Laser cutting of metal is the fastest, most convenient and profitable way to cut metal up to 40 mm thick. With the help of laser machines, metal housings for machinery and cars are produced, iron doors, steel shelves, facades for facing buildings are made, parts and elements of metal structures of both simple and complex shapes are cut.

In this article we will make it clear what are the advantages of laser machines for metal, we will tell you how to choose such a machine, what is the principle of its operation and what metals such equipment can cut.

Laser cutting of metal: why it is effective

Fiber laser machine for metal has the following advantages:

- Idle speed of Wattsan metal cutters, depending on the machine model, ranges from 80 to 120 m/min. The process speed with thin metals can reach up to 60 m/min. Such indicators guarantee record performance in comparison with other types of metal cutting.

- The efficiency of a fiber laser is >40%, a figure unattainable with any other method of metal cutting. This is achieved because fiber-optic emitters generate monochrome coherent radiation with minimal divergence and a stable radiation frequency. The wavelength is 1.064 microns and is optimal for interaction with metals.

- The material does not overheat due to the properties of the laser beam, especially when it comes to thin metal. Therefore, it is possible to cut even the most complex products with jewelry precision, without fear that the metal will deform.

- No scale is formed on the material face, so the metal does not require post-processing.

- Precision cutting of contours of any complexity is achieved due to the small diameter of the laser beam and the repositioning accuracy of 0.02 mm. The sheet material blanks can be positioned butt to each other, thus saving material.

- Numerical Control (CNC) minimizes the probability of rejects and guarantees one hundred percent repeatability of products.

- The service life of fiber emitters reaches 100,000 hours, which is more than 11 years.

- Laser metal machines require minimal maintenance, they are easy to integrate into the production process, including laser work, new personnel can be quickly trained.

Laser machine selection criteria

All selection parameters and accessories directly depend on the type and thickness of the material that you will cut, as well as on the desired cutting speed and idle movements of the machine. Each element of the machine design must be selected in accordance with the tasks to be solved and the loads received.

Emitter of Laser Metall Cutter

The thicker the material, the more powerful the emitter is needed. It is obvious that thinner metals can be cut at a higher speed with a more powerful emitter.

For metals with a high reflection coefficient, Virmer engineers recommend using special emitters with protection against back reflections. To date, IPG emitters, the world leader in the production of fiber-optic emitters, are equipped with a similar solution.

Fiber emitters of other brands, such as Raycus and MaxPhotonics, are also presented on the market.

To select the appropriate power of the laser emitter, contact the manager of the Virmer company: +31208082045, е-mail: info@virmer.com.

Laser head

The laser head focuses the laser beam on the material. The type of laser head depends on the power of the emitter. Laser heads with autofocus are used for fast penetration of thick materials.

One of the leading brands is the manufacturer of laser heads RayTools. Also, at the request of the client, the machine can be equipped with a WSX or Precitec laser head.

Frame and body of the laser metal cutter

The higher the idle speed of the machine, the tougher the body and frame

should be. If the load on these elements exceeds the one for which they are designed, then this is fraught not only with undesirable vibrations during operation, but also with a reduction in the service life of the machine.

Therefore, the frame and body of machine determine its designed speed. For example, Wattsan E-series machines are designed for idle movements at a speed of 80 m/min. and they have an all-welded frame with a cross-section thickness of 6-8 mm and Mitsubishi engines of 1 kW, and Wattsan S-series machines are designed for a travel speed of 120 m/min., the cross-section thickness of the all-welded frame of this series is 8-10 mm, and the engine power is already 1.5 kW.

Virmer recommends its customers to follow the principle of sufficiency — that is, to choose equipment strictly for the tasks and not to overpay for unnecessarily expensive components.

At the production stage, the frame of the laser cutting machine must be tempered in a special furnace with strict temperature control in order to relieve the stress of the metal. Without this procedure the frame will lose its geometry and the precision characteristics of the machine will be spoiled without the possibility of their restoration.

Portal of the laser metal cutter

Since the portal experiences constant loads during movement in operation, it must be robust, but at the same time light, since with a larger mass the inertial force will also be greater, which means it increases vibrations during operation. Therefore, the best solution is an aluminum portal structure — lightweight and durable.

Elements responsible for the movement of machine components

Only servomotors with planetary gearboxes can provide proper speed and acceleration to the laser metal cutter. Stepper motors are not suitable for this. Mitsubishi is one of the best manufacturers of servomotors for laser metal machines, and Shimpo is one of the best manufacturers of gearboxes.

All machine components move along rail guides and helical racks. The accuracy and repeatability of positioning depend on the parallelism and alignment of these elements.

To achieve this, top machine tool manufacturers, such as Wattsan, after annealing the bed, mill the platforms and drill mounting holes for the installation of rail guides and helical racks using high-precision robotic systems.

Pay attention to the brand: HIWIN has been producing reliable high-precision linear guides with high load capacity, low coefficient of friction and smooth running for more than 30 years. The helical rack Lean B2 is specially designed for serious loads.

Well-known brands of components give not only confidence in quality, but also affordable service around the world.

In addition to the brand of individual components of the laser metal cutter, it is important to pay attention to the fact that all of them must be designed for each other and for the planned loads. This is done by the development and testing department of the manufacturer of laser machines.

Top Laser Metal Cutters

The price of a laser metal cutter depends on the power of the emitter and a number of other parameters. To check the price of a laser metal cutter in a configuration suitable for your tasks, or to sign up for an online demonstration, contact the managers of Virmer: info@virmer.com ; WhatsApp +31633967402.

Wattsan 1325E Metal laser cutter

It is best suited for cutting metals 3-4 mm, equipped with an emitter with a power of 1 to 2 kW, develops a speed of 80 m/min. The size of the working field is 1300x2500 mm.

You can find detailed information about this model on our website

Wattsan 1530S

Designed for thicker metals of 3-12 mm, equipped with an emitter with a power of 1 to 6 kW, develops a speed of 120 m/min. The size of the working field is 1500x3000 mm.

You can find detailed information about this model on our website

Wattsan 1325 Tablechange

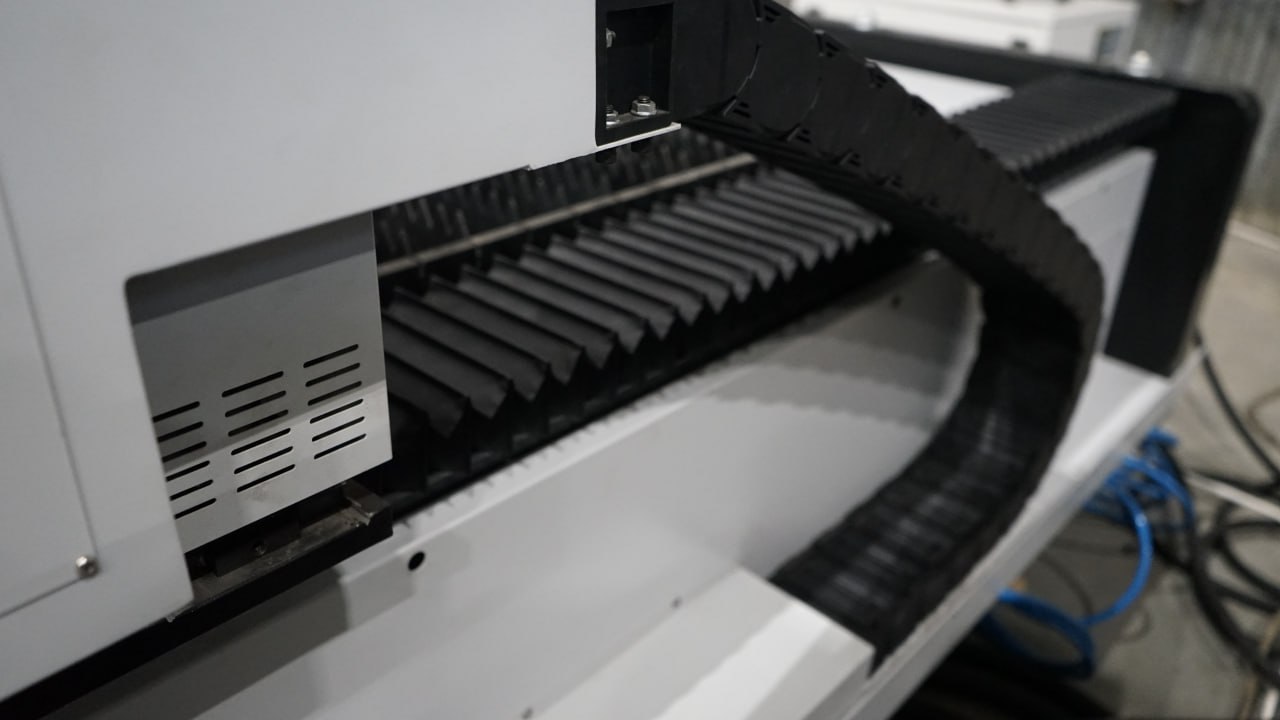

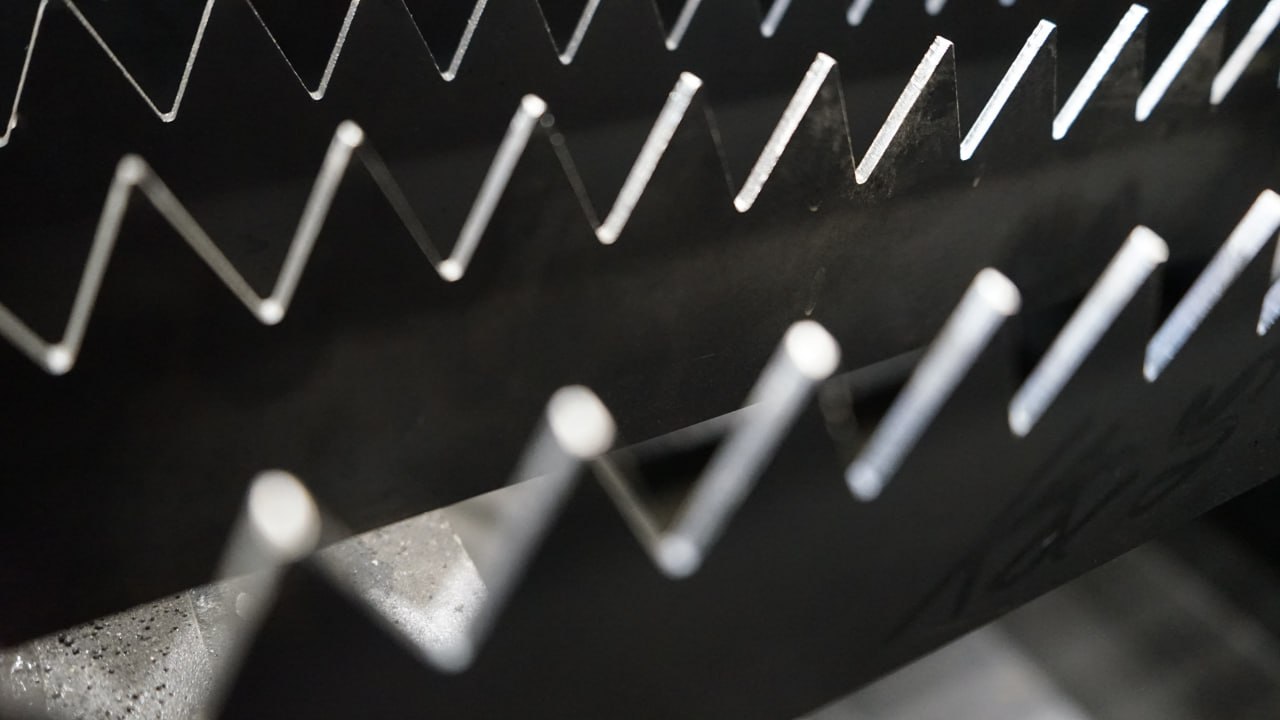

Tablechange is an additional function that can be installed on any Wattsan S-series laser metal cutter.

Tablechange is a system consisting of two interchangeable tables, thanks to which work is carried out continuously — while cutting is carried out on one table, the machine operator collects finished products on the other and lays a new sheet for the next operation.

Laser cutting machine for metal pipes and profiles Wattsan RD

This machine is designed specifically for cutting metal pipes and profiles, it performs cutting contours of any complexity: holes, incisions, grooves. In addition to pipes and profiles, Wattsan RD cuts an I-beam.

The power of the emitter depends on the thickness of the metal, the length of the processed pipes is up to 6000 mm. You can find detailed information about this model on our website

Wattsan 1530S Rotatory

If it is necessary to process both sheet material and pipes and profiles, then there is a Wattsan 1530 Rotatory for these tasks. The dimensions of the working field for sheet material are 1500x3000 mm, this machine will cut a circular pipe with a diameter of up to 220 mm and a rectangular pipe with a cross-section of up to 160 mm and a length from 3 to 9 meters.

You can find detailed information about this model on our website

Check the actual price of the model you are interested in with Virmer's managers: +31208082045, е-mail: info@virmer.com

See the full catalog of laser metal-cutting machines on our website

How laser metal cutting works

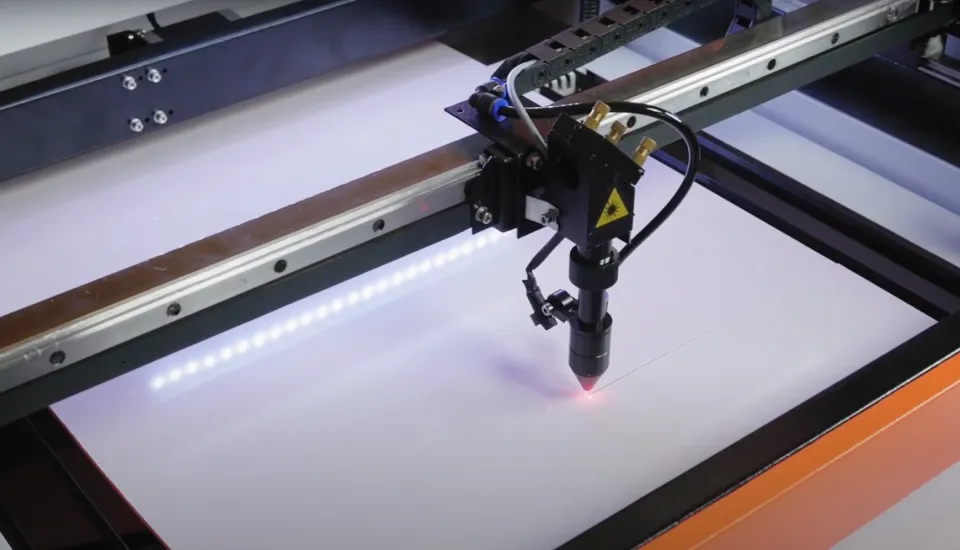

In the emitter, laser radiation is generated using pump diodes and a pump resonator, which is transmitted through an optical fiber laid in a cable channel to the laser head, where it focuses and falls on the processed material.

A focused laser beam heats up the metal to the melting point in a fraction of a second, and the gas supplied to the cutting point blows out the molten material.

Which metals are suitable

Almost any metals are suitable for cutting with a fiber-optic laser, including:

- carbon steel,

- galvanized steel,

- alloy stainless steel,

- copper,

- brass,

- aluminum,

- titan,

- other metals.

A specific gas must be used to cut each type of metal. For cutting carbon steel up to 3 mm thick, it is advisable to use air, this method implies the presence of a compressor. Thicker steel requires oxygen. If you need to cut aluminum, copper or stainless steel, nitrogen is used, and argon is used for cutting titanium.

For detailed advice on the choice of gas for cutting metals, please contact the managers of Virmer: +31208082045, е-mail: info@virmer.com.

Is it possible to cut metal with a CO2 laser

A distinctive feature of the CO2 laser is a completely different type of emitter — it is a flask filled with a mixture of gases, the main of which is just CO2.

Standard CO2 lasers are not suitable for cutting metal for a number of reasons:

- CO2 lasers have a different wavelength — 10.6 microns, it is more suitable for working with such types of materials as wood (plywood, MDF, wood, veneer, cardboard), polymers, leather, fur, textiles and is not suitable for working with metals;

- you need a special laser head with a sensor that recognizes metal so that you can focus correctly;

- a control system is needed that will control this working head;

- to cut through the metal, it is necessary to overcome the melting point, and this requires high power.

However, there is a CO2 laser machine that meets all of the above parameters.

Wattsan NC-1612

The power of the laser tube is 130-150 W, the size of the working field: 1600-1200 mm. This universal machine will cut metals up to 1.5 mm thick, as well as any other standard materials for a CO2 laser.

You can also find detailed information about this model on our website, check the current price with Virmer's managers: +31208082045, е-mail: info@virmer.com

Conclusion

Laser cutting of metal is the best and fastest way to get a product from sheet metal or from pipes of various cross-sections. However, such equipment costs serious money and if you need help in choosing a laser machine for metal, contact the managers of Virmer: info@virmer.com ; WhatsApp +31633967402.

FAQ

What kind of laser can cut metal?

A fiber-optic laser is best suited for cutting metal, but a specially equipped CO2 laser with a high-power laser tube may also be suitable for this purpose. However, it should be borne in mind that the thickness of the metal for cutting with a CO2 laser is limited to 1.5 mm, while a fiber-optic laser is capable of cutting up to 25 mm.

How much does an hour of laser cutting cost?

The cost of an hour of laser cutting depends not only on the power of the laser machine and the speed of its operation, but also on a number of other factors, such as: the professional skills of the machine operator, the cost of renting a production room, the cost and consumption of electricity, the cost of the material itself, the amount of scrap and downtime of the machine, and much more. In order to unambiguously answer the question about the cost of an hour of laser cutting, it is necessary to take into account all these parameters.

How laser metal cutting works

A focused laser beam is applied to the metal surface, as a result of which it melts, the molten material is blown out of the cutting zone with the help of an auxiliary gas.

How powerful should a laser be for cutting metal?

The power of the laser emitter depends on the thickness of the material being processed and the desired processing speed. For example, a 1 kW emitter will cut 1 mm thick stainless steel at a speed of 13 m/min, and a 3 kW emitter will cut the same material at a speed of about 35 m/min.

Here everything depends on the budget and the expediency of using the maximum possible capacity. Although it can be said that in today's competitive realities it does not make sense to buy a laser machine with a power of less than 1 kW.