Laser wood engravers most often refer to a laser wood machine with carbon dioxide, i.e. CO2 laser source. This is exactly the kind of a laser engraving machine we will be talking about in this article.

It is noteworthy that this laser engraving machine for wood can process not only plywood, MDF, chipboard, and other wood-based materials, but also the following materials:

- Plastics (acrylic, PET, ABS, polyethylene, polypropylene, polystyrene, and others);

- Rubber;

- Fabric;

- Leather and faux leather;

- Stone;

- Ceramics;

- Glass and mirror.

Advantages of a laser engraving machine for plywood and wood

- Production cost of goods. The materials for working on a laser engraver for wood cost considerably less than the products that can be made from these materials. Therefore, the laser engraving business has a high profit margin.

- Operation speed. The travel speed of the CO2 engraver laser head is up 500 mm/s, and for a CO2 marker, it can be up to 5000 mm/s. Thanks to this, the engraving of one image can take less than 1 second. Deep engraving of large images can take from several minutes to tens of minutes depending on the size.

- Precision and detail. The positioning accuracy of a good laser wood engraving machine is at least 0.03 mm. This allows for manufacturing highly detailed products.

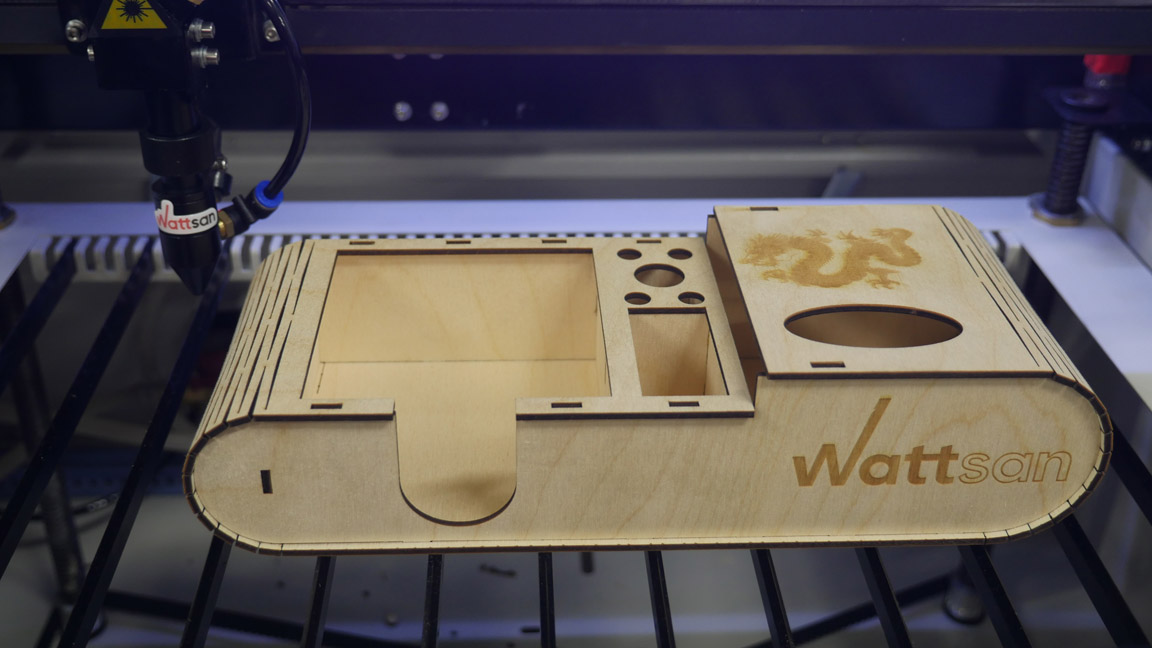

Wattsan laser wood engravers ensure a resolution of 2500 DPI. This is achieved by three-phase motors and belt drives that split the motors' pitch and relieve them of the load during operation.

- Simple and intuitive operation. Laser engravers for wood work on a CNC (numerical control) basis; all laser movements follow a set programme. All you need to do is prepare an image in a vector editor (you can use pre-made images), adjust the speed and power, and start the process. It takes 1-2 hours to learn the basics of using a laser wood engraving machine.

- High quality and repeatability. Thanks to CNC (numerical control), laser engraving machines ensure consistently high quality products with minimum possibility of rejects. A properly configured laser wood engraver produces a 100% repeatable product.

- Working with a variety of materials. A laser wood engraving machine works not only with plywood and wood but also with many other materials. This expands the range of possible products. For example, you can engrave on leather, plastic, glass or stone, as well as combinations of these materials.

What products can be made on a laser engraving machine for wood?

Every day we come across products made on a laser machine. A lot of products are made of plywood.

The sign in the bakery, the napkin holders in the café, the wallet and phone case, the magnet on the fridge all are made with a laser wood engraving machine.

A laser engraving machine works with both vector and bitmap images and is capable of applying photographic images on plywood, wood, MDF, and other materials.

Laser engraving machines for wood have the following scope of application:

- Advertising and information products. POS materials, logos, nameplates, signs, ticket numbers.

- Wooden souvenirs. Magnets, key chains, postcards, and other souvenirs are made with a wood laser engraver. The texture of the material is suitable for applying drawings, inscriptions, and logos.

- Children's toys, puzzles, and jigsaws.

- Personalized gifts. Wooden portraits, wall panels or paintings, as well as personalized engraved items.

- Engraved phone cases. Both wooden and leather or plastic ones. Engraving makes the accessory unique; it is possible to have it engraved to the customer's specifications.

- Engraving on some other materials. Engraving leather goods, making monuments, seals and stamps, decorating glass and mirrors, and more.

Operation principle of laser engraving machine for wood

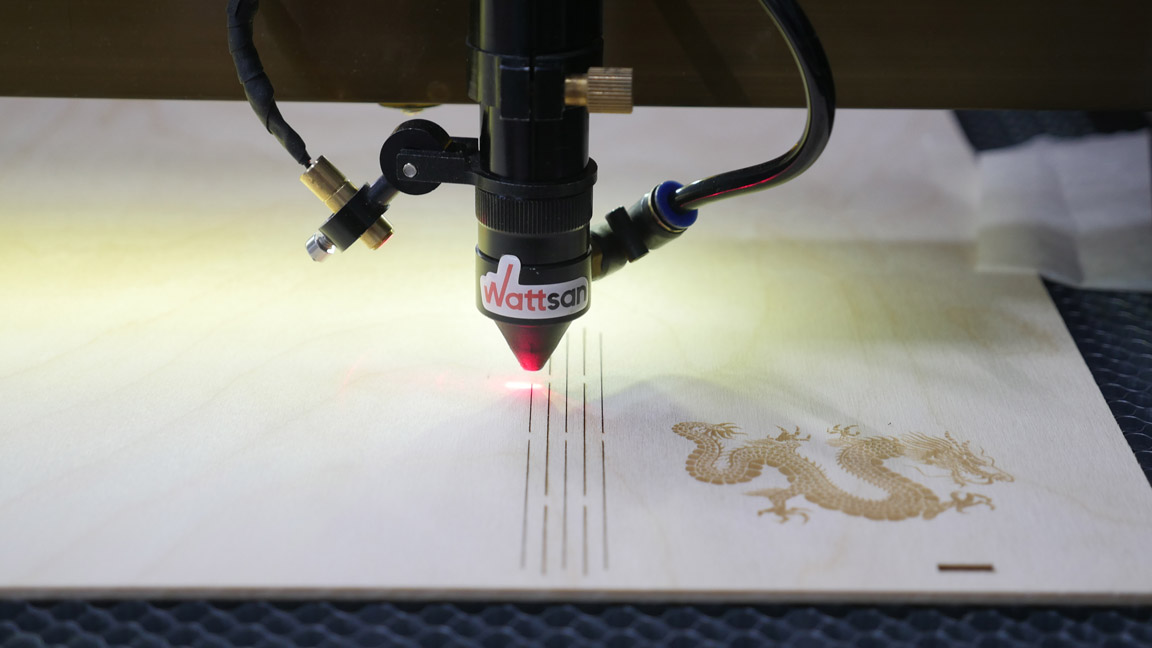

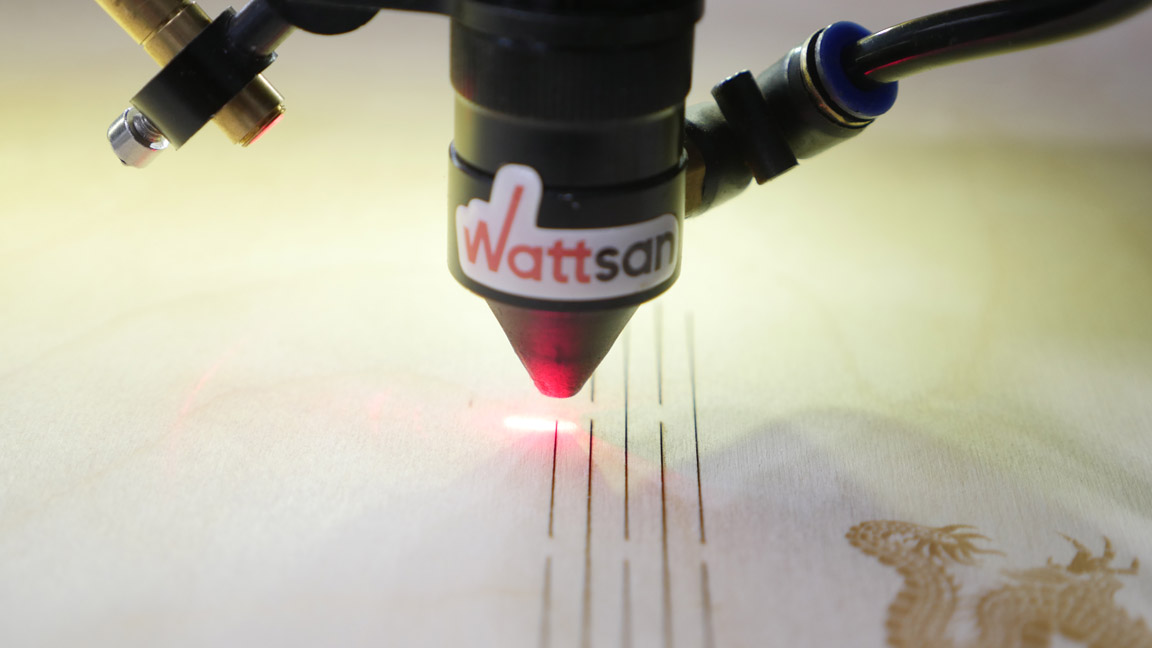

Laser wood engravers apply images and inscription on the material surface by means of thermal action of a laser. The impact force can be adjusted in order to obtain the desired depth of an image and its colour, ranging from light to almost black.

There are two main types of CO2 equipment for wood engraving, which differ in the way the laser beam is transported from the emitter to the material. These are laser engravers for wood with flying optics and laser markers with a galvanometric scanner.

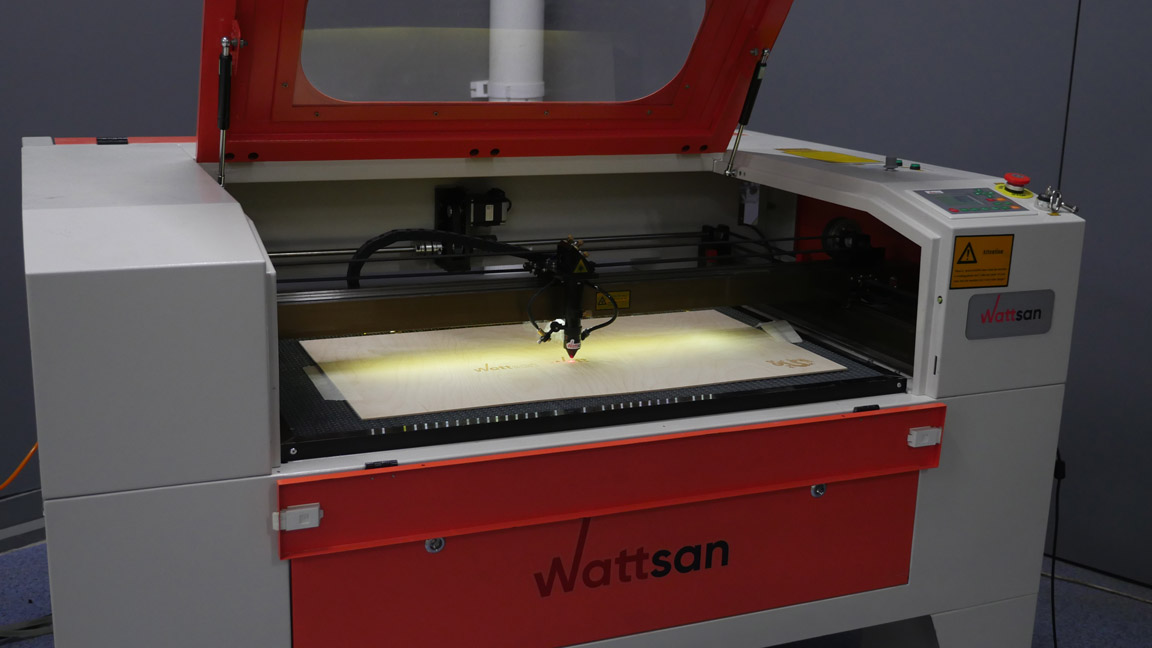

Laser engraving machine for wood with flying optics

With these laser wood engraving machines, the laser beam is directed to the point of processing through a system of mirrors, which are fixed on different nodes of the machine. The first mirror is fixed on the housing right next to the emitter, the second one is on the movable gantry, and the third one is on the working head.

Engraving occurs when the controller sends signals to the laser wood engraving machine where to move the gantry and the working head, as well as at what time period and at what power to apply laser emission. The laser head moves left and right along the gantry in the X-axis and moves stepwise up and down in the Y-axis.

The maximum speed for this type of engraving is up to 500 mm/s.

The power of these machines varies from 40 W to 180 W.

The working area size is 200х300 mm, 500х300 mm, 600х400 mm, 600х900 mm, 1200х900 mm, 1600х1000 mm or 2000х3000 mm.

Unlike the markers, laser engraving machines with flying optics are capable of both engraving and cutting materials.

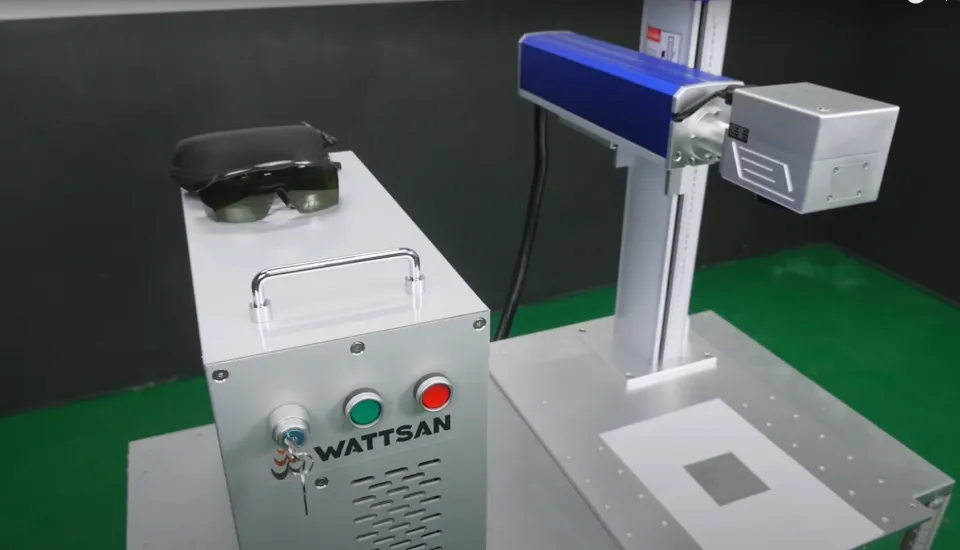

CO2 laser markers with a galvanometric scanner

Markers direct the laser beam by means of small but very fast moving mirrors, which are located inside a galvanometric scanner.

With this design, the operation speed of a CO2 marker is up to 5000 mm/s, which is 10 times the maximum travel speed of the laser head of a laser machine with flying optics.

The speed is up to 5000 mm/s.

The power of laser markers is from 30 W to 50W

Working area sizes: 50х50 mm, 75х75 mm, 110х110 mm, 200х200 mm, 300х300 mm, depending on the lens installed.

How to choose a laser engraving machine for wood

First, you have to decide whether you need engraving or both, engraving and cutting. If only engraving, pay attention to CO2 laser markers, for example, the Wattsan CO2 LT.

Pros:

- Operation speed up to 5000 mm;

- Accuracy 0,01 mm;

- A laser tube service life up to 10000 hours;

- A compact desktop laser engraving machine for wood;

- EzCad software that is easy to learn.

Cons:

- Maximum working area size of 300x300 mm;

- Relatively high cost. For about the same price you can get a laser wood engraver with a 600x900mm working area.

Please contact Virmer managers for the current price: +31208082045, info@virmer.com.

Read more about laser marking machines in our article.

If you need a laser engraver for wood and plywood to engrave and cut, then you definitely need a machine with flying optics. Here is the list of things you should pay attention to when choosing such equipment.

- Working area size of a laser wood engraver;

- CO2 laser emitter power of a laser wood engraver;

- Laser wood engraving machine housing;

- Laser wood engraving machine gantry;

- Lens focal distance;

- Nozzle diameter;

- Performance and service life of a laser wood engraving machine;

- Supplier reliability and support.

Let us now look at each point in more detail.

Working area size of a laser wood engraver

The size of the working area of a laser wood engraving machine affects the productivity of the machine, the maximum engraving size, the pre-cutting of the material, and the possibility of lowering the worktable.

Your production volume and capacity of your laser wood engraving machine

Before everything else, it is important what you get your laser engraving machine for. If it is a hobby, the Wattsan 0203 micro may be enough for you. It is a compact desktop machine with a 200x300 mm working area and a 40 W laser tube. The machine engraves at 400 mm/s and can cut plywood up to 4 mm. It is quite suitable for piecework, decoration, marquetry, quilling, and souvenir production. At 1369 €, this laser engraver for wood is a perfect tool for your hobby and helps you to explore the worlds of laser wood engraving machines.

If you need more than a hobby laser engraving machine for wood, look for machines with a larger working area.

Depending of the size of the working area, there are three types of laser engravers for wood:

- Tabletop models: 200х300 mm, 500х300 mm, 600х400 mm;

- Medium-format models: 600х900 mm, 1200х900 mm;

- Large-format models: 1600х1000 mm, 2000х3000 mm.

Tabletop laser wood engraving machines the Wattsan 0503 and the Wattsan 6040 have a working area of 500х300 mm and 600х400 and are suitabeld for medium to small production volumes.

Also, these laser engravers are used in manufacturies and joiner's workshops where laser engraving is not the main activity. These plywood and wood laser engravers are then used on an as-needed basis. However, it is worth noting that they are designed for 24/7 operation.

For medium to large production facilities, laser wood engraving machines are available in 600x900 mm and 1200x900 mm working area sizes, for example, the Wattsan 6090 and the Wattsan 1290.

Laser engraving machines for wood with a working area of 1600x1000 mm and 2000x3000 mm are considered large-format cutters, but they also engrave wood and other materials.

If you need to make the same products of medium or small sizes, the larger the working area size of the laser wood engraving machine, the more units you can produce in a single run of the machine. This saves time, both in the process of the work itself and in the changing of the sheet material. Keep in mind, however, that the larger the working area of a laser wood engraving machine, the more difficult it is to set up. Also with smaller dimensions, laser wood engravers retain their engraving accuracy better.

Consider the growth potential of your business when choosing a laser wood engraver. It may be better to buy a more productive laser wood engraving machine straight away if you are confident in your business plan.

Maximum size of engraving

Hypothetically, we can say that the maximum engraving size is limited by the size of the working area. Hypothetically it is because, with a cut-through table, you can calculate everything, contrive, install material retainers and special marks that will allow you to engrave in two or more passes if your material does not fit all the way into the working area. But this method is so unreliable that it is rarely used in commercial laser wood engraving. That is why we say that the maximum engraving size is limited to the size of the worktable.

Large-format laser wood engravers engrave signs, top boards, furniture parts, and other products.

Pre-cutting of material

Most laser wood engravers require the pre-cutting of standard sheet material otherwise they do not fit on the working area.

For example, if you work with 1200x2400 mm sheets of plywood, then without pre-cutting, you can only work on the Wattsan 2030 Flat Bed laser wood engraving machine, as its working area size is 2000x3000 mm. This large format laser engraver for plywood and wood is perfect for creating large engravings as well as for cutting materials.

Please check the current price with your Virmer account manager: +31208082045, info@virmer.com.

To pre-cut material, you can also use the Wattsan 1610. Its worktable’s width is 1600 mm, which is larger than the width of a sheet of plywood. Since the machine has a through-table, material of any length can be pulled through it as long as it fits the width.

1200х2400 mm plywood sheets can also be cut on the Wattsan 1290 LT. To work on the machines with a smaller worktable, you need to pre-cut material, which requires additional space in the workshop.

The Wattsan 1610 LT with a lifting table costs around 8 348 €, and the model with a static table is around 7 926€. For the relevant price, please contact Virmer managers: +31208082045, info@virmer.com.

Table lowering option

The table lowering function determines whether you can engrave voluminous and thick materials and workpieces, as well as whether you will be able to install a rotary device for working with cylindrical objects, such as glasses.

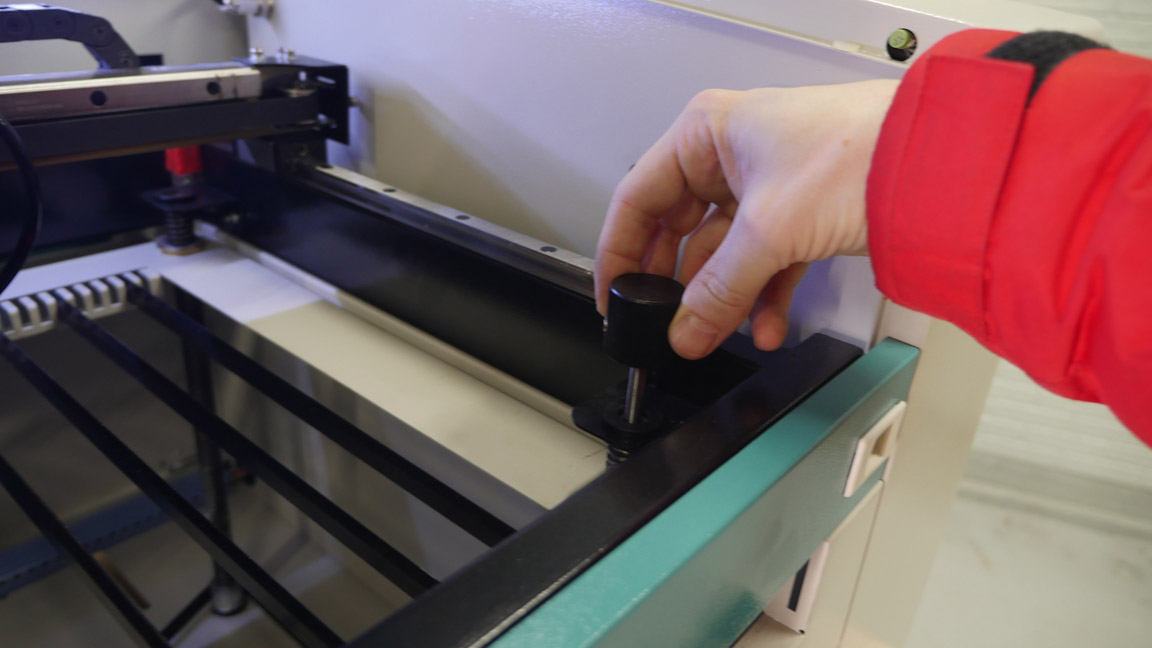

Laser wood engravers can have a manual table lowering mechanism, such as laser wood engraving machines the Wattsan 0503 and the Wattsan 6040 , and an automatic table lowering mechanism as on the Wattsan 6090 LT, the Wattsan 1290 LT and the Wattsan 1610 LT. LT stands for Lifting Table and has a lowering depth of 160 mm.

Wattsan machines marked ST (Static Table) have a fixed table, can work with a maximum material thickness of 40 mm, and do not allow the use of a rotary device.

Power of a laser engraving machine for wood

Laser wood engravers are fitted with a 40W to 130W emitter. If required, it is possible to install a more powerful laser tube of 150 W or even 170 W, but these laser sources are generally used for industrial cutting of material and not for engraving.

If the power of the laser tube is indicated with a dash, e.g. "100-120W", the first digit indicates the regular power and the second digit the maximum power. At maximum power the laser tube is not capable of working for a long time and is rarely used for engraving so the first figure is more important, the regular power.

What power a laser wood engraving machine requires

For engraving, a laser tube power of 40 to 100-120 W is quite enough, depending on the machine’s model and your production needs. If engraving and cutting materials up to 5 mm thick is your main task, the Wattsan 0503 desktop laser engraving machine for wood is the right choice.

Wattsan 0503 specifications:

Working area size: 500х300 mm;

Power: 60 W;

Operation speed: up 500 mm/s;

Accuracy: 0,03 mm, which enables this machine to engrave a 1x1 mm letter.

The Wattsan 0503 is designed specifically for 24/7 continuous engraving; despite its small size, the thickness of the machine body and gantry and guide rails are the same as on the advanced models. The power of 50 W in combination with a short focus lens makes it possible to achieve the minimum spot size of the laser beam, which is very important when engraving miniature images or inscriptions.

The model costs about 3 265 €, please check the current price with your Virmer account manager: +31208082045, info@virmer.com.

Pay attention to the service life of the laser tube. It depends on power, manufacturer, and service conditions and may vary from 1500 to 10000 hours.

Laser machines with a larger working area size are equipped with a more powerful laser tube. There are two reasons for this: firstly, these machines are most often used for both, engraving and cutting, and secondly, the laser beam, passing through air, is somewhat scattered and loses some of its power therefore in order for the machine to ensure a good result even in the far corners of the worktable, a more powerful laser tube is required.

For example, the Wattsan 6090 LT is equipped with a Reci W2 laser tube with 90-100 W of power.

Wattsan 6090LT specifications:

Working area size: 600х900 mm;

Power: 90-100 W;

Operation speed: up 500 mm/s;

Accuracy: 0,03 mm.

Thanks to a more powerful laser tube, this machine can be used for both cutting and engraving. The Wattsan 6090 LT cuts plywood up to 10 mm with a good result and, at maximum power, can cut even 20 mm, but very slowly and with heavy charring of the material end.

To minimize vibration and increase resistance to inertia during engraving, the machine is equipped with a welded frame made of shaped pipes.

The price of this model is around 5213 €; for the relevant price, please contact Virmer managers: +31208082045, info@virmer.com.

Virmer recommends that customers do not use the laser tube at more than 80% power to extend its service life.

Effect of power on speed and quality of results

On the one hand, the more powerful the laser tube, the faster the engraving and cutting will be. On the other hand, with more than 100W, it is more difficult to achieve accurate exposure on the material.

On solid wood, for example, ablation - evaporation of the top layer of material - can be done at fine settings to bring out the natural pattern of tree rings, which looks noble and gives the wood an aesthetic appearance.

The quality of the result is also affected by the size of the laser spot. The higher the power, the larger the diameter of the laser beam. This parameter determines how detailed an image you can obtain.

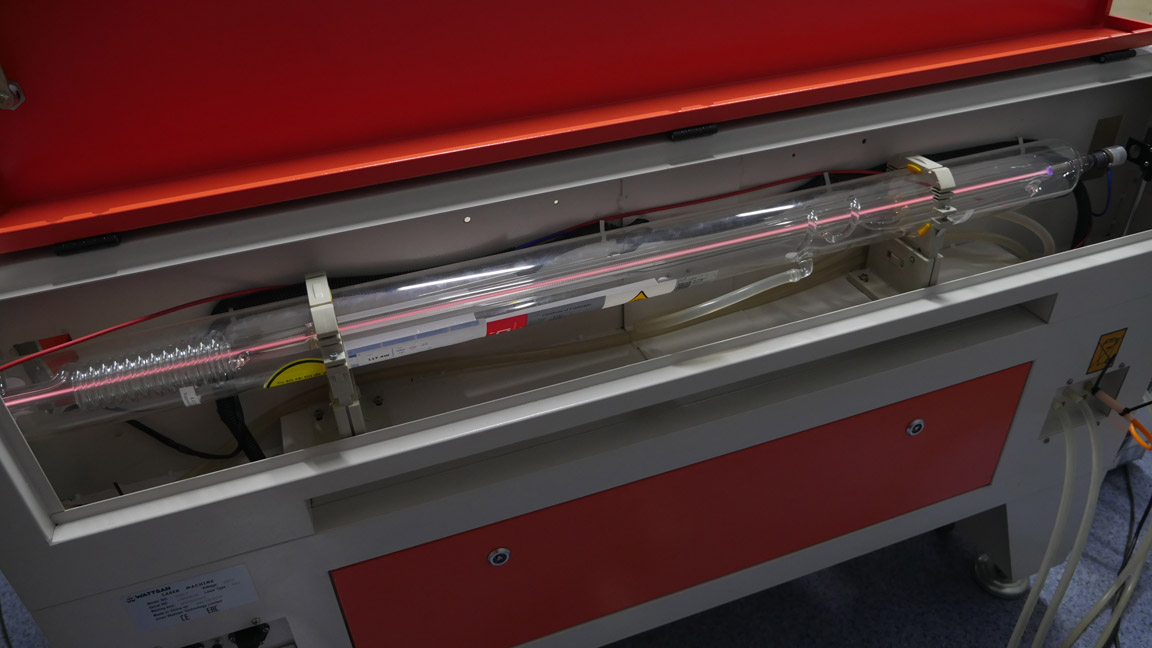

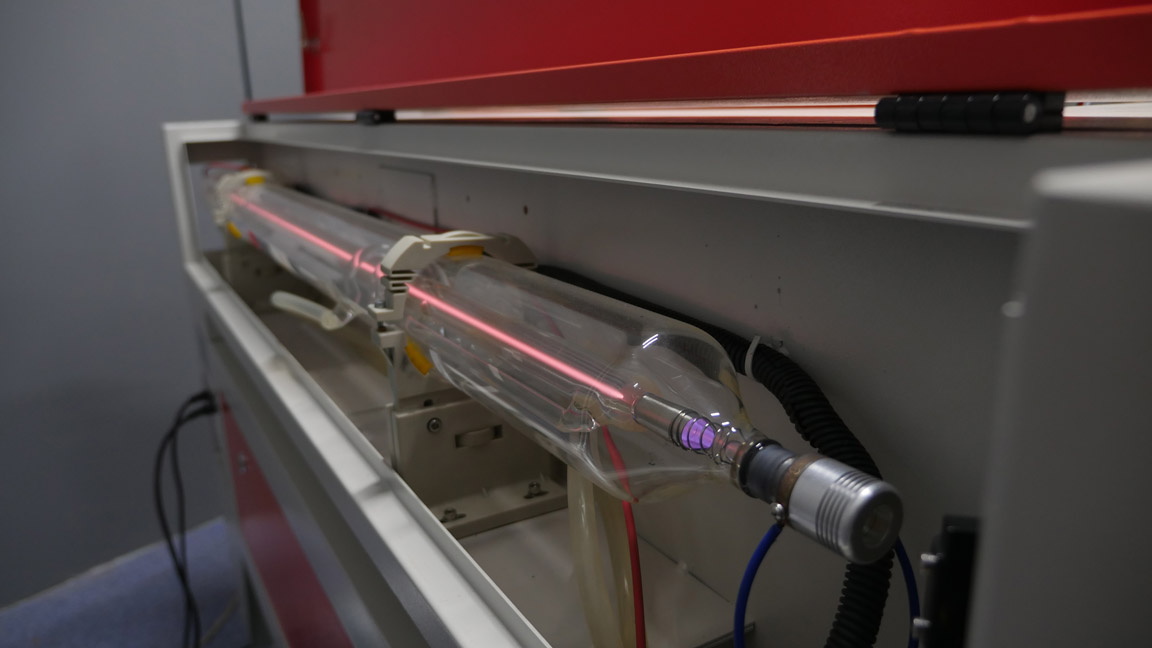

Cooling the emitter of a laser engraving machine for wood

Don't forget the cooling of the laser tube. The best solution is to buy a chiller, as it has a closed circuit and active cooling. The current temperature is shown on the display, and in case of a malfunction, the chiller will stop machine operation and emit an attention-grabbing signal.

Laser tube mounting

Also, when selecting a laser wood engraving machine, pay attention to the laser tube mountings. Some manufacturers skimp on this point. A good mount should have adjusting ring bolts for easy adjustment.

Machine body

Pay attention to the thickness of the machine body and the provision of a reinforcement frame. The minimum thickness of the body of a laser wood engraver must be 2 mm. Wattsan laser wood engravers have a housing thickness of 2.9 mm, and all models with a working area size of 600x900 mm and larger have a frame. The frame and the thickness of the housing have a direct influence on the stability of the housing and vibration damping during engraving.

Gantry

When engraving, the main inertial loads fall on the portal and the working head. It is along the gantry that the working head moves at a maximum speed of 500 mm/s.

The gantry must be sturdy to maintain accuracy throughout the service life of the machine.

Gantries on Wattsan wood laser engraving machines are made of 7 mm thick (on the corners) aluminium profile. As practice shows, such gantries do not lose their geometry even after 10 years of service.

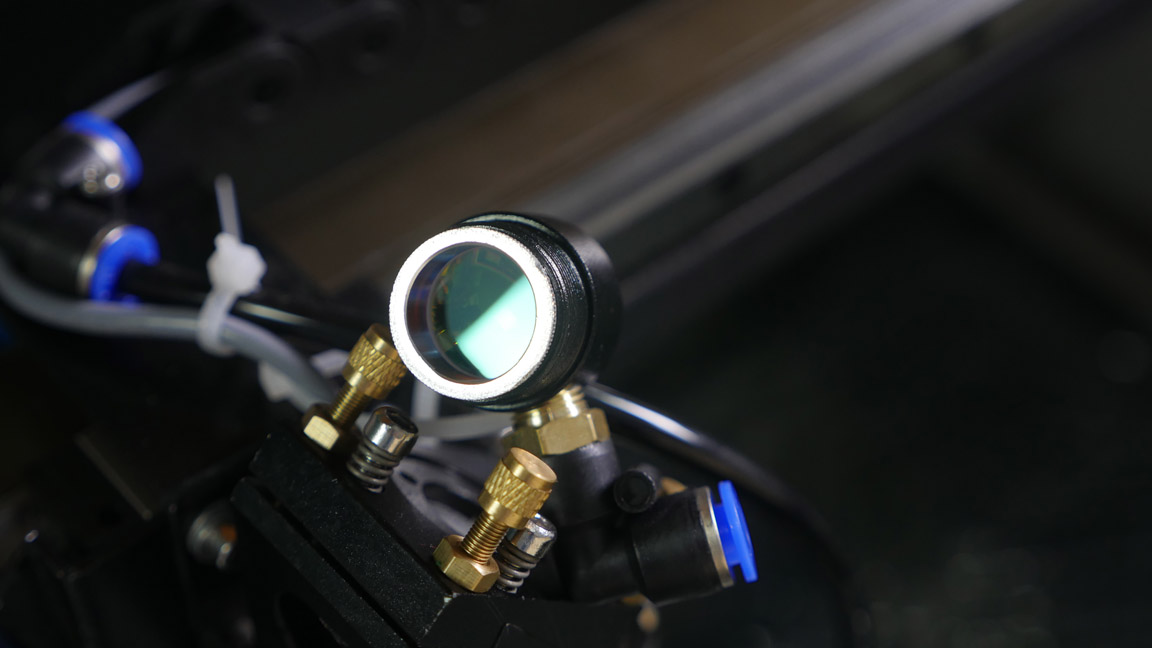

Lens focal length

Particularly important for engraving is the choice of focal length of the optics. The focal length is designated as F.

Three types of lenses:

- Short focus, F is less than 40 mm;

- Medium focus, F is from 40 to 75 mm;

- Long focus, F is more than 75 mm.

A short focus lens focuses the laser beam to a smaller spot than a medium or long focus lens. This allows for more detailed engraving.

The long focus lens is designed for cutting thicker materials as it has a larger caustic zone, i.e. the depth of focus. This allows you to cut thicker materials but gives a larger diameter laser beam.

Long focus lenses are poorly suited for engraving.

If engraving is your only task, choose a short focus lens. If you need both cutting and engraving, a medium focus lens will be the best option, as it is versatile.

For example, the Wattsan 6090 LT wood laser engraving machine has a medium focus lens, as it is designed for both engraving and cutting. The Wattsan 0503 and Wattsan 6040 laser engravers on wood have a short focal lens by default since these models are mainly intended for engraving. In addition, these machines have an extended nozzle diameter specifically for engraving.

You can always buy the right lens or machine for your needs from Virmer, contact our managers: +31208082045, info@virmer.com.

Laser head nozzle diameter

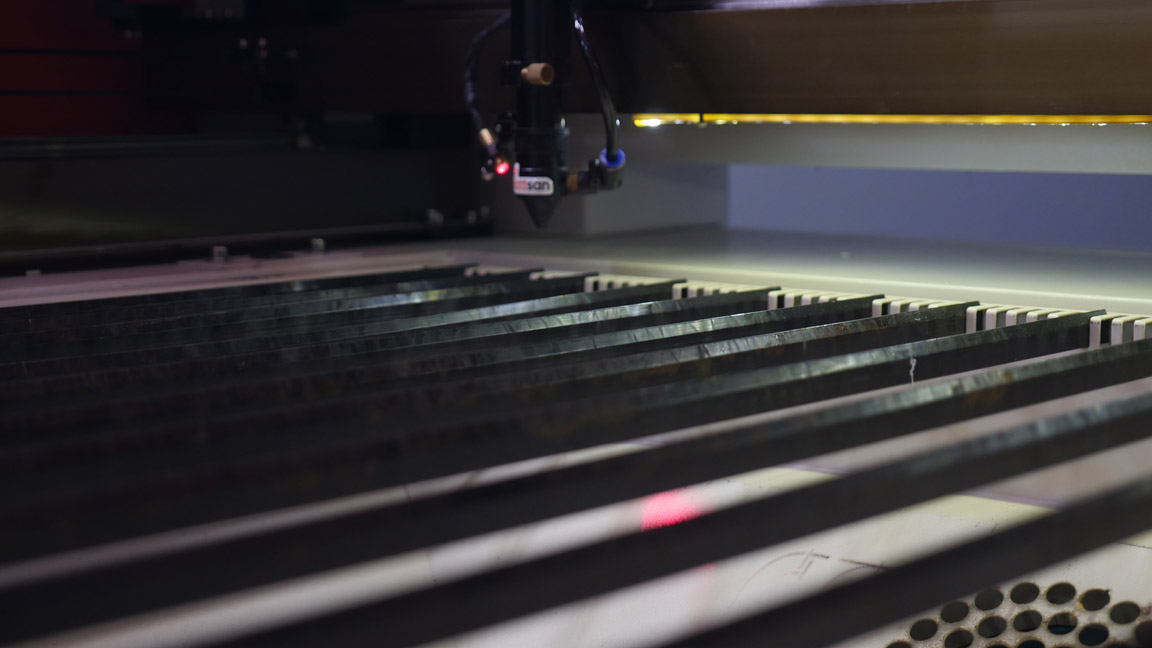

The nozzle is the hole in the laser head through which the laser beam exits onto the material and a stream of air is fed into the cutting zone. Air has two functions when cutting: it contributes to better cutting through the material, as it is a combustion catalyst, and blows the soot and carbonization products out of the cutting zone so that wood materials do not burn.

The more powerful the airflow, the better for cutting, but not for engraving.

If you use the same strong airflow when engraving, the fouling will stick to the material surface because of a powerful stream.

Therefore, a truncated nozzle is used for cutting to increase the directional airflow and an enlarged nozzle for engraving to reduce the airflow so that the engraving is cleaner.

Performance and service life of a laser wood engraving machine

In addition to the quality of the machine bed, frame, sturdiness, and power of the laser tube, there are also several important factors that affect performance and service life of the equipment:

- Number of working heads;

- Engines, their equipment and correct location;

- Guide rails and bearings;

- Belts.

Now let us talk about each point in more detail.

Number of working heads

If you want to make your work twice as fast, consider laser wood engravers with two working heads, for example the Wattsan 1290 ST Duos. The robust, reinforced gantry features two working heads that synchronously perform their task on each half of the working area.

There is also the Wattsan 1610 Duos LT, a model of a laser engraving machine for wood with two heads with a working area size of 1600x1000 mm.

The Wattsan 1290 Duos ST with a static table costs around 6043 €, a model with the same working area with a lifting table (LT) costs about 6580 €. Check the relevant price with Virmer managers: +31208082045, info@virmer.com.

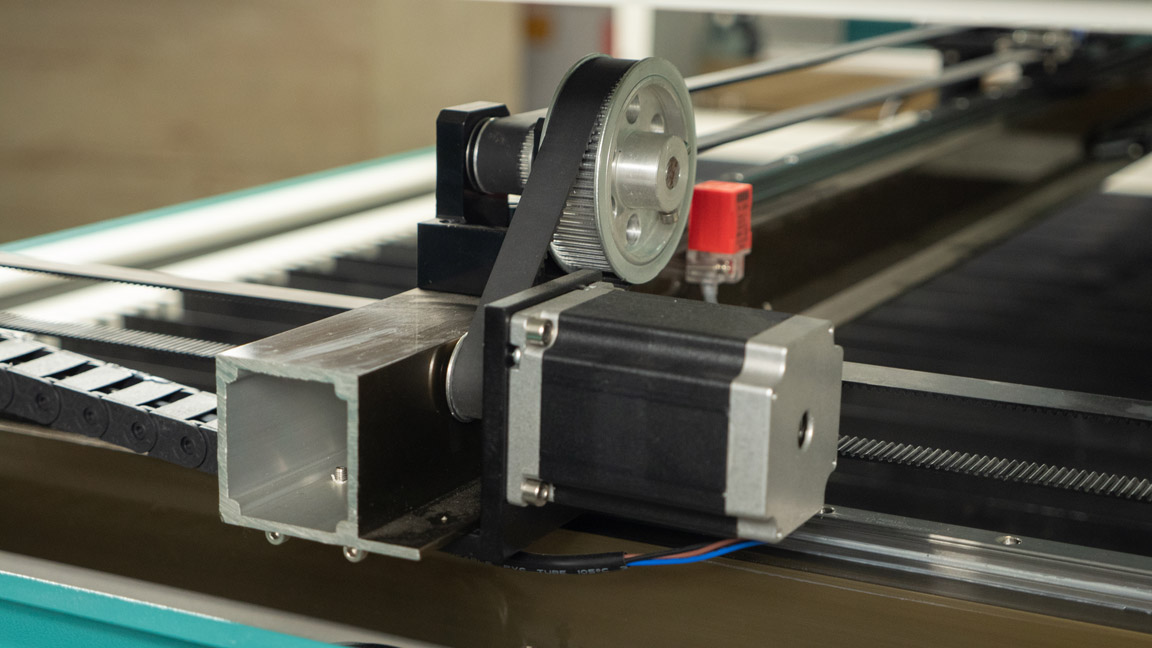

Engines

When selecting a laser wood engraving machine, pay attention to the engines, in particular to the following important points:

- Two-phase or three-phase stepper engine. Modern models of laser wood engravers feature three-phase motors. They have a greater pitch accuracy, which increases the accuracy of the machine. In addition, three-phase motors provide faster accelerating and braking, which is very important during engraving: this helps to reduce the exit from the engraving zone at the moment of changing the direction of motion.

- Provision of gearboxes. The gearbox splits the step of the engine; this allows you to achieve an engraving resolution of 2500 dpi. Also, the gearbox allows for high acceleration while relieving the load on the stepper motor, thus extending its service life.

- Y-axis positioning of the motor. The correct position of the motor in the Y axis is only in the middle of the rotary shaft. If the motor is positioned to the left or right, the shaft will be loaded unevenly and over time this will have a negative effect on the accuracy of the machine.

Guide rails of a laser engraving machine for wood

The moving parts of the laser engraver for wood - the gantry and the laser head - move along the guide rails.

The guide rails must ensure that the machine maintains its accuracy at high speeds under all loads.

There are three main types of guide rails for laser engraving machines for wood:

- Roller rails. As a low-cost option, they can only be used on machines with a working area of no more than 200 x 300 mm. On larger models, they will be very unreliable, showing poor accuracy and quickly developing backlash.

- Polished shafts and cylindrical rails. Most often used in 3D printers or budget wood laser engravers in order to save costs. Many cylindrical rails have no support along their length, which is unacceptable with medium or wide worktable formats. Polished shafts and cylindrical rails are quite sensitive to the dust and resins generated by laser woodworking.

- Profile guide rails. They guarantee high precision, are designed for high loads, and are wear-resistant. No backlash at all.

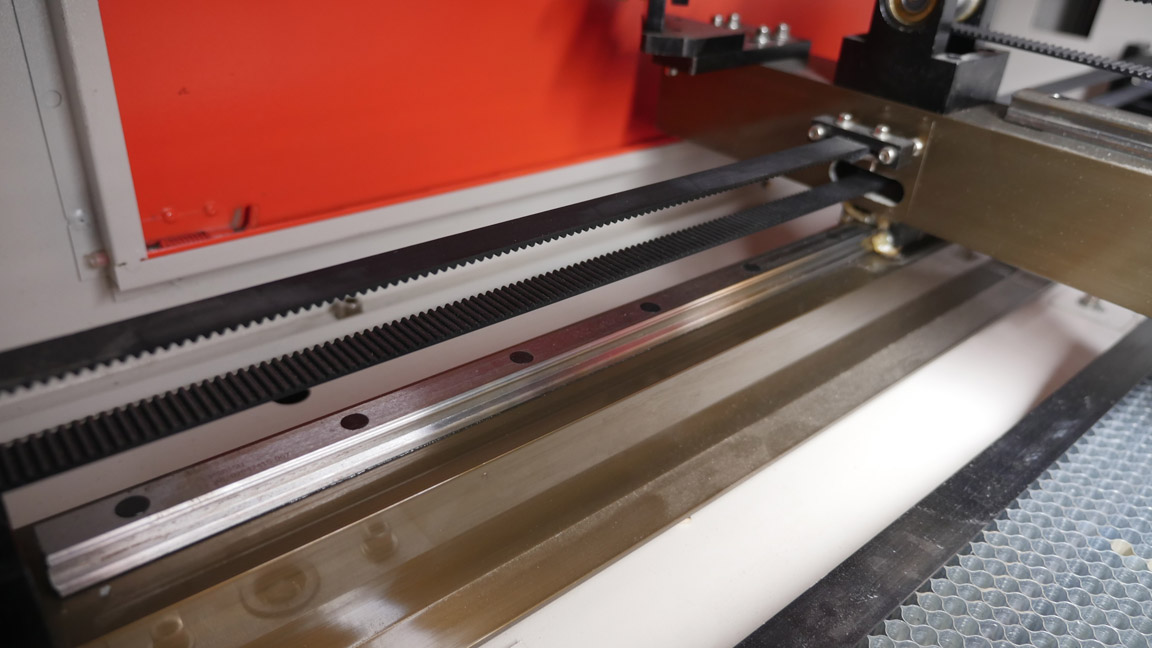

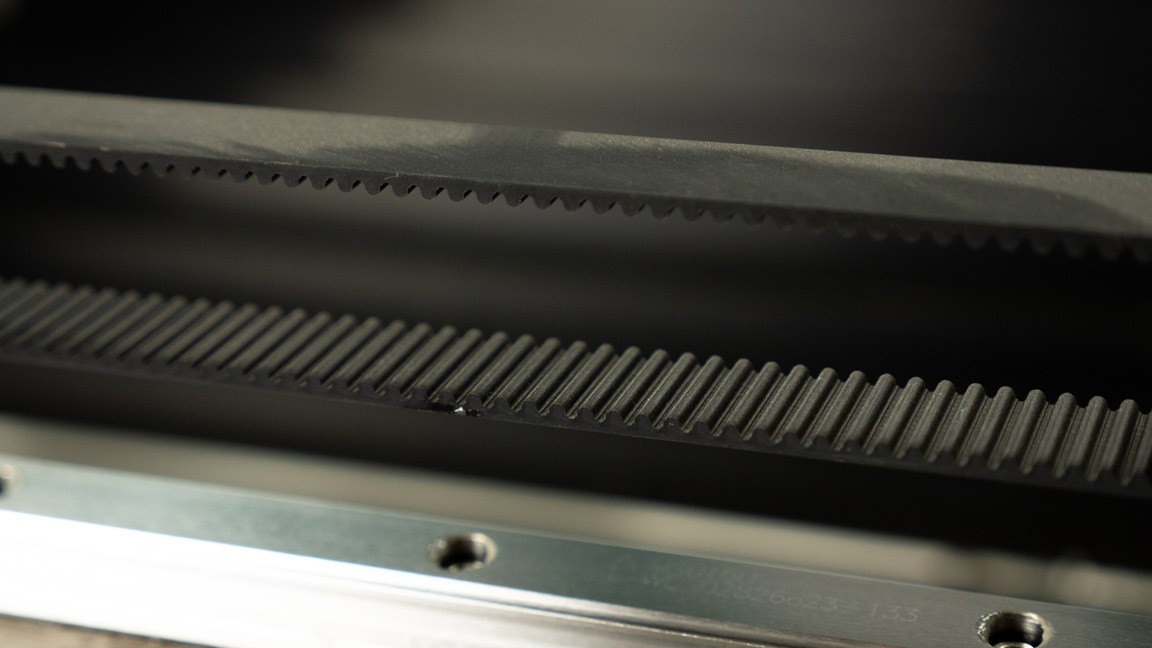

Belts

Belts are often seen as consumables on laser wood engravers because they often break under stress.

However, if the machine is equipped with reinforced belts with a 3M tooth pitch, you do not have to worry about these belts tearing during an important job.

Supplier reliability and support

Choosing a supplier is one of the most important factors when buying a laser wood engraver. And the first contact can already tell you a lot about who you are dealing with.

Consulting

A competent supplier will help you make the right choice based on your goals and needs. Do not hesitate to ask questions and listen carefully to the supplier's reasoning. An honest seller will have clear, well-reasoned answers, without vague and unclear language. If they are trying to sell you something you don't really need, look for a more conscientious laser wood engraving machine supplier.

Supplier reliability

The second indirect factor that you should pay attention to is how long the seller has been on the market and whether he has representative offices in different countries or plays only on the regional market. As a rule, if a machine manufacturer has been around for a long time and is active in other regions, this indicates a quality product.

Assistance in learning to use the equipment

This is one of the most important factors, since CNC laser wood engraving machines can be quite difficult to master for people who have not encountered such equipment before. Check whether the company offers advice on the operation of the machine, provides training, and can help with commissioning.

Find out more interesting information about CNC laser machines on our youtube channel.

Warranty and post-warranty service

Specify what the warranty for the equipment will be, how exactly the company will help if something suddenly fails, how soon it can send its specialist or replace the broken part.

Don't forget to ask if the supplier will provide support beyond the warranty period, as good laser wood engravers have a service life of over 10 years and the warranty is usually 1-2 years.

Conclusions

When choosing a laser engraving machine for wood, it is important to know the main parameters by which this machine should be selected. And we hope that this article will help you to choose a machine that will last a long time and give you a good result and high quality work.

If you have any questions or need advice, please contact Virmer managers: +31208082045, info@virmer.com.

FAQ

What is a laser wood engraving machine?

A wood laser engraving machine is a CNC (Computer Numerical Control) equipment that allows you to apply high-precision detailed images and inscriptions on wood materials using laser radiation, as well as to cut them.

How much does a laser wood engraver cost?

The cost of a laser wood engraving machine varies greatly depending on the parameters of the machine and can range from 1369 to 16647 €. The price is influenced by: the size of the working area, the machine body, the laser source, the guide rails, motors, and other accessories.

What wood can be engraved with a laser machine?

With a laser wood engraving machine almost any wood and any wood-based material such as plywood, veneer, MDF, cardboard, and others can be engraved.