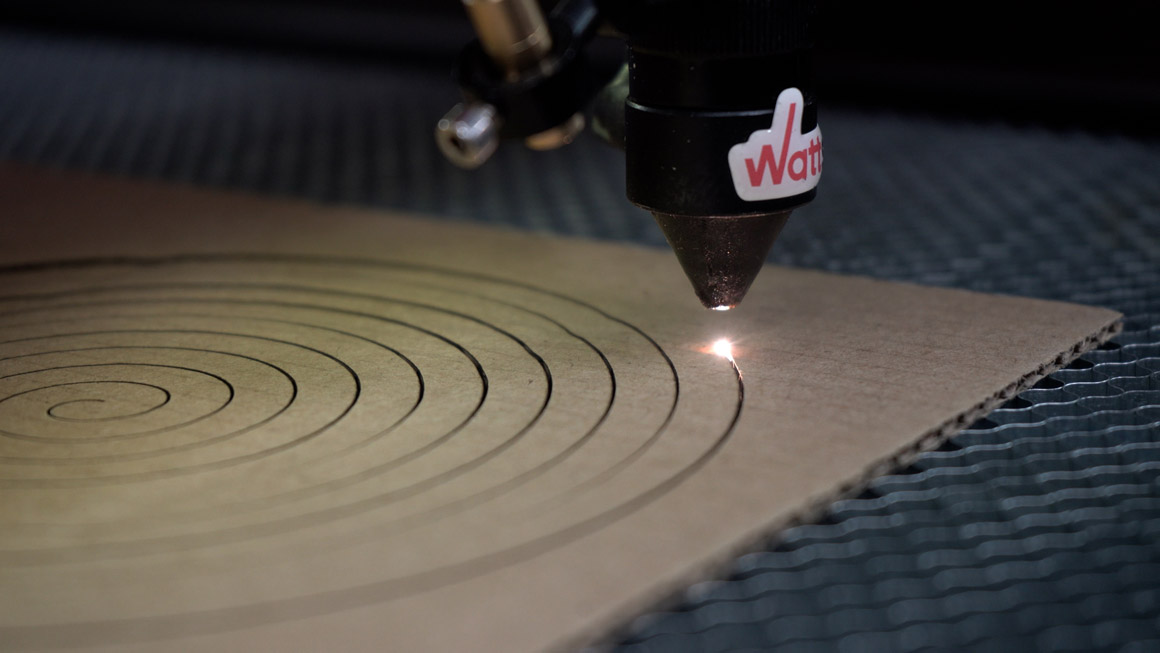

CO2 laser machines are an ideal tool, as they are able to quickly cut and engrave paper and cardboard according to vector drawings and raster images of any complexity. All you need is to load the layout of the drawing into the machine, select the speed and power indicators and press the "start" button.

In this article you will learn:

- what can be made from paper and cardboard using a CO2 laser machine,

- what types of paper and cardboard are suitable for laser cutting, engraving and marking,

- what are the advantages of laser treatment of these materials,

- what to pay attention to when choosing a laser machine for cutting cardboard and paper,

- which laser machines to choose for certain tasks

What can be made from paper and cardboard using a CO2 machine?

With the help of a CO2 laser machine, you can cut paper and cardboard, as well as apply laser engraving on these materials.

Laser cutting of paper and cardboard

CO2 laser cutting machines allow:

- laser cut out of paper and cardboard any layouts, including complex high-precision patterns, such as lace or detailed patterns,

- make laser perforation of paper or cardboard,

- using the camera to determine the contours of already printed images and cut them with a laser.

Laser machines for paper and cardboard can be used to cut out final or intermediate products that require further assembly or processing. With the help of laser cutting of paper and cardboard, the following can be produced:

- Children's books, stencils, crafts;

- Puzzles, constructors, puzzles, prefabricated models;

- Original packaging and boxes;

- Postcards, invitations, booklets, business cards, printing products;

- Elements of decor and interior and exterior decoration;

- Industrial gaskets and inserts;

- Patterns.

Laser engraving and marking of paper and cardboard

Strictly speaking, it will not work to make laser engraving on paper, since it is still the removal of a certain layer of material from its surface, and it is almost impossible to achieve this on paper without destroying it. But light engraving can be done on cardboard, as it is more dense. But the paper can be marked with a laser.

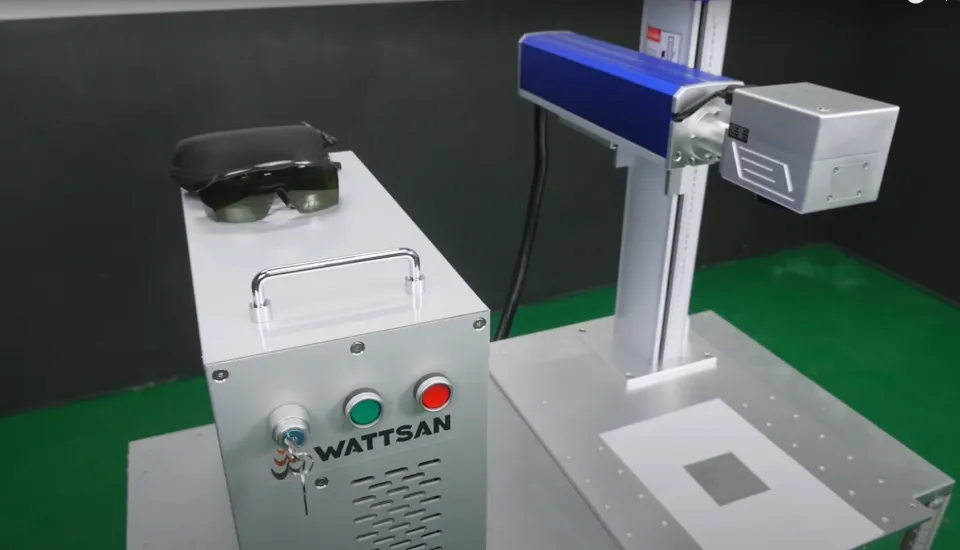

If you only need laser marking of paper, not cutting, pay attention to CO2 laser marking machines. Unlike laser engravers and cutters, they are more accurate and faster at marking paper. Examples of such laser markers for paper and cardboard:

Marking speed: up to 7000 mm/s.

Power: 50-80 W

Price: from 3649 €

Marking speed: up to 5000 mm/s.

Power: 30-50 W

Price: from 7542 €

The dimensions of the working field of laser markers on paper and cardboard depend on the lens used. The maximum size of the working field: 300x300 mm. For advice and detailed specifications, please contact Virmer managers: +31208082045 or е-mail: info@virmer.com.

Which paper and cardboard are suitable for laser processing?

With the help of a CO2 laser machine, you can cut almost any kind of paper and cardboard:

- Craft, matte, chalk-coated, designer, offset, newsprint, coated or embossed paper;

- Standard cardboard, cardboard of various densities, packaging, printing, designer, chipboard, beer, combined cardboard;

- Corrugated cardboard, including multilayer and laminated;

- Foam board, including self-adhesive.

It will be difficult to make laser marking on low-density paper.

Advantages of laser cutting of paper and cardboard on a CO2 machine

Laser machines for cutting paper and cardboard have taken a reliable position in the production processes associated with these materials. This is due to the following advantages of laser machines for paper and cardboard:

- High quality. The edges of the cut materials are not deformed or damaged, unlike, for example, after stamping. And thanks to the accuracy of work up to 0.03 mm, laser machines on paper and cardboard can cut highly detailed patterns and miniature holes with a minimum radius of edges and get a clear joint of products in the necessary places;

- High speed operation. CO2 laser machines achieve cutting speeds of 500 mm/s and engraving speeds of 700 mm/s. CO2 laser markers are capable of marking and engraving at a speed of 7000 mm/s;

- There is no tool wear. The quality of laser cutting remains at a high level throughout the life of the laser tube, which is up to 10,000 hours of continuous operation. The laser beam doesn't become blunt, unlike knives and blades.

- Non-contact cutting. There is no need to fix the cut blanks, there is no possibility of reject due to the rupture of cardboard sheets under physical influence. In addition, the material does not need to be fixed if it is smooth enough, and this saves time during operation;

- Flexibility. Laser cutting requires a vector layout, which can be easily adjusted. Creating a layout does not require a lot of time and money, unlike the production of molds for analog cutting machines, so laser machines on paper and cardboard can also be used for small batches. Laser machines on paper and cardboard are compatible with CAD systems, which designers will appreciate;

- Simplicity. Laser equipment is easy to maintain, and it will take no more than one day to learn the basics of work;

- Computer Numerical Control. The entire cutting process is carried out by means of a laser machine controller on paper and cardboard, this eliminates the human factor, possible errors and guarantees the identity of products in mass production.

Which laser machine for paper and cardboard to choose

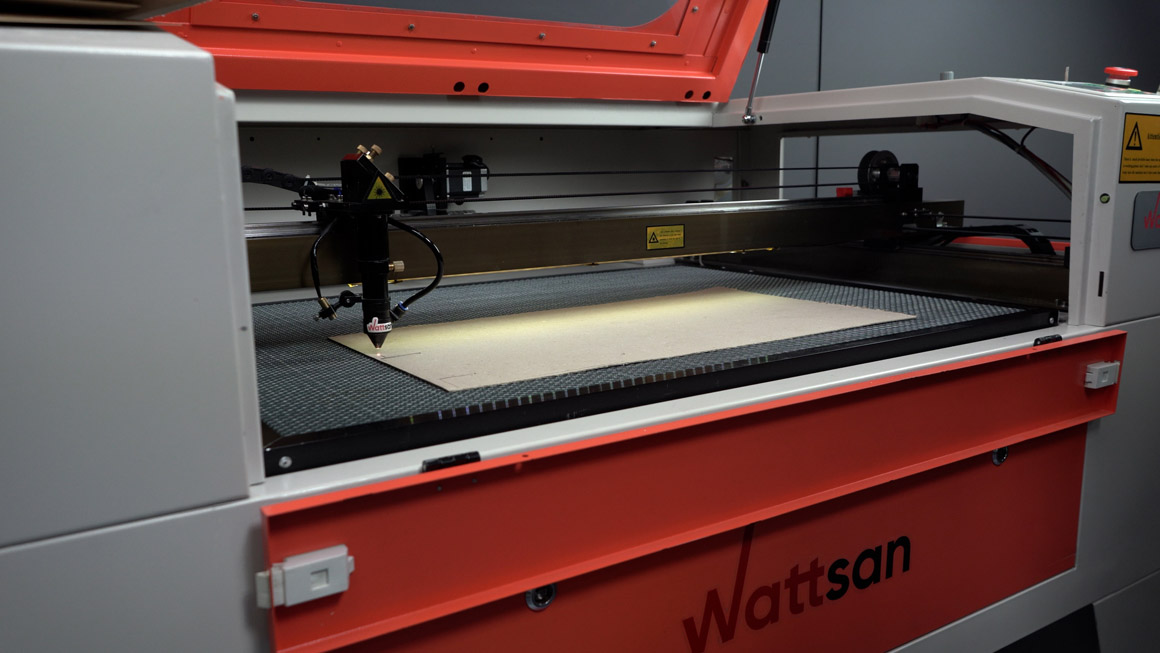

Cutting cardboard and paper with a laser is not the most difficult task, especially if it is performed on a good CO2 laser machine. The components of the machine affect the quality and speed of cutting, vibration damping from inertial loads and the durability of the equipment itself.

In addition to the main indicators, such as the size of the working table and the power of the laser machine, it is necessary to take into account the presence or absence of certain functions in order to choose the ones you need and not overpay for the extra ones.

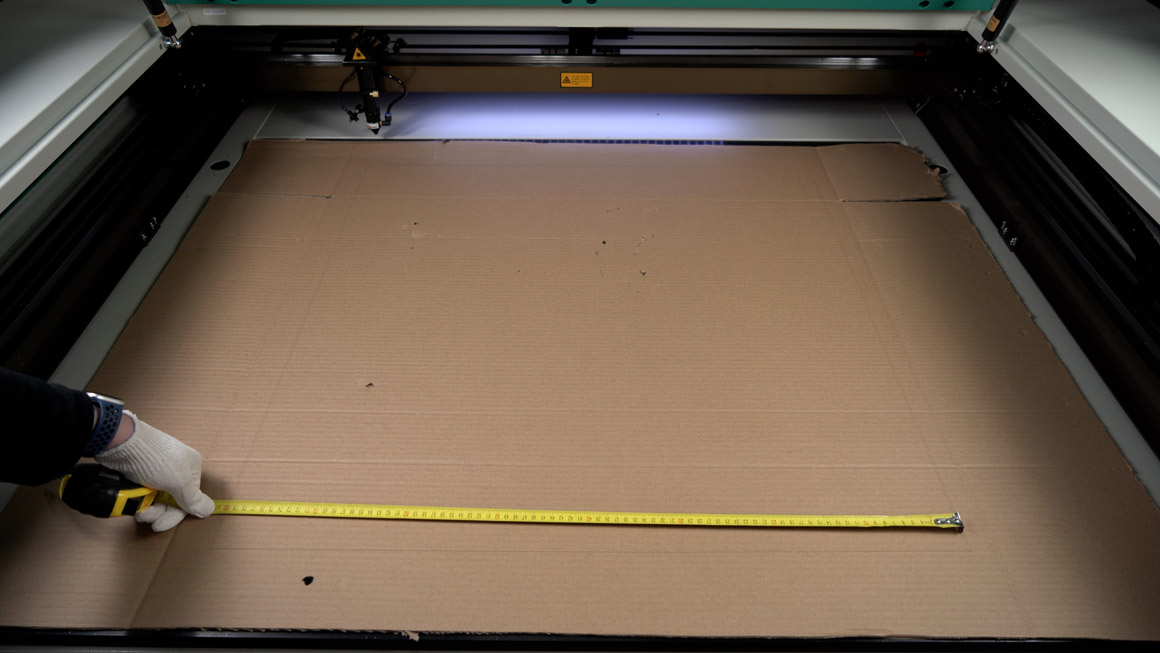

The size of the working field of the laser machine on paper and cardboard

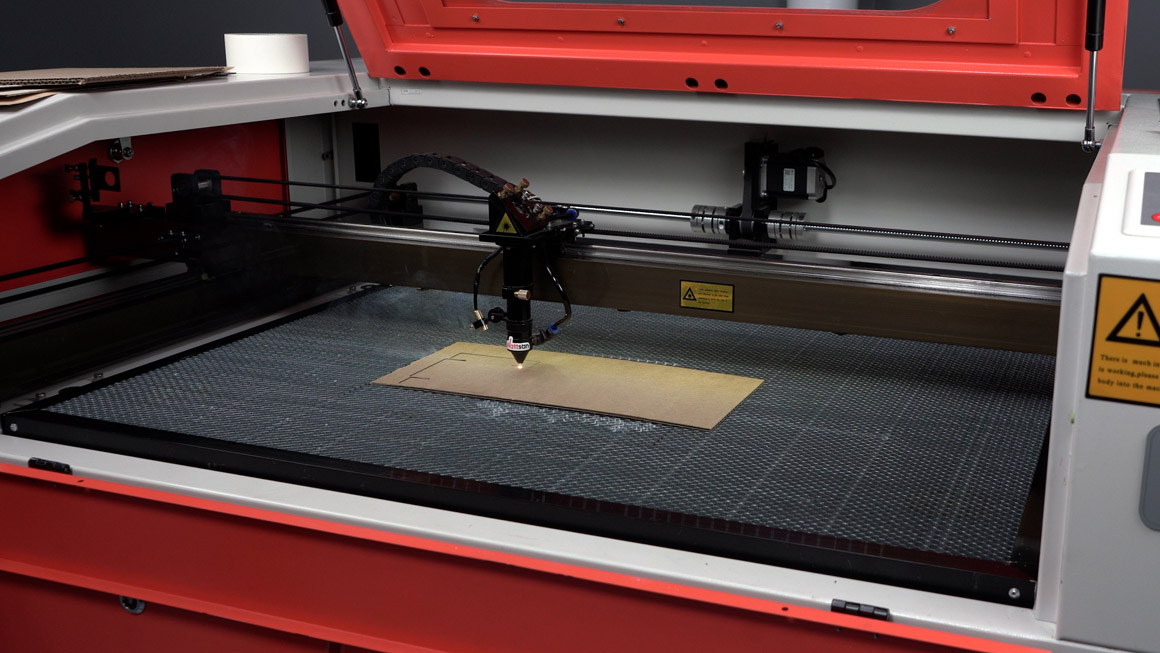

The required size of the working field depends on what you will do — if it's postcards, the desktop Wattsan 0503 will be enough. If you have to make packaging, for example, corrugated cardboard boxes, then you need to take into account that unfolding of such boxes can be very large and will fit only on large-format machines, such as Wattsan 2030 FlatBed.

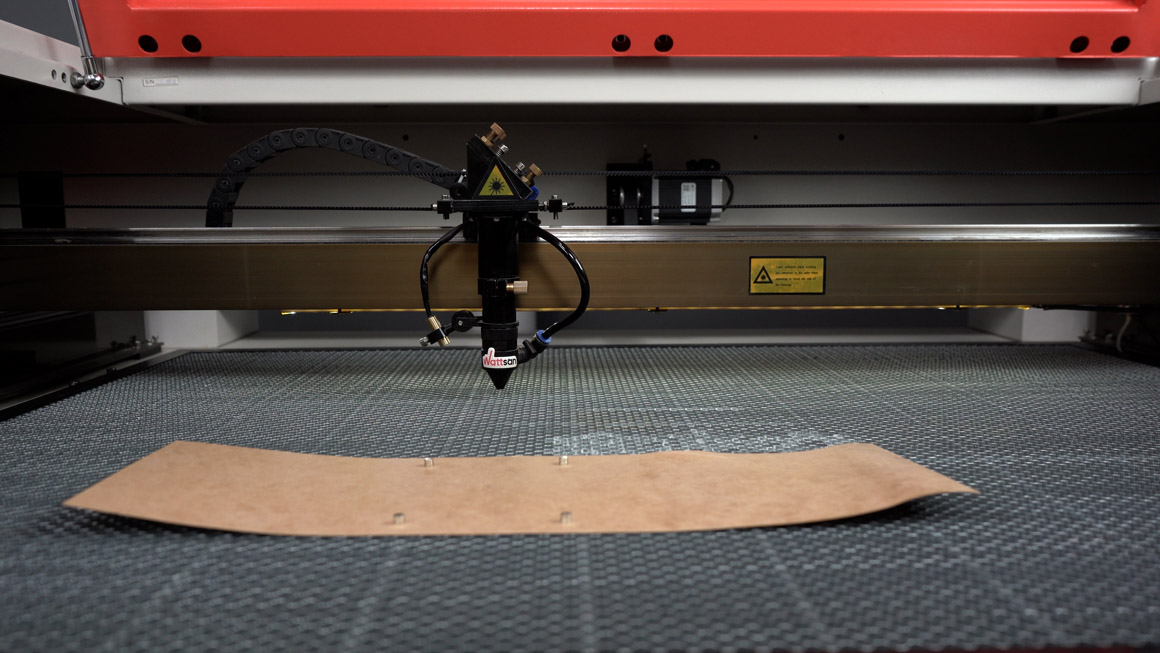

View of the working table of the laser machine on paper and cardboard

For laser cutting of paper and cardboard, a cellular table is better suited, not lamellas. Its advantage is that you can use neodymium magnets to press the material if it is not smooth.

Also pay attention to the presence of a through hole at the level of the working table in the housing. It is useful for working with materials of any length, if they are placed on the table in width — you can stretch the material through the machine.

The lifting table function, which is designated as "LT" in Wattsan machines, is not needed for laser cutting of paper and cardboard. Therefore, we recommend paying attention to laser machines with a static table, they are designated as "ST".

The body and mechanics of the laser machine on paper and cardboard

The frame of a laser machine for cutting paper and cardboard affects the vibration resistance of the structure and the overall service life of the machine. Vibrations during operation reduce the quality of the final result — the cutting lines are uneven, the contours of the laser engraving are broken.

Give preference to laser machines with three-phase motors, as they have a smaller angular pitch, which means greater accuracy and smooth running. If the engines are equipped with gearboxes, this will be another advantage, since the gearboxes increase the operating resolution and relieve the load from the engines themselves.

In order to maintain the accuracy of work during the entire service life, a laser machine on paper and cardboard must have a high-quality portal. For example, Wattsan machines have a reinforced aluminum portal with a cross section of 7 mm at the corners.

Power

On the one hand, there is no need for high-power laser tubes for laser cutting of paper or cardboard, you can do with a laser emitter with a power of 50-60 watts. On the other hand, a more powerful laser tube cuts at a higher speed.

If your priority is laser cutting, and not engraving or marking, pay attention to laser tubes with a nominal value of up to 100-120 watts. Such tubes will allow you to easily and quickly cut through with a laser not only paper and ordinary cardboard, but also multilayer corrugated cardboard or thick foam cardboard.

For laser engraving, there is no need for high power, especially for such thin materials as paper and cardboard, since high-power laser machines will burn through these materials even at the lowest power settings.

For laser marking and engraving of paper and cardboard of small size, Wattsan Co2 LT laser markers are better suited and Wattsan RF DAVI, which we mentioned above.

Potentiometer

For laser engraving of cardboard and paper marking, it is important to have a potentiometer in the configuration of the laser machine. The potentiometer helps to manually fine-tune the power to achieve perfect results.

If you want to learn more about choosing a laser machine, read our article "How to choose a CO2 laser machine" or contact the Virmer managers: +31208082045 or е-mail: info@virmer.com. We can conduct an online demonstration, as well as send a Virmer engineer to you for commissioning and training.

The best laser machines for cutting, engraving and marking paper and cardboard

Which laser machine will be the best for you directly depends on the purpose of its use. Below we have selected the best machines for different tasks.

Wattsan 0503

It is ideal if you need to combine laser cutting, laser engraving and marking of paper and cardboard of small sizes.

Working field: 500x300 mm

Power: 60W;

Cutting speed: up to 500 mm/s;

Engraving speed: up to 700 mm/s.

Price: from 3265 €

Actual price and detailed information.

Wattsan 1290 Duos ST

Suitable for high-performance laser cutting of paper and cardboard of size up to and including A0 (1189 x 841 mm). Equipped with two laser heads working simultaneously.

Working field: 1200x900 mm

Power: 100-120 W;

Cutting speed: up to 500 mm/s;

Engraving speed: up to 700 mm/s.

Price: from 7386 €

Actual price and detailed information.

Wattsan 1610 Cam Conveyer

Equipped with a Canon camera that scans and recognizes contours. Suitable for laser cutting of paper and cardboard with prints.

Working field: 1600x1000mm

Power: 100-120 W;

Cutting speed: up to 400 mm/s;

Engraving speed: up to 600 mm/s.

Price: from 15799 €

Actual price and detailed information.

Wattsan 2030 FlatBed

Suitable for cutting large-format sheets up to 4A0 (2378 x 1682 mm) and sheets of non-standard sizes.

Working field: 2000x3000 mm

Power: 100-120 W;

Cutting speed: up to 350 mm/s;

Engraving speed: up to 500 mm/s.

Price: from 16747 €

Actual price and detailed information.

Conclusions

Laser machines are capable of processing almost any kind of paper and cardboard, the main thing is to choose the right model for your tasks. If you need help in choosing, please contact Virmer: +31208082045 or е-mail: info@virmer.com