So, you have decided to engage in laser engraving. The first question is, what kind of machine is required for this? The abundance of laser engraving machines on the market can scare and confuse. Which laser engraver is more suitable for wood engraving, which one is for metal work, and which one is for plastics?

Before buying such expensive equipment, you should figure out how it works, what it is capable of, how it differs from each other and what parameters are important to take into account when choosing to avoid any mistake. And for answering all these questions, we have written this article.

TABLE OF CONTENT:

- What is laser engraving?

- What can be made using laser engraving?

- Top laser engraving machines for:

- plywood and wood materials,

- metals,

- plastics,

- other materials (glass, leather, stone, ceramics, textiles),

- the best engravers for business and production lines

- Differences between laser engravers

- Types of laser

- Design and principle of operation

- How to choose a laser engraver - the main criteria

- Conclusion

What is laser engraving?

Laser engraving is a method of applying graphic information (images or inscriptions) to a material or product with a focused laser beam. The laser burns the surface layer of the material at the points specified by the control program.

Advantages of laser engraving:

- operating speed from 500 mm/s to 7000 mm/s, depending on the machine,

- permanent image is indelible, resistant to physical and chemical influences,

- the laser works contactless, so it does not leave chips and cracks on the material, unlike other processing methods,

- the laser beam diameter at the focus point reaches hundredths of a millimeter, which makes it possible to engrave miniature complex images with a high degree of detail,

- CNC (computer numerical control), when properly configured, excludes defects during operation,

- cylindrical objects can be processed using a rotary device,

What can be made using laser engraving?

Laser engraving machines are a popular tool for applying images and inscriptions. They are used for:

- application of barcodes and QR codes (with laser markers), technical or general information about the product, branding of products and packaging, application of logos, decoration of interior items and household items (for example, it is often used in restaurants to apply images to serving boards, napkin holders, badges and other items),

- creation of souvenir products, including personalized gifts and engraving on phone cases,

- engraving of production runs of standard products (wooden rulers, toppers, toys and prefabricated models, etc.),

- engraving of leather goods, stone or glass (including engraving on glasses)

Top laser engraving machines

The best machines for engraving plywood, wood and wood materials (chipboard, MDF, cardboard, cork, etc.)

Laser CO2 Engraver Wattsan 0503

Working speed 500 mm/s, power 60 W, working field size 500x300 mm. The machine is designed specifically for engraving: a short-focus lens gives a smaller diameter of the laser spot, and an expanded nozzle reduces the force of blowing - thanks to this, combusiotn products do not stick to the material surface and the engraving becomes cleaner. The working table has a lifting mechanism with 200 mm stroke, which allows you to use a rotary device and engrave large objects and workpieces. The engraving resolution is up to 2500 dpi.

The machine price is about 3 265 €, you can find the actual price on our website.

Also pay attention to the master model – the Wattsan 6040 CO2 laser engraver, with an increased working field size of 600x400 mm and an increased power of 90-100 watts. The machine price is about 4 319 €, please check the actual price on our website.

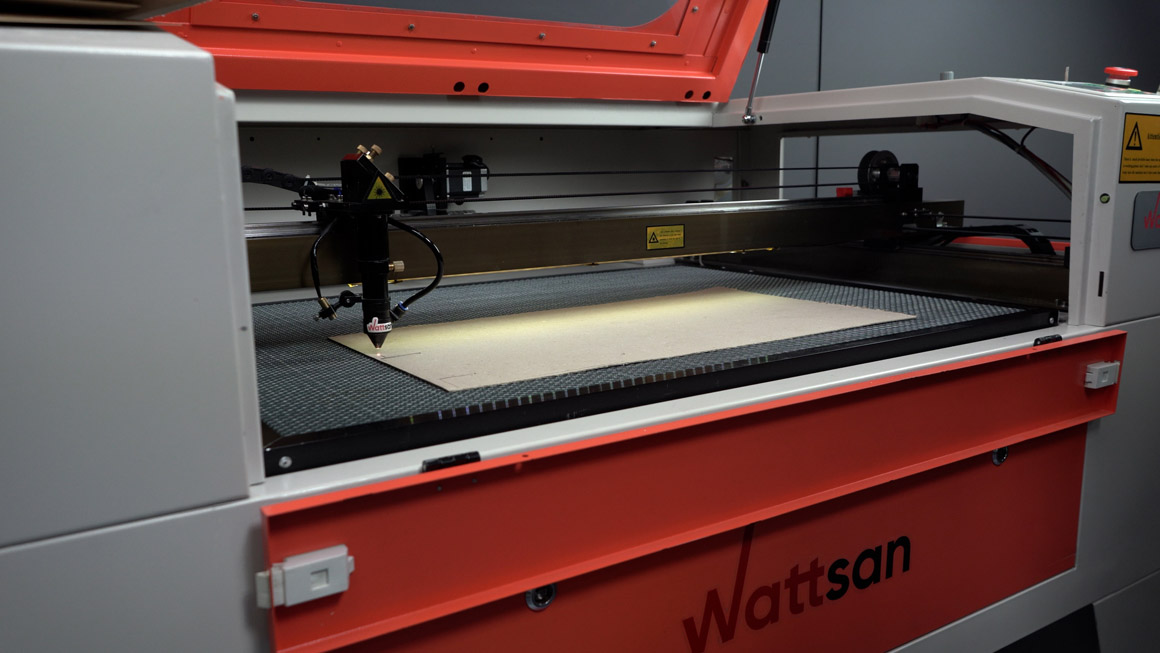

CO2 Laser machine Wattsan 6090 LT

This is one of the most popular models, designed for both engraving and cutting material. A 600x900 mm through table allows you to pull large sheets of material through if its width does not exceed 900 mm. The working table is lowered by 160 mm, applicable for rotary device installation. The reinforced machine body dampens vibrations during cutting and engraving.

The machine price is about 5 213 €, please check the actual price on our website.

Laser CO2 marker Wattsan CO2 LT

The laser marker has a smaller working field size: from 110x110 mm to 300x300 mm, but its working speed reaches 7000 mm/s. Suitable for high-speed engraving of small products or workpieces. It can be equipped with a rotary device.

Please check the actual price on our website.

The best metal engraving machines (carbon or stainless steel, aluminum, copper, precious metals)

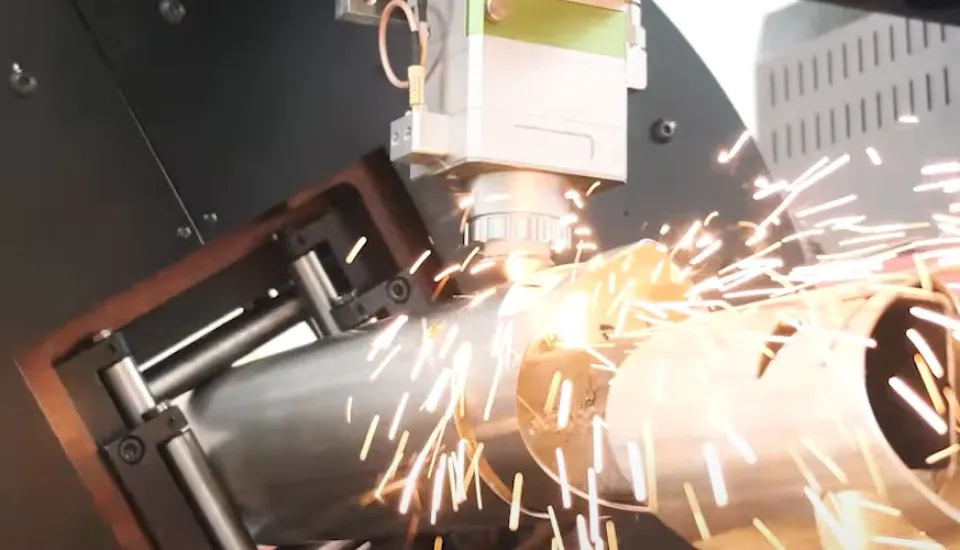

Fiber laser marker Wattsan FL TT

The working field is from 110x110 to 300x300 mm, the working speed is up to 7000 mm / s, the machine can be equipped with a fiber optic emitter with a power from 20 to 100 watts, accuracy is up to 0.03 mm. The service life of the emitter is 100,000 hours, i.e. over 11 years, while the machine does not require consumables.

Please check the actual price on our website.

A similar fiber-optic laser marker Wattsan FL LT has a different table design and a different way of focusing, the approximate price is 4,300 €, please check the actual price on our website, for a detailed consultation, please contact our managers, phone: +31208082045 or email us at info@virmer.com.

Fiber-optic laser marker Wattsan FL HH

This machine is equipped with a manual portable scanner with a fiber length from 5 to 10 meters, which allows you to take it in your hands and engrave on both horizontal and vertical surfaces and even on the ceiling. The Wattsan FL HH laser marker is designed for engraving in hard-to-reach places or on dimensional objects - large parts and mechanisms, barrels, containers and machines. This laser marker is equipped with a special focusing frame, which is fixed on the scanner and helps not to lose the focal length during operation.

Please check the actual price on our website.

The best engravers for business and production lines

Fiber-optic laser marking station Wattsan FL ST

This station marks and engraves metals, plastics, leather and leatherette, as well as ceramics and stone. The marking station, unlike conventional markers, has a monolithic housing with a convenient desktop with control buttons, all the electrics of the machine are located inside the housing. Such a machine can be easily integrated into a production line or used as a stand-alone machine.

The machine price is about 4 066 €, please check the actual price on our website.

Two-head CO2 laser machine Wattsan 1290 DUOS LT

Speeds up the work twice, as it has two working heads at once, which operate simultaneously. The working field of 1200x900 mm allows you to produce more products in one run of the control program than on machines with a smaller working field. Ideal for a regular 24/7 load, used for both engraving and cutting.

The machine price is about 7 876 €, please check the actual price on our website.

Differences between laser engravers

A laser engraver is any laser machine that is capable of performing the function of engraving. But all these machines can be divided into two main groups based on the following features:

- Emitter type: CO2, fiber optic or UV,

- Construction: portal type machines or markers with sino-galvo galvanometric scanners.

Type of laser marking machine emitter

The type of emitter depends on what material the machine is able to work with.

This is justified by the fact that laser radiation can have different wavelengths, and different laser waves have different ability to affect materials.

There are three main types of laser emitters – ultraviolet (UV), carbon dioxide (CO2) and fiber optic.

UV Laser markers

Ultraviolet emitters have a wavelength of 355 nanometers. Most often, only low-quality cheap UV engravers can be found on the market of laser engravers. Their price ranges from hundreds to several hundred euros, and the result is always the same — their maximum performance is pokerwork with your child.

But at the moment, UV laser technology is actively developing and some companies, such as IPG, propose truly unique UV laser equipment that can work with almost any materials, but their main disadvantage is the price, which exceeds the cost of similar equipment with other emitter types by 5-10 times.

And we recommend not even wasting your time on low-quality UV laser markers, since they have a weak effect, low productivity and poor quality of the laser beam.

CO2 Laser Engravers

The wavelength of CO2 emitters can be 10600 or 9400 nanometers, this allows you to engrave wood and all wood materials, including plywood, MDF, paper and cardboard, as well as most plastics, leather and leatherette, mirror and glass, stone and ceramics.

In order to get a result similar to metal engraving on a CO2 laser engraver, a special paste is used, which is pre-applied to the material. But the engraving in such cases turns out to be of poor quality and very unreliable.

There are also hybrid CO2 laser machines that are capable of processing both metals and non-metals. But they have a high laser tube power – from 130W to 180W, so they are more suitable for cutting materials than for engraving. In addition, they still can engrave non-metals only, and metals can only be cut with their help.

Fiber Laser Engravers

More often they are called laser markers. Fiber-optic laser machines are designed for:

- metal working: ferrous metals, stainless steel, aluminum, precious metals, titanium and others,

- you can engrave most plastics: acrylic, ABS, soft-touch, polypropylene, rubber, double-layer plastics and others,

- stone and ceramics,

- leather and leatherette, some types of textiles.

Depending on your tasks and the materials that you plan to process, you should decide which type of emitter you need: UV, CO2 or fiber optic. As our practice shows, most often people choose between CO2 and fiber.

Now it is worth discussing such an important parameter as the design and principle of operation of the laser machine, because this directly affects the speed of the machine and its functionality.

Design and principle of operation

There are two main construction types of laser engraving machines — machines with flying optics and markers on galvanometric scanners.

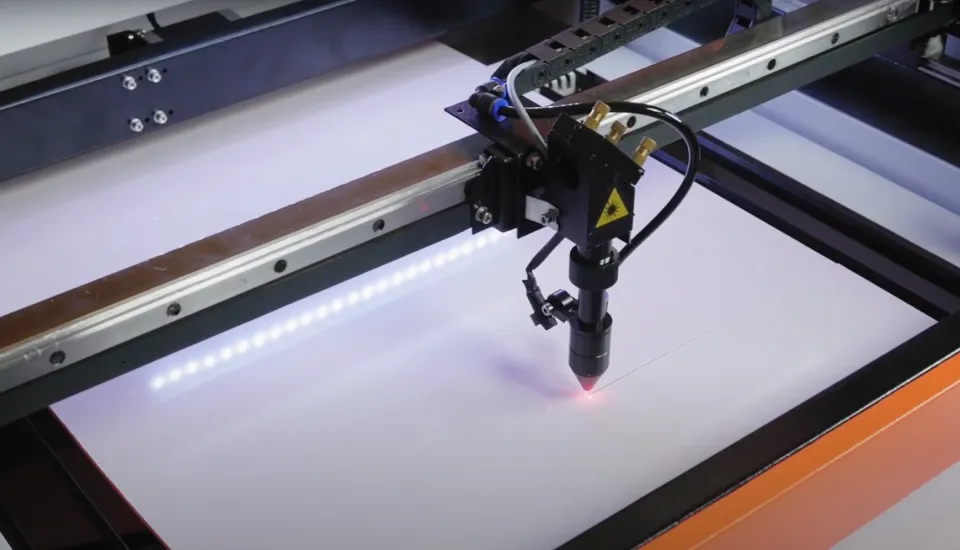

Laser machines with "flying optics"

Laser machines with flying optics have a system of mirrors that reflect the laser beam coming out of the emitter. These are three mirrors – one is stationary and located directly at the emitter, and the other two are fixed on different parts of the portal and move, or “fly”, together with it.

Engraving on machines of this type occurs due to the movement of the working head along the portal on the X axis with a shift of a given step along the Y axis. Thus, the machine burns out a specified image or inscription step by step. If you take a video of the machine and speed it up several times, you will see how the image appears from the bottom to the top (or from top to bottom, depending on the settings).

CO2 laser machines with flying optics are divided into engravers and cutters. This division is extremely conditional, because both can perform both functions – cutting and engraving, but each type of equipment still has its own specialization.

This specialization depends on a number of parameters:

- Lens focusing. Long-focus lenses have a slightly larger spot size, but are better suitable for cutting, since they have a large caustic zone - that is, they can cut through thicker materials. And short-focus lenses are designed for engraving, as they give out a smaller spot size and therefore can perform a finer engraving.

- Nozzle cross section. The nozzle of the laser head is an opening through which the laser beam exits and the blowing is also applied here. The truncated nozzle is designed for cutting – firstly, the enhanced blowing is a combustion catalyst, which helps the laser to cut through the material, and secondly, since cutting is carried out through, all combustion products are blown out together with the air flow, so there is no residues left on the material. And the expanded nozzle improves the quality of engraving, since the blowing occurs over an area, its intensity is lower, so the air flow does not affix the combustion products to the surface of the material.

- The size of the working field. CO2 laser machines with flying optics have different sizes of the working field – from 200x300 mm to 2000x3000. The larger the table, the less CO2 the machine is designed for engraving and more for cutting. Desktop machines with working field sizes 200x300, 500x300, 600x400 are considered to be engravers. Medium-format machines with a working field of 600x900, 1200x900 are designed for both cutting and engraving, and machines with a large working field, for example, 1600x1000 or 2000x3000 are considered cutters, although they are also capable of engraving. This is justified by the physics of the laser beam – the larger the working field, the stronger the divergence of the laser beam, which means the larger spot size, which does not have a very good effect on the result of engraving. In addition, it is structurally more difficult to maintain accuracy requirements on large working field sizes and avoid vibrations during operation.

For a CO2 laser machine with flying optics, the frame and the portal are especially important, since the engraving takes place at speeds up to 500 mm/s, the machine experiences strong inertial loads. Wattsan engineers have carried out extensive work to strengthen the body and portal of the machine and reduce vibrations in order to achieve good accuracy even on wide-format cutting machines.

You can learn more about CO2 laser cutting and engraving machines from our article. In addition to CO2 laser engravers with flying optics, there is also another type of equipment designed for engraving — laser markers, including fiber-optic machines for metal engraving.

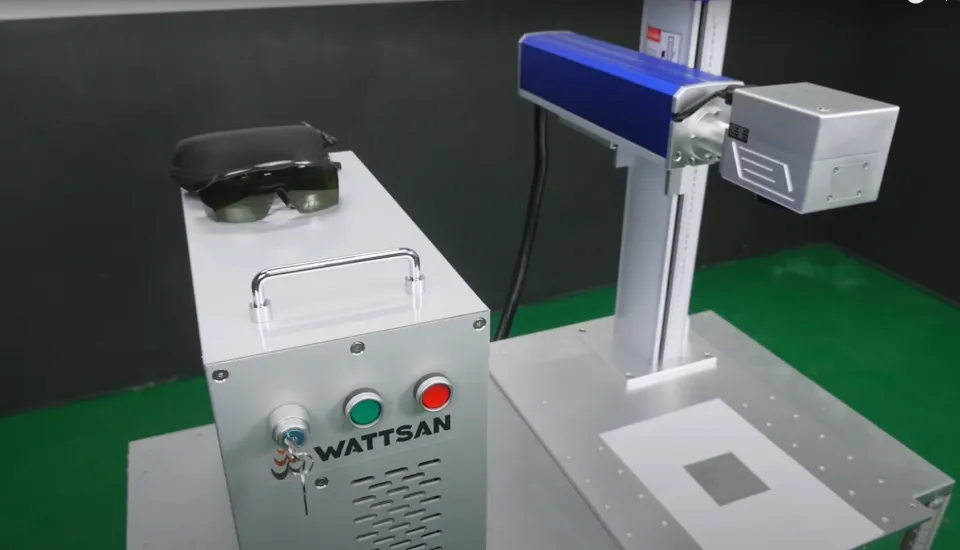

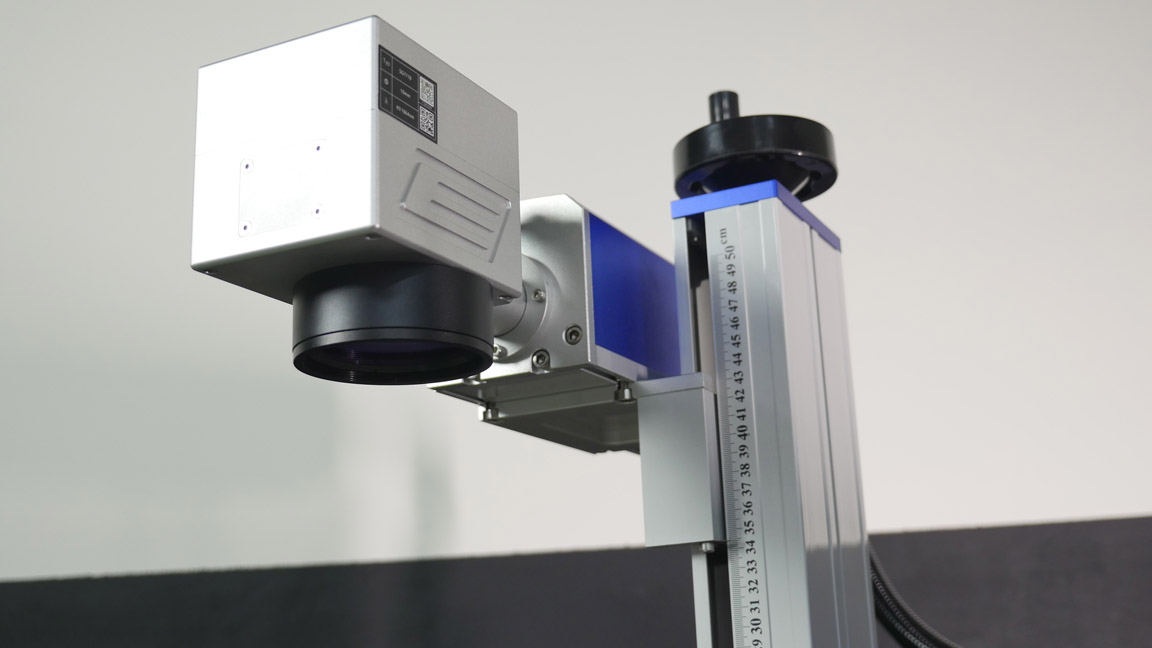

Laser markers on galvanometric scanners

In laser markers, laser beam positioning takes place in a two-axis galvanometric scanner Sino Galvo. The scanner is a small box containing two movable mirrors that reflect the laser beam along the X and Y axes. This allows the laser to be positioned at any point on the plane within the working field.

The laser marker is compact – it can be easily placed on a regular desktop, the movement of mirrors in the scanner is silent, the machine has no inertial forces during operation. For desktop machines with flying optics, a reinforced table is needed, since the mechanical movement of the working head during engraving will swing it.

Laser markers can be fiber-optic, that is, they work on metal, and they can be with a CO2 emitter, that is, designed for wood, plastics and other non-metals.

You can read more about laser markers in our article. And now we will discuss the general criteria for choosing a laser engraving machine.

How to choose a laser engraver - the main criteria

To avoid a mistake with the choice, it is necessary to take into account several main factors at once:

- Type of emitter. Decide what kind of material you will work with. If these are non-metals: plywood, MDF, wood, plastics, ceramics, stone, glass and mirror - you need a CO2 emitter. If metals are your priority, you need a fiber optic emitter.

- Emitter power. For laser markers, the power of 20-30 watts will be optimal for most tasks, for high-speed deep engraving or for engraving highly reflective metals, an emitter of 50 watts will be required. For CO2 laser engravers with flying optics, a CO2 emitter of 50 watts is needed, but if you also plan to combine engraving with cutting, it is better to pay attention to machines with a power of 80 watts or more.

- Service life of the emitter CO2 laser tubes for engravers serve from 2 to 8 months, depending on the power and manufacturer. When the laser tube fails, it needs to be replaced with a new one. Fiber-optic emitters serve for more than 11 years.

- Working field. Laser markers are limited to a maximum working area of 300x300 mm. CO2 laser engraving machines with flying optics have sizes from 200x300 to 2000x3000 mm., they can engrave both large products, for example, signs for shops, coffee shops, bars or pastry shops, and launch many small layouts for the entire working field at the same time.

- Working speed. Laser markers engrave at a speed of up to 7000 mm/s, laser machines with flying optics — up to 500 mm/s, but here you can engrave many identical products in the entire area of the working field at the same time, which speeds up the production process.

- Laser beam accuracy. Accuracy is important for application of complex, small, sometimes even microscopic images. The accuracy of laser markers reaches 0.001 mm, the accuracy of CO2 machines with flying optics is 0.03 mm.

- Software. Operation programs for markers and engravers are not particularly difficult, however, a person without experience can get lost and is unlikely to be able to master all the functionality of such programs on their own. Therefore, we recommend using the training that you can take at Virmer.

- Additional features. When choosing an engraver or a marker, it is worth considering many additional nuances: will a rotary device be used, do you need cutting or only engraving, perhaps you need color engraving of metals, is it profitable to use two-headed laser machines? And there are too many such nuances to tell about all in one article. To get a comprehensive consultation, please contact our managers, phone: +31208082045 or email us at info@virmer.com.

- Reliability and support of the supplier. Virmer offers you delivery, commissioning, training, warranty, support and service. We are ready to send our engineers to you anywhere to solve all your problems.

Conclusion

As you can see, choosing an engraving machine is not an easy task, which largely depends on your input data and the tasks that you face. If you need an online demonstration of the equipment discussed in this article, or additional advice, please call us: +31208082045 or email us at info@virmer.com.

FAQ

What is a laser engraving machine?

A laser engraving machine is a special device that operates using Numerical Control (CNC) and is capable of engraving with a laser beam the necessary graphic information (image or inscriptions) on various surfaces.

How much does a cnc laser engraver machine cost?

The cost of a laser engraver depends very much on the type of emitter, the size of the working field, as well as on additional functions and equipment. The price can range from 1000 to 10000 euros.

Which wood can be engraved with a cnc laser?

With the help of a CO2 laser, you can engrave any type of wood materials: solid wood, plywood, MDF and others.